How to Test Battery Capacity: Comprehensive Guide and

Aug 12, 2024 · With the rapid development of science and technology, batteries, as core components of energy storage, are widely used in mobile phones, electric vehicles, energy

Battery Quality Control: Analytical Techniques

May 16, 2025 · Battery quality control is not limited to electrical performance; it requires rigorous materials testing to verify purity, detect contamination, and

Surface Area Determination of Battery Cathode and

Jul 8, 2023 · battery materials? Surface area is a critical property for battery components including anodes, cathodes, and even separator materials. Surface area differences affect performance

Judge the quality of rechargeable batteries with a multimeter

May 6, 2020 · How to judge the quality of rechargeable batteries with a multimeter?rechargeable batteries manufacturer, lithium-ion battery manufacturer, best li-polymer battery manufacturer

Step-by-Step Battery Capacity Testing Procedure

May 23, 2024 · With our step-by-step procedure, you''ll learn how to precisely evaluate battery capacity. Discover key tools, techniques, & best practices for

Quality Management for Battery Production: A Quality Gate

Jan 1, 2016 · By establishing internal decision points (quality gates), measurement steps can be aggregated, minimizing effort for quality control and summarizing information on relevant

Understanding the Different Types of Battery Test Equipment

Battery analyzers are used to measure capacity, voltage, and internal resistance, ensuring that batteries meet specified standards. Cyclers, on the other hand, are designed to charge and

BU-504: How to Verify Sufficient Battery Capacity

Oct 27, 2021 · A battery maintenance program as part of quality control assures that all batteries in the fleet are within the required performance range. Figure

How to Measure Internal Resistance of a Battery

Feb 1, 2023 · Internal resistance in a lithium-ion battery is a measure of the resistance to the flow of electrical current within the battery. It is caused by

Quality Management for Battery Production: A Quality Gate

Jan 1, 2016 · High costs and large quality fluctuations during the production of high-energy batteries are considered to be among the main impediments of electric cars to succeed on the

Choose the Right Instrument for Your Battery

Sep 7, 2023 · This guide highlights robust and comprehensive testing solutions to unlock the potential of lithium-ion batteries and accelerate battery development.

Making High Quality Open Circuit Voltage

Jun 29, 2022 · For battery quality and other binning applications, higher accuracy means a larger target to hit for the highest quality products since there''s less instrument accuracy to be

Field Guide to Battery Materials Characterization

Aug 16, 2025 · 1.4 ADHESION Lithium-ion batteries are composed of thin metallic electrodes that are coated with either lithium metal oxide or layered carbon. The quality and durability of the

All About Batteries

Jun 3, 2024 · Batteries can be made of multiple cells, so for example, you''ll rarely see a 2V lead-acid battery. Usually they are connected together inside to make a 6V, 12V or 24V battery.

How To Evaluate The Quality Of Solar Batteries?

Oct 16, 2023 · In this article, we explore the various methods used to test the quality of these batteries. Capacity Testing. Step 1: Prepare the solar energy

6 FAQs about [How to measure the quality of batteries in the battery cabinet]

What factors should be considered when testing a battery?

When testing a battery, it is important to consider various factors such as the battery’s voltage, capacity, resistance, and temperature. These parameters help assess the battery’s health and identify any potential issues that may impact its performance. A key aspect of battery testing is understanding the various testing methods available.

How to test a battery?

Once the battery type is identified, the testing procedure can be initiated. It is advisable to follow these steps: Prepare the battery and the testing equipment, ensuring that all connections are secure. Perform a visual inspection of the battery for any signs of damage or leakage.

What is battery capacity testing?

Capacity testing is a fundamental measurement that determines the amount of energy a battery can store and deliver. This test is conducted by fully charging the battery and then discharging it at a controlled rate until it reaches a predetermined endpoint. The capacity of the battery is then calculated by measuring the amount of energy discharged.

What is battery testing?

Battery testing comprises measuring the voltage, capacity, & other parameters of the battery with the help of a multimeter or another equipment. You will be able to tell whether a battery is defective, weak, or needs to be changed based on the results of the tests performed on the battery. What is the purpose of Battery Testing?

How do I choose a good battery?

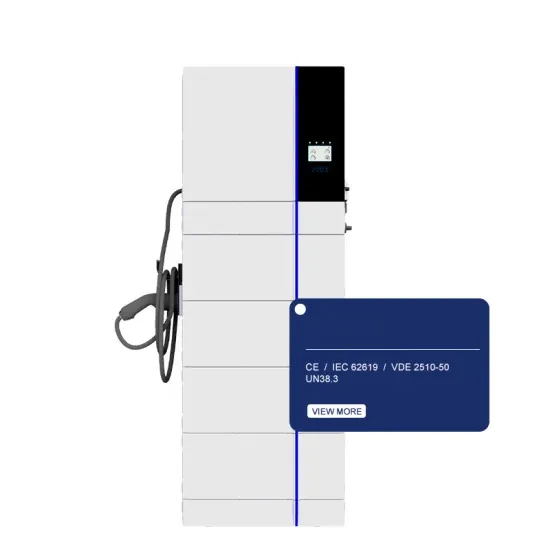

Choosing a reputable brand and a battery that has undergone rigorous quality certifications is an effective way to ensure quality and reliability. International certifications such as ISO, CE, and UL indicate that the battery meets relevant safety and performance standards. When purchasing, prioritize these certified products for peace of mind.

What is battery quality control?

Explore battery quality control techniques used in lithium-ion battery testing, failure analysis, and performance validation across the battery lifecycle. As lithium-ion batteries become integral to technological innovation, quality control has emerged as a key discipline in ensuring their safety, reliability, and performance.

Update Information

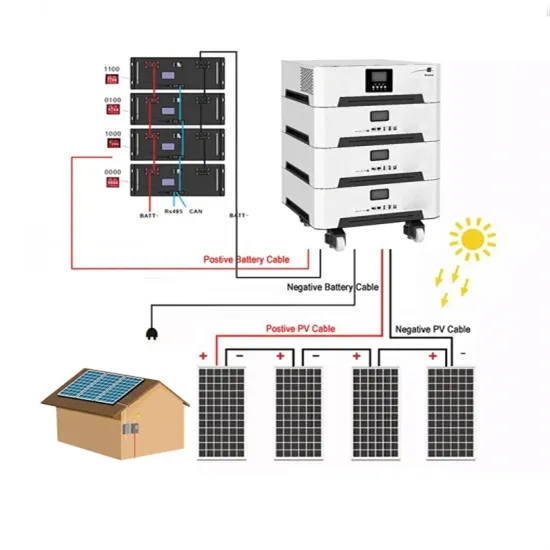

- How to take out the batteries from the battery cabinet

- How is the quality of the portable battery cabinet

- How much does a Swedish outdoor communication battery cabinet cost

- How much is the preheating current of the battery cabinet

- How to use ESS power base station in battery cabinet display cabinet

- Can the batteries in the battery cabinet be used directly

- How to use the mobile energy storage battery cabinet

- How much does it cost to replace a lithium battery station cabinet in Sierra Leone

- How to start the communication network cabinet energy storage battery cabinet

- How long does it take to charge a new energy battery cabinet

- How to delete the battery in Xiaomi Energy Storage Cabinet

- How to install photovoltaic communication battery energy storage cabinet

- How long is the warranty period for outdoor communication battery cabinet in Ghana

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.