Improved overmodulation technique for enhancing torque

Feb 19, 2021 · The overmodulation operation of a three-phase inverter can enhance the output torque capacity of the AC motors. In this case, the enhancement varies depending on the

Guide to Frequency Inverters: Optimizing Motor

Nov 13, 2024 · I. Introduction to Frequency Inverters (VFDs) Frequency inverters, also known as variable frequency drives (VFDs), are essential components in

Motor Drives

Dec 27, 2024 · Today, in motor applications, there is increasing demand for higher power density in terms of the amount of power, volume, and weight that the inverter can transfer to the motor

HowTo: Increase Motor Power Output and Speed by 73%

A 73% increase in Speed and Power is available from most all small AC motors. The same for larger motors when purchased with a special winding. Simply use a 230V x 50Hz motor at

Inverter controlled electric motor, how much

Sep 7, 2023 · It mainly consists of two parts: the main circuit (rectifier module, electrolytic capacitor and inverter module) and the control circuit (switching

CSM_Inverter_Selection_TG_E_2_1

Oct 23, 2012 · Please make use of the Servo Motor selection software, which can calculate the motor shaft conversion inertia and effective/maximum torque, as above. Motor Selection

Technical Article: Power Measurement in the

Aug 10, 2023 · Two key challenges facing electrification are increasing the efficiency of motor drive systems and decreasing their size. To resolve these issues, it is necessary to accurately

Energy efficient optimization for multi-motor system with

Jul 1, 2025 · Implementing high-efficiency motors and inverter driving systems can improve industrial energy efficiency and enhance societal sustainable development. This study

AC Motor Inverters: How They Work, Principles, And

May 19, 2025 · AC motor inverters are devices that convert direct current (DC) into alternating current (AC) to control the speed and torque of electric motors. They are essential for

Traction Inverters A Driving Force Behind Vehicle

Apr 1, 2023 · The careful design of traction inverters for hybrid electric vehicles (HEVs) and electric vehicles (EVs) can help enable faster motor speeds, higher eficiency and a smaller

CSM_Inverter Selection_TG_E_1_1

Oct 23, 2012 · Enable the deceleration stall prevention (enabled in factory settings) (It will automatically increase deceleration time not to cause an overvoltage to stop the motor).

Regeneration in Variable Frequency Drives and Energy

Mar 25, 2017 · Abstract - When an induction motor is driven by a variable frequency drive, electric power delivered from the supply is regenerated back while the motor decelerates by applying

Inverters: Boosting AC Motor Performance for Enhanced

Jun 3, 2025 · An inverter for an AC motor converts direct current (DC) to alternating current (AC). It controls the motor''s speed and torque by adjusting the power frequency. This device

Running A Small AC Motor From An Inverter: The Power Of

Jun 19, 2025 · You can successfully run a small AC motor using a modified sine wave inverter by ensuring the inverter''s output matches the power requirements of the motor and by

Can You Connect Two Inverters in Parallel? (Why

Feb 13, 2024 · Inverters can be connected in parallel to increase the available output power. This is done by connecting the positive terminal of one inverter

How Three-Phase Integrated GaN Technology

Jun 6, 2024 · With advancements in wide band-gap technology, however, gallium nitride (GaN)-based power switches in motor drives can help increase power density, power delivery and

Running Inverters in Parallel: A Comprehensive

Jul 14, 2023 · Additionally, running inverters in parallel can improve system reliability and redundancy. If one inverter fails, the others can continue to

A technical review of modern traction inverter systems used

Nov 1, 2023 · This article presents a comprehensive review of modern traction inverter systems, their possible control strategies, and various modulation techniques

Frequently Asked Questions About Power Inverters

Frequently Asked Questions about Power Inverters. Get answers to all of you power inverter questions including what a power inverter is and what it can be used for, how to size and

6 FAQs about [Inverter that can increase motor power]

Why do you need an inverter for a motor?

Inverters offer comprehensive control over the motor’s speed and torque by adjusting the frequency and voltage of the AC supply. The inverter can provide a smooth start and stop of the motor, as well as providing speed control. This capability not only enhances energy efficiency but also allows for more precise and adaptable motor performance.

What is AC motor inverter?

AC motor inverters are devices that convert direct current (DC) into alternating current (AC) to control the speed and torque of electric motors. They are essential for improving energy efficiency in various applications, such as fans, pumps, and conveyor systems. 1. Functionality 2. Types 3. Applications 4. Benefits 5. Considerations

How do inverters control motor speed?

Frequency control: Inverters adjust the frequency of the output AC signal, which directly controls the speed of the motor. The principle of frequency-to-speed relationship indicates that increasing frequency increases motor speed.

What is an electric motor inverter?

In electric motors, inverters can play a crucial role in regulating performance and efficiency. An inverter, also known as a variable frequency drive (VFD), is a device that converts alternating current (AC) to direct current (DC) and then back to AC at a desired frequency and voltage.

What are the advantages of AC motor inverters?

AC motor inverters offer multiple advantages, including improved energy efficiency, flexibility in control, and reduced maintenance costs. The advantages of AC motor inverters present a compelling case for their use in various applications, yet it is essential to understand the specifics of each benefit.

How do EV inverters work?

EV inverters, also known as traction inverters, convert the dc electricity from the battery into the three-phase variable frequency ac that’s needed to drive the motor at a given speed (Figure 1). EVs use asynchronous (induction) motors or sometimes synchronous motors.

Update Information

- Inverter connected to motor power

- Increase the output power of household inverter

- Bosnia and Herzegovina Photovoltaic Power Inverter Manufacturer

- What is the grid-connected power of the inverter

- Solar inverter high power 6000w all-in-one machine

- Inverter power components

- High quality wholesale 200w power inverter manufacturer

- Single power inverter price

- Charging inverter sine wave power frequency inverter

- 650w rated power inverter

- Industrial and commercial inverter power

- Small to large inverter power

- Energy storage power station inverter structure

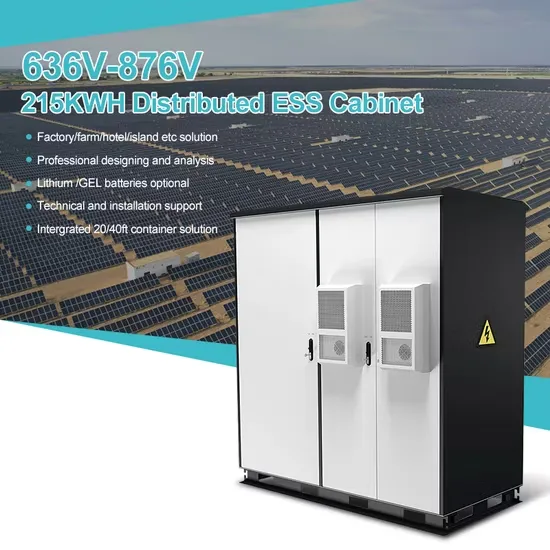

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.