Study of the effects of preheating on discharge

May 1, 2024 · For 2.0C discharge cases, the maximum capacity benefit of the battery is obtained with 3 min preheating, which is higher by 6.8 % and 15.1 % than that with 1 and 5 min

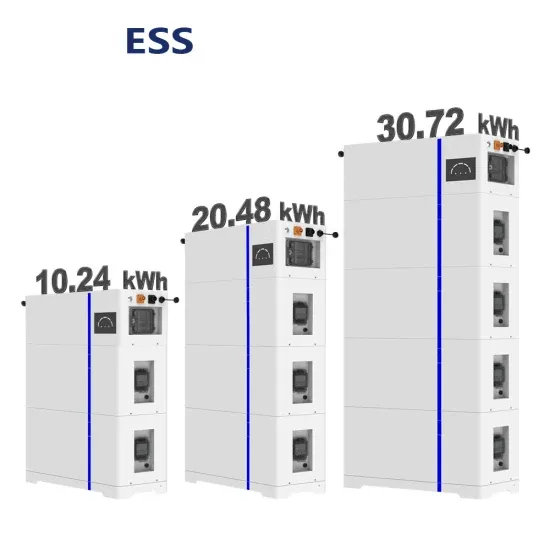

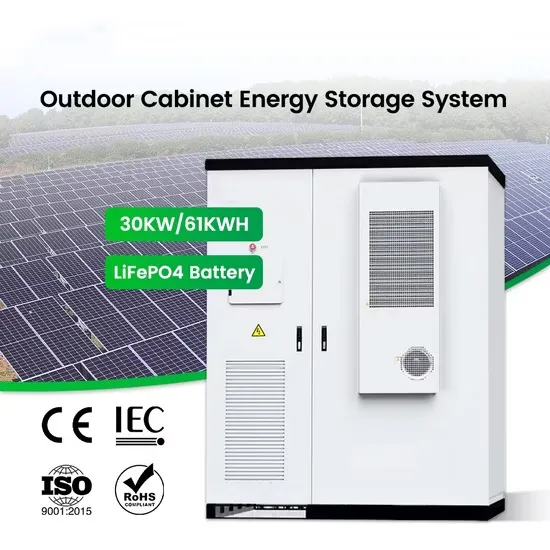

How much does the energy storage battery

Jan 22, 2024 · The price of energy storage battery cabinets can vary significantly depending on various factors. 1. General cost range: The costs typically range

Lithium-ion battery preheating strategy based on on-board

Dec 19, 2022 · In this paper, an internal preheating strategy is presented. The on-board inverter and the three-phase permanent magnet synchronous motor of the EVs are used to form a

How to calculate the heat dissipated by a battery pack?

Aug 22, 2018 · I have a battery pack consisting of 720 cells. I want to calculate the heat generated by it. The current of the pack is 345Ah and the pack voltage is 44.4Volts. Each cell has a

Battery cabinet preheating technology

It can be seen in Fig. 1(c) that the electro-thermal film preheating technology heats the battery by the heat generated when an electric current flows through the electro-thermal film that is cal

Experimental study on liquid immersion preheating of

Aug 1, 2024 · An experimental platform to examine the effects of single-phase immersion preheating on lithium-ion battery performance at low temperatures was set up in this study.

Battery preheating function principle

What is battery rapid preheating control strategy? The battery rapid preheating control strategy has been redesigned to rapidly heat the battery system by disconnecting the rapid charging

Preconditioning of the battery before fast charge

Dec 7, 2023 · My house is close to a Supercharger site and today I wanted to test something : how much %SOC a session of "Preconditioning the battery for

An ultra-fast charging strategy for lithium-ion battery at low

Sep 1, 2022 · Nevertheless, in consideration of battery health, the maximum current rate cannot reach 1 C at subzero temperatures only by regulating the charging protocol. Preheating can

New energy preheating battery principle diagram

Can a self-preheating system preheat a battery pack? Owing to small energy consumption and preheat current during preheating, this self-preheating system could still preheat the battery

How much is the preheating current of the battery cabinet

At a preheating current of 9.6 A, the rate of increase in the temperature of the batteries was 17.14 °C/min, and the maximum temperature difference among the batteries

Advanced low-temperature preheating strategies for power

Nov 1, 2024 · Self-heating LIB are embedded with elements that have a certain resistance inside the battery, and heat is generated when current flows through these elements, thus preheating

Calculating Battery Current | Information by Electrical

Jun 21, 2014 · Seems odd for a cabinet with two 400A breakers. Your current will be controlled mostly by the load. Short circuit current of each string at the breaker is the battery charged

New Energy Battery Cabinet Preheating

The state of the art on preheating lithium-ion batteries in cold In the context of the global energy crisis and environmental pollution, new energy vehicles, especially zero-emission and

What is the normal preheating current of the battery

The preheating process lasted for 23 and 71 swhen using 11 and 9.5 A respectively. The short preheating time was due to the significant polarization of the lithium-ion battery. Large

Electric car battery in winter: Heating, please!

Mar 15, 2022 · Most electric car drivers notice it every winter: Performance at the fast-charging stations drops with the temperatures. Christoph M. Schwarzer

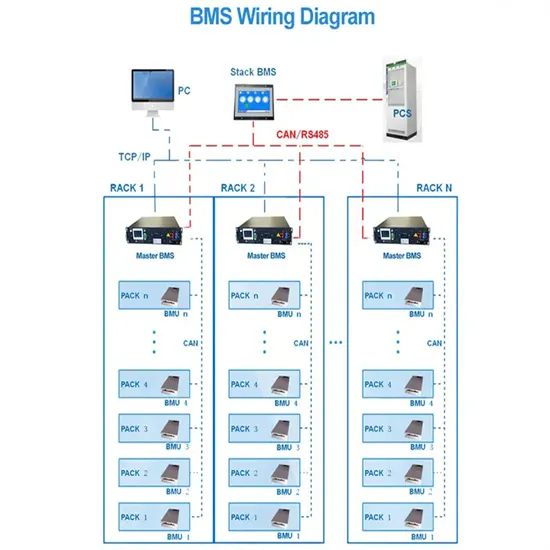

Specifications and requirements for battery cabinets in

o Battery rack/cabinet (if battery modules or Pre-assembled battery system requires external battery racks/cabinets for mechanical mounting/protection). o Balance of system components

A systematic approach for determining the optimal battery preheating

Apr 1, 2025 · This study investigates the effect of preheating cut-off temperature on battery available energy and introduces a systematic approach for determining the optimal battery

Study of the effects of preheating on discharge

May 1, 2024 · The Li-ion battery''s sharp performance decline in the cold restricts the use of electric vehicles. Preheating is a crucial strategy for addressing the issue. The available

Low temperature preheating techniques for Lithium-ion batteries

May 1, 2022 · Therefore, battery preheating techniques are key means to improve the performance and lifetime of lithium-ion batteries in cold climates. To this end, this paper

6 FAQs about [How much is the preheating current of the battery cabinet]

Does preheating improve battery performance under cold weather conditions?

The features and the performance of each preheating method are reviewed. The imposing challenges and gaps between research and application are identified. Preheating batteries in electric vehicles under cold weather conditions is one of the key measures to improve the performance and lifetime of lithium-ion batteries.

How long does a lithium ion battery preheat?

The RTR was found to be 4.29 ℃/min. The preheating process lasted for 23 and 71 s when using 11 and 9.5 A respectively. The short preheating time was due to the significant polarization of the lithium-ion battery. Large discharge current and consequent battery polarization can lead to severe degradation of batteries.

What is AC preheating?

Alternating current (AC) preheating AC preheating is a method that applies an AC with a prescribed frequency and amplitude to the positive and negative electrodes of the battery for generating heat through the internal impedance of the battery [96, 97].

What is the optimal preheating performance of a lithium-ion battery?

Under the premise of ensuring safe operation of the lithium-ion battery, the optimal preheating performance was achieved. The results showed that the RTRs of the battery cell and four series of the battery pack from −20.3 °C to 10.02 °C are 2.21 ℃/min and 2.59 ℃/min, respectively.

Which preheating method is best for EV batteries?

Due to low thermal conductivity and high space requirement, air preheating is only suitable for early generation EVs with low energy density batteries. At the moment, liquid preheating is the most commonly used method since it has demonstrated good preheating performance and consistent temperature distribution.

How long does a battery last in DC preheating?

The battery lifetime in DC preheating was found to be only 81 cycles . With DC heating, the battery can be preheated by directly discharging the energy stored in the battery. Since no additional equipment is required, the cost is low and it is relatively easy to implement.

Update Information

- How much current does a 9v battery in an energy storage cabinet have

- How much current does the energy storage cabinet battery output

- How to control the current of battery cabinet

- How much current does the liquid-cooled energy storage battery cabinet have

- How to connect the ground wire in the battery cabinet

- How much does a battery energy storage cabinet cost in Beijing

- How to build a battery cabinet site

- How to join the site energy battery cabinet

- How to set up automatic entry of battery cabinet

- How to measure the quality of batteries in the battery cabinet

- How long is the warranty period for outdoor communication battery cabinet in Ghana

- How big a battery cabinet can be placed in a medium box

- How much does the battery of the Laayoune energy storage cabinet cost

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.