STORAGE AND UNPACKING INSTRUCTION OF

Jan 9, 2025 · In order to prevent the safety of placing and unpacking modules affected by tilt and uneven ground, please choose flat ground when unloading. When unloading on the platform or

Skill: How to correctly and safely unload the

Jan 15, 2024 · Skill: How to correctly and safely unload the solar panel pallets from containers? Shinefar Solar Solar Excellence in Every Ray Published Jan

Calculation of Solar Panel Spacing for India (New

Dec 2, 2017 · Now we are ready to calculate the distance between the panels. D = h / tan (Inclination) = 0.50 / tan (22.33) = 1.22 m (this is the distance without

How to calculate the minimum distance between PV panels

When installing solar panel systems, it is crucial not only to consider the spacing between panels and installation angles but also to comply with local government and regulatory requirements

Installing Solar Panels on Shipping Containers: How-To

Apr 2, 2025 · Standard solar panels are typically about 1m, (3.25ft) wide and 1.9m (6.25) ft tall, with each panel covering around 17.55 sq ft. The container''s rooftop area measures

How Far Can I Run My Solar Panel Cables & And

May 18, 2023 · The distance between your solar panel and battery will affect how efficiently your system works. Longer wiring distances can cause voltage drop,

How much gap should be left between photovoltaic panels

The distance between two rows of solar panels should be five to six inches. This is how far apart should solar panels be. It is also recommended that you leave 1 to 3 feet of space between

How To Ship Solar Panel Arrays

Aug 17, 2025 · What is the difference between FCL and OOG shipping? FCL (Full Container Load) is used when your cargo fits within a standard shipping container. OOG (Out of Gauge)

Distance Limitations for Solar Panels: A Comprehensive

Aug 19, 2025 · Comprehensive analysis of solar panel distance limits: Learn wiring impacts, efficiency tips, and installation strategies for optimal energy output.

Panel row spacing, the space race | Greenwood

Aug 13, 2025 · As a commercial solar system is offered as a financial option to negate a certain amount of electricity drawn from the electrical grid it makes no sense to design a system that

Installing Solar Panels on Shipping Containers:

Apr 2, 2025 · Thinking of adding solar panels to your shipping container? Learn key considerations, how many panels fit on 20ft and 40ft containers, plus tips

Packaging Datasheet1

Jan 9, 2025 · When the goods go out of the container port, please slow down, and lower the height of the forklift arm from the ground (it is recommended to close to the bottom plate to

How Many Solar Panels Will Fit in a Shipping

Mar 24, 2025 · When it comes to shipping solar panels, efficiency is everything. As a solar supplier, installer, or business leader who wants to ship panels by

Distance Limitations for Solar Panels: A Comprehensive

Aug 19, 2025 · The distance limitations of solar panels are crucial factors in their efficiency and performance. To maximize their energy production, solar panels need to be installed in

6 FAQs about [Distance between solar panels and container]

How many solar panels are in a shipping container?

Standard solar panels are typically about 1m, (3.25ft) wide and 1.9m (6.25) ft tall, with each panel covering around 17.55 sq ft. The container's rooftop area measures approximately 14.4m2 (155 sq ft) A 20ft shipping container can typically accommodate 6 to 12 solar panels, depending on panel size and mounting configuration.

How much space should be between two solar panels?

It is best to leave four to seven inches of space between two solar panels. Again, this accommodates the solar panels’ expansion and contraction during the day. How Much Gap Should Be Between Solar Panel Rows?

How many solar panels can a 20ft container hold?

A 20ft container can fit 6 to 12 panels (approx. 2.4–4.8 kWp), while a 40ft container can hold 12 to 24 panels (approx. 4.8–6 kWp), depending on setup and efficiency. Flexible as well as sturdy mounting solutions like Domino Clamps and Unistrut framing make installation easier without damaging the container.

How much gap should be between solar panels?

The gap between the last row of solar panels and the roof’s edge should be a minimum of 12 inches or one foot. This ensures the panels are accommodated as they expand and contract during the day. See also: Mounting Solar Panels: A Complete Beginner’s Guide to Installation How Much Gap Should Be Between Two Solar Panels?

Do solar panels need to be secured to a container?

The solar panels and frame need to be safely secured to the container to withstand local environmental conditions. The weight of the panels and frame should rest on the corner castings and top side rails of the container and not on the roof panels.

How much space do PV panels need?

On the average roof, the space for your rafters is equal to 16 inches. The standoffs have a 48-inch space between each of the posts. This means that if you decide to install four PV modules that each measure 65 x 39 inches, the total dimension equals 160 inches. So, if your rail is 160 inches long or more, you’ll have enough room for your panels.

Update Information

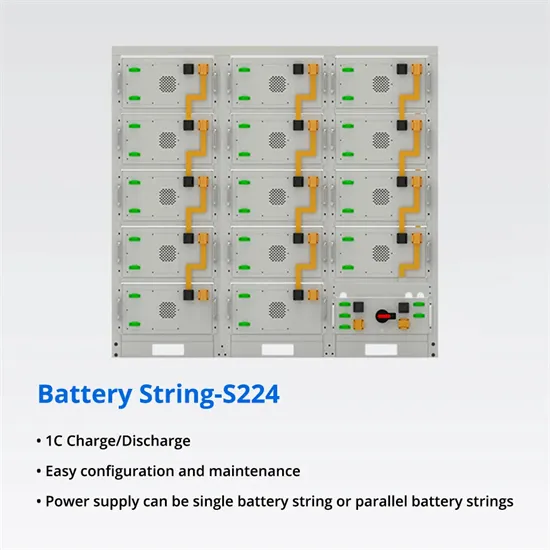

- Solar panels connected to power storage container box

- How to install solar panels on container roof

- Install solar panels in container house

- Small container for solar panels

- Photovoltaic and solar panels can be used together

- How many solar panels does 70 watts have

- Sana a Professional Solar Photovoltaic Panels

- A company that makes solar panels for communication base stations

- How to open the photovoltaic container with solar energy

- Castries Solar PV Panels

- Berne bus station equipped with solar photovoltaic panels

- Container foldable solar charging panel

- German photovoltaic solar panels

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.