Solar Panel Lamination Process Explained

Dec 30, 2024 · The laminated solar panel is a photovoltaic (PV) module that can resist long-term weather exposure without sacrificing energy generation efficiency. Learn more about the solar

Lamination process in solar panels

Aug 31, 2021 · Lamination process in solar panelsWith the improper lamination of the solar module, it''s not possible to withstand harsh environment and give flawless performance till 25

Modular Tempering Solution: Scalable for Solar & Laminated

Jul 3, 2025 · Modular Tempering Solution: Scalable for Solar & Laminated Glass, Find Details and Price about Glass Tempering Machine Glass Tempering Furnace from Modular Tempering

Small Solar Panel Equipment Oil Pump Heating Laminate Solar

Jun 23, 2025 · Small Solar Panel Equipment Oil Pump Heating Laminate Solar Module, Find Details and Price about Solar Panel Machine Semi Automatic Laminator from Small Solar

Encapsulated Lamination Photovoltaic Laminate Solar Power Equipment

Oct 27, 2024 · Encapsulated Lamination Photovoltaic Laminate Solar Power Equipment Manufacturers, Find Details and Price about PV Cell Module Laminator Vacuum Laminator

Laminated solar panel equipment production process

As solar panels are exposed and subject to various climatic impact factors,the encapsulation of the solar cells through lamination is a crucial step in traditional solar PV module

Insulation Aluminum Foil Ceramic High for Container House Split Solar

May 10, 2025 · Insulation Aluminum Foil Ceramic High for Container House Split Solar Water Heater Single Side Laminate Roof of Glass Wool Roll, Find Details and Price about Aluminum

PE/Pet/VMPET/LDPE Laminated Heat Sealing Aluminum Foil

Aug 19, 2025 · PE/Pet/VMPET/LDPE Laminated Heat Sealing Aluminum Foil for Shipping Container Liner Cage Guide and Machine Equipment Packaging, Find Details and Price about

Laminate Making Machine Auto Feeding Laminator Vacuum Laminator

Feb 26, 2025 · Laminate Making Machine Auto Feeding Laminator Vacuum Laminator, Find Details and Price about Solar Panel Manufacturing Equipment Solar Module Laminator from

Full automatic solar panel laminator solar cell laminator

Laminate the raw material (Back sheet-EVA-solar cells-EVA-Glass) into the solar panel, it works automatic online. - Full Auto Solar Panel Making Machines - Ooitech, Full Automatic solar

Laminated solar panel equipment production process

Solar module lamination: Place the laid solar module in the laminator, evacuate the air from the solar module by vacuuming, then heat to fuse the EVA to bond the solar cell, glass and

Laminator Machine China Solar Energy Products PVB Laminated

Aug 18, 2025 · Laminator Machine China Solar Energy Products PVB Laminated Glass Machine, Find Details and Price about Solar Panel Manufacturing Equipment Solar Module Laminator

Solar Panel Lamination: procedure, advantages and

Dec 30, 2024 · Learn more about the solar panel lamination process, its benefits, and the unique value of Bent River''s photovoltaic module laminator. Solar cells efficiently convert solar energy

Insulation Aluminum Foil Ceramic High for Container House Split Solar

Apr 9, 2025 · Insulation Aluminum Foil Ceramic High for Container House Split Solar Water Heater Single Side Laminate Roof of Glass Wool Roll, Find Details and Price about Prefab

6 FAQs about [Laminate production for container solar equipment]

What is a solar laminator photovoltaic module?

Solar Laminator photovoltaic module. Lamination is one of the most critical processes in solar panel manufacturing; it ensures the quality and durability of the photovoltaic module. We can offer customised laminators to suit all production needs. Laminates the module components applying the right pressure and temperature.

Why do solar panels need a customised laminator?

Lamination is one of the most critical processes in solar panel manufacturing; it ensures the quality and durability of the photovoltaic module. We can offer customised laminators to suit all production needs. Laminates the module components applying the right pressure and temperature. Customised solutions for all technologies in the solar market

What is a laminated solar panel?

The laminated solar panel is a photovoltaic (PV) module that can resist long-term weather exposure without sacrificing energy generation efficiency. Learn more about the solar panel lamination process, its benefits, and the unique value of Bent River’s photovoltaic module laminator.

How to laminate solar panels?

As solar panels are exposed and subject to various climatic impact factors, the encapsulation of the solar cells through lamination is a crucial step in traditional solar PV module manufacturing. At this moment, the most common way to laminate a solar panel is by using a lamination machine.

How many solar panels can a laminator accommodate?

Bigger size The laminators can be customized to have a big effective lamination area up to 2,900*12,500mm which is 34% larger than the conventional laminator. Our laminators can accommodate eight 2,600*1,450mm panels, and can laminate up to nine 182mm solar panels at a time, which means 2 more panels than conventional laminators on the market.

Why is solar panel lamination important?

Solar panel lamination is crucial to ensure the longevity of the solar cells of a module. As solar panels are exposed and subject to various climatic impact factors, the encapsulation of the solar cells through lamination is a crucial step in traditional solar PV module manufacturing.

Update Information

- Energy storage container solar photovoltaic module factory photothermal equipment

- Praia automatic solar photovoltaic panel production equipment

- Analysis of the pros and cons of solar energy storage container equipment

- Solar photovoltaic folding container liquid cooling equipment

- Energy storage container production equipment manufacturers ranking

- Solar power generation system dual container controller

- Distance between solar panels and container

- Solar container design

- East Africa Solar System Equipment

- Home energy storage equipment brand new solar photovoltaic

- There is a big gap between the container and the solar panels

- What are the solar energy equipment on site

- Photovoltaic solar energy installation in container carport

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

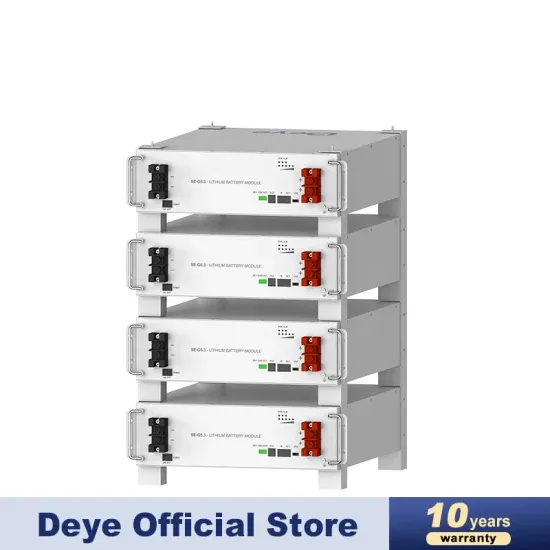

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.