What are the Essential Site Requirements for Battery Energy

Nov 19, 2024 · Whate are the key site requirements for Battery Energy Storage Systems (BESS)? Learn about site selection, grid interconnection, permitting, environmental considerations,

Battery Energy Storage Cabinet Construction Process: From

Let''s be real - when most people hear "battery energy storage cabinet construction process," they picture workers bolting together metal panels like IKEA furniture on steroids.

19 DIY Battery Box Projects: How To Build A Battery Box

Feb 11, 2022 · That being said, it is possible to build a safe and working battery box at home. For the most part, all you need are the right tools and materials for the job and some basic

HOW TO BUILD A BATTERY STORAGE CABINET

How much does it cost to repair the energy storage battery panel In the cost table, we have estimated battery costs based on typical battery output as follows: battery power 7kW peak /

How to Build a Solar Battery Box: A Comprehensive Guide

Jan 2, 2025 · Discover the ultimate guide to building your own solar battery box and harness the power of renewable energy! This article outlines the essential tools and materials you need,

building your own storage rack for server batteries.

Oct 30, 2024 · I saw a video by Will Prowse using a Dewalt metal rack for server rack battery storage. If you use a metal cabinet or build your own, do you

How to Install and Set Up a Battery Storage Cabinet at Home

Apr 19, 2025 · Discover the components and benefits of battery storage cabinet systems, including lithium-ion advantages, placement considerations, ventilation needs, and cost

Best enclosure for batteries outside

May 27, 2020 · Right now I have 22KWH of LiFePo4 batteries in my garage. I want to move them out to the backyard right behind the garage. The main reason for this is I want my garage

How to correctly install lithium battery energy

Mar 25, 2024 · In this guide, we will introduce the correct installation steps after receiving the lithium battery energy storage cabinet, and give the key steps

DIY Insulated Battery Box

Aug 29, 2023 · I also don''t have a lot of space in the closet where the batteries are stored. With all of the great resources on this forum (special shoutout to Horsefly) on DIY battery packs, I

How to Build a Lithium Ion Battery Box: Essential Tips and

Feb 21, 2025 · Building a lithium-ion battery box requires careful planning and execution to ensure safety and efficiency. By understanding the essential components, choosing the right

Seeking advice on a the need for a fire-resistant cabinet for Li

Jun 19, 2020 · Yes, the LiFePO4''s I knew to be substantially safer than Li-Ion but, my understanding is that Mostly Harmless was building a Li-Ion battery and looking for fire-safe

How to Build a Battery Room for Lithium-ion,

Jun 24, 2025 · Build a safe, efficient battery room for lead-acid, lithium-ion & EV batteries. Learn layout, ventilation & charging tips to maximise safety &

How to Build a Plywood Battery Box for a DIY

May 15, 2017 · Modern AGM batteries are uber-safe, but there are still many good reasons for a battery box. See how we built a plywood battery box for our van

6 FAQs about [How to build a battery cabinet site]

How to build a battery cabinet?

Step 1: Use CAD software to design the enclosure. You must specify all features at this stage. Step 2: Choose suitable sheet metal for the battery box. You can choose steel or aluminum material. They form the perfect option for battery cabinet fabrication. Step 3: With the dimension from step 1, cut the sheet metal to appropriate sizes.

How to install a battery storage cabinet?

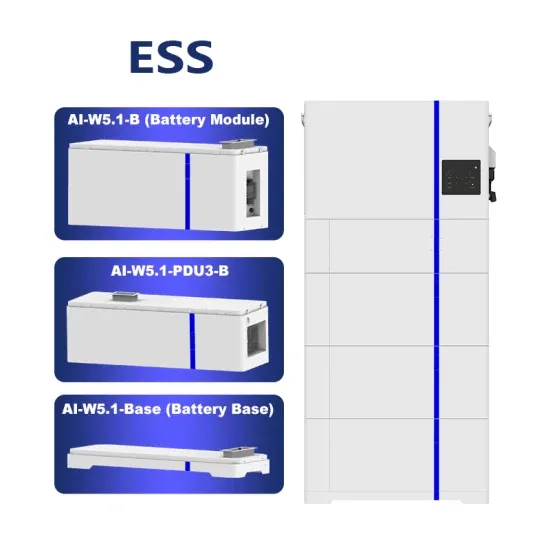

Mounting mechanism – they vary depending on whether the battery storage cabinet is a pole mount, wall mount, or floor mount. The mechanism allows you to install the battery box enclosure appropriately. Racks – these systems support batteries in the enclosure. Ideally, the battery rack should be strong.

How do you choose a battery cabinet?

Again, the door should have a safe locking mechanism or latch. In more advanced battery cabinets, they may have alarm systems. Ventilation systems – they may integrate louvers. Depending on the enclosure design, the ventilation systems can be at the top or bottom section. Ventilation systems also help during the cooling process.

How to make a battery box enclosure?

The process involves shaping sheet metal into a battery box enclosure. You can use this method to fabricate any enclosure size or design. Let’s quickly look at the process: Step 1: Use CAD software to design the enclosure. You must specify all features at this stage. Step 2: Choose suitable sheet metal for the battery box.

What are the parts of a battery storage cabinet?

Let’s look at the most common parts: Frame – it forms the outer structure. In most cases, you will mount or weld various panels on the structure. The battery storage cabinet may have top, bottom, and side panels. Door – allows you to access the battery box enclosure. You can use hinges to attach the door to the enclosure structure.

Do battery cabinet enclosures have a DIN rail?

Many enclosures have DIN rail. Electronic components –modern battery cabinet enclosures have sensors for smoke, shock, humidity, temperature, and moisture. These are safety measures to ensure the environment within the battery cabinet is safe. However, such enclosures are costlier.

Update Information

- How to make a good battery cabinet site

- How is the energy battery cabinet at the Tbilisi site

- Solar power generation battery cabinet outdoor site

- Outdoor battery cabinet color matching outdoor site

- How to choose a good-looking color for the battery cabinet

- What does esc represent at the battery cabinet site

- How much is the lithium battery replacement cabinet in Northern Cyprus

- How to replace the lithium battery in Cairo outdoor communication battery cabinet

- How is the quality of the portable battery cabinet

- How much does the battery cabinet main control box cost

- How to start the communication network cabinet energy storage battery cabinet

- How to discharge the battery cabinet in the substation quickly

- Lithium battery site cabinet energy storage liquid cooling

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.