How to Build Your Own Lithium Battery Pack: A Step-by-Step

Feb 9, 2025 · From powering gadgets to supporting renewable energy systems, building your own lithium battery pack can be a cost-effective and satisfying project. Whether you aim to use it for

How to Build a Custom Lithium Battery Pack?

Feb 5, 2024 · Discover the essentials of creating a custom lithium battery pack, including defining requirements, choosing cell types, designing configurations, and ensuring safety. This

Leading Battery Pack Manufacturers in China: A

May 4, 2025 · Fun Fact: Lishen has been a pioneer in the battery industry for over two decades, consistently pushing the boundaries of what''s possible with

Design of power lithium battery management system based

Mar 1, 2022 · Although power lithium-ion batteries are widely used, there are many problems in the process of use, such as: overcharging and discharging lead to high battery temperature

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Feb 15, 2025 · Among various energy storage technologies, lithium-ion battery packs have emerged as the preferred choice due to their high energy density, long cycle life, and

Open-source database for lithium-ion batteries

Mar 7, 2023 · The "BetterBat" research project has released an open-source database of over 300 lithium-ion battery cells from various manufacturers, with

LITHIUM ION BATTERY

Nov 3, 2020 · A lithium-ion battery or Li-ion battery (reviated as LIB) is a type of rechargeable battery. Lithium-ion batteries are commonly used for portable electronics and electric vehicles

Life cycle assessment of lithium-based batteries: Review of

Dec 1, 2024 · The lithium-ion battery pack with NMC cathode and lithium metal anode (NMC-Li) is recognized as the most environmentally friendly new LIB based on 1 kWh storage capacity,

National Blueprint for Lithium Batteries 2021-2030

Jul 1, 2024 · A robust, secure, domestic industrial base for lithium-based batteries requires access to a reliable supply of raw, refined, and processed material inputs along with parallel efforts to

Battery Pack – Aa Lithium Energy

Jan 21, 2025 · A battery pack is a collection of individual batteries or cells assembled together to provide power to electronic devices, vehicles, or systems. They are designed to deliver a

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

Strengthening USA''s Domestic Lithium-ion

Feb 26, 2024 · This project is one of many projects benefitting from these efforts, and it will strengthen the domestic lithium-ion battery manufacturing base and

Ganfeng Lithium Plans to Build China''s Largest Solid-State Battery

Aug 1, 2022 · The 630-mu (420,000-square-meter) site, with a total floor area of 570,000 square meters, includes three projects: a solid-state battery technology research institute, a solid-state

Ganfeng Lithium''s 12GWh Energy Storage Battery PACK Project

Jun 26, 2025 · Since the official start of construction in February 2025, the project has progressed rapidly, aiming to become an advanced manufacturing base that integrates next-generation

How to Build Your Own Lithium Battery Pack: A Step-by-Step

Feb 9, 2025 · Conclusion Building your own lithium battery pack can be an incredibly rewarding project, providing you with a tailored power source for various applications. By following this

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · , this brochure presents the process chain for the production of battery modules and battery packs. The individual cells are connected in series or parallel in a module. Several

Lithium-ion battery data and where to find it

Sep 1, 2021 · Lithium-ion batteries are fuelling the advancing renewable-energy based world. At the core of transformational developments in battery design, modelling and management is

How to Build a Powerful 24V Lithium-Ion Battery Pack from

4 days ago · Building a 24V lithium-ion battery pack from scratch can be a rewarding and cost-effective project. Whether you''re a hobbyist or a DIY enthusiast, creating your own battery

The Construction of a Lithium-Ion Battery Pack: An In-Depth

Jun 19, 2025 · From electric vehicles to portable electronics, these batteries are renowned for their efficiency, energy density, and longevity. This article delves into the intricate construction

6 FAQs about [Lithium battery pack base project]

What is a lithium-ion battery pack?

Among various energy storage technologies, lithium-ion battery packs have emerged as the preferred choice due to their high energy density, long cycle life, and lightweight properties. In this blog post, we will delve into the key steps and considerations involved in designing a lithium-ion battery pack.

How safe is a lithium-ion battery pack?

Safety is paramount in lithium-ion battery pack design. Here are some key safety considerations: Overcharge Protection: Implement safeguards to prevent overcharging, which can lead to thermal runaway and fire. Over-Discharge Protection: Prevent cells from discharging below their safe voltage limit to avoid permanent damage.

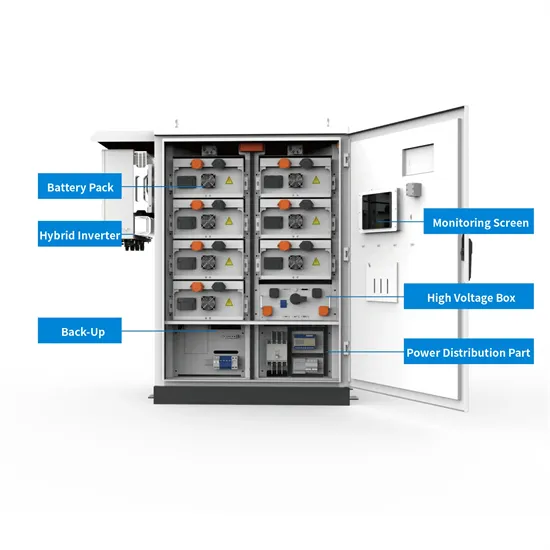

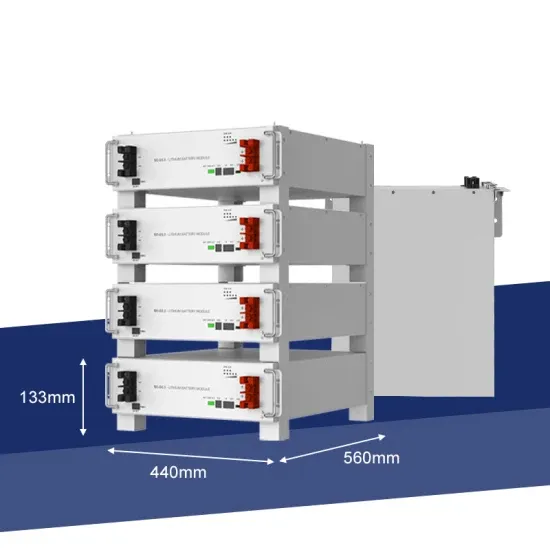

What are the components of a battery pack?

Cells: The basic building blocks of a battery pack. Lithium-ion cells come in various shapes (cylindrical, prismatic, pouch) and chemistries (e.g., NMC, LFP). Modules: Groups of cells assembled together in a specific configuration (series, parallel, or a combination) to achieve the desired voltage and capacity.

What is the production process of lithium-ion battery cells?

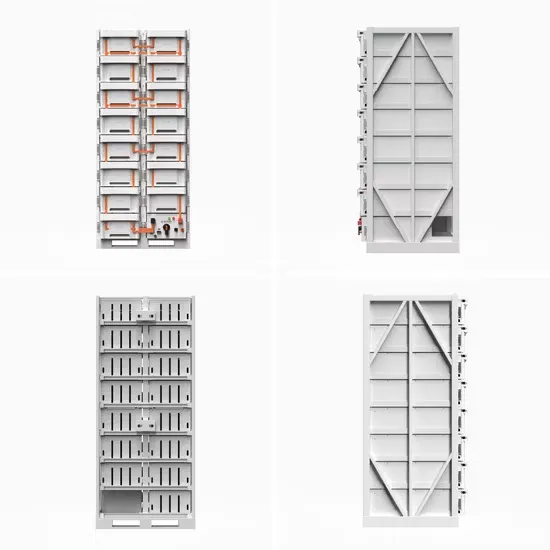

"Production process of lithium-ion battery cells" , this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain

What is the process chain for the production of battery modules?

, this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain Overview of the production sequence from cell to system

Are competencies transferable from the production of lithium-ion battery cells?

In addition, the possible transferability of competencies from the production of lithium-ion battery cells is illuminated. 2ndedition ISBN 978-3-947920-29-7 Ed. PEM of RWTH Aachen University & VDMA

Update Information

- North Korea pack lithium battery project

- Papua New Guinea Small Base Station Equipment Lithium Ion Battery Project

- European lithium titanate battery pack

- Tehran lithium battery station cabinet base station

- East Africa Lithium Battery 24V Battery Pack

- Base station intelligent lithium battery

- Lithium battery pack manufacturer in Nairobi

- Paris lithium battery pack quotation

- Lithium battery pack parallel box

- Austria ups power lithium battery pack

- Large capacity 26650 lithium battery pack

- Botswana lithium battery pack

- Lithium battery pack leading enterprise

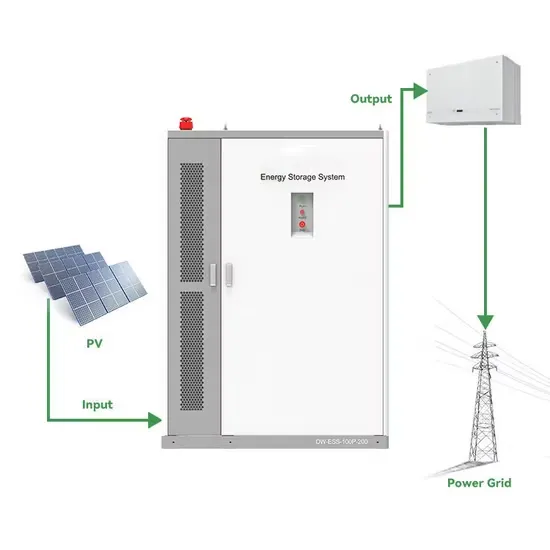

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.