Electric Motor Inverter Explained

Jun 23, 2025 · Understanding the inverter''s role is crucial. It converts the battery''s direct current (DC) into the alternating current (AC) needed by the motor, controlling torque, speed, and

Can I connect three phase frequency inverter to single phase power?

Example: An application has a 230 VAC single phase input power source and needs to connect it to a conveyor that has a frequency inverter connected to a 10 Horsepower 230 VAC 3 phase

PWM Dual Current Source Inverter Connected in Parallel

A dual current source inverter for an induction motor drive is presented in this paper. The dual inverter consists of two inverters connected in parallel and has single a dc power source. The

How Inverter Drives Control AC Induction Motors

Mar 17, 2025 · Inverter Drives, often referred to as Variable Frequency Drives (VFDs), are pivotal in modern industrial automation. These devices are designed to control the speed and torque

Starting an Inverter with load connected

Aug 12, 2021 · The warning is simply for customers with multiple connected loads, who aren''t considering the combined inrush of everything that''s connected. Given your load you should

How an Inverter Drive Works and Controls the Speed of an AC Induction Motor

An Inverter Drive (VFD) works by taking AC mains (single or three phase) and first rectifying it into DC, the DC is usually smoothed with Capacitors and often a DC choke before it is connected

A solar PV water pumping solution using a three-level cascaded inverter

Dec 1, 2016 · The proposed system consists of solar PV array, three-level cascaded inverter (with Inverter-1 and Inverter-2 which are conventional two-level inverters connected in cascaded

How to Connect an Inverter to a Motor: Step-by-Step Guide

Nov 3, 2023 · Whether you want to run a motor on a solar power system or need to convert DC power to AC, the process of connecting an inverter to a motor can be a bit daunting. Fret not,

3-phase PMSM Motor Control Power Inverter Module

Feb 1, 2024 · The application note describes an example of motor control design (EV-INVERTERHD) using the NXP family of automotive motor control MCUs based on a 32-bit

Frequently Asked Questions About Power Inverters | Mingch

Jun 27, 2025 · A power inverter converts electricity from a battery or solar panel (DC) into the type of power used by most appliances (AC). It''s essential for running electronics during road trips,

Three-phase inverter reference design for 200-480VAC

May 11, 2022 · As the IGBT can float with respect to ground at the power stage, both the power supply and the gate circuitry should be isolated from the inverter ground. Isolated current

Can I connect car alternator directly to the invertor

Apr 19, 2017 · I am guessing you are talking about feeding a 12 to 240 volt inverter to power a mains heater. If this is the case forget using a car alternator connected to a wind powered fan

AC Motor Inverters: How They Work, Principles, And

May 19, 2025 · In PWM, the inverter switches the power on and off rapidly, simulating an effective voltage. This method allows the inverter to control the required output efficiently. AC motor

What does a power inverter do, and what can I use one for?

The inverter draws its power from a 12 Volt battery (preferably deep-cycle), or several batteries wired in parallel. The battery will need to be recharged as the power is drawn out of it by the

Electric Motor Power Measurement and Analysis

By Bill Gatheridge, Product Manager, Power Measuring Instruments, Yokogawa Corporation of America Part 1: Basic Electrical Power Measurements Electric motors are electromechanical

Single inverter drive operating multiple motors | Eng-Tips

Apr 27, 2007 · Yeah, I have, but the swithgear I used to connect the different motors was in at least one instance just 2 disconnect switches fed from the drive, and the guy that ran things

AC Motor Inverters: How They Work, Principles, And

May 19, 2025 · AC motor inverters utilize pulse width modulation (PWM) to create a variable voltage and frequency. In PWM, the inverter switches the power on and off rapidly, simulating

How does a motor inverter work?

Jul 23, 2024 · There are three basic working modes of motor inverter: voltage mode, current mode and torque mode. Among them, the voltage mode and current mode are to control the motor

Inverter to Motor Wiring

Jan 19, 2011 · If your motor was originally wired to an industrial three phase supply it is likely that the motor voltage is wired for 400V. The inverter will run the motor without harm, but the

6 FAQs about [Inverter connected to motor power]

How does an inverter control a motor?

An inverter uses this feature to freely control the speed and torque of a motor. This type of control, in which the frequency and voltage are freely set, is called pulse width modulation, or PWM. The inverter first converts the input AC power to DC power and again creates AC power from the converted DC power using PWM control.

How does an inverter work?

The inverter first converts the input AC power to DC power and again creates AC power from the converted DC power using PWM control. The inverter outputs a pulsed voltage, and the pulses are smoothed by the motor coil so that a sine wave current flows to the motor to control the speed and torque of the motor.

What is AC motor inverter?

AC motor inverters are devices that convert direct current (DC) into alternating current (AC) to control the speed and torque of electric motors. They are essential for improving energy efficiency in various applications, such as fans, pumps, and conveyor systems. 1. Functionality 2. Types 3. Applications 4. Benefits 5. Considerations

How do motor drive inverters and high-power converters work?

Motor drive inverter circuits and high-power converters use a bridge circuit configuration, which consists of semiconductor switches for the high voltage side and the low voltage side. A stable power supply is required for driving these semiconductor switches.

How do transistors work in AC motor inverters?

Transistors serve critical functions in AC motor inverters by controlling the conversion of direct current (DC) to alternating current (AC). They take on the role of switching devices, enabling efficient modulation of voltage and current, ultimately driving the motor with the desired frequency and amplitude. 1. Switching 2. Amplification 3.

How does a general-purpose inverter work?

The pulses are smoothed by the motor coil, and a sine wave current flows. As a result, the output from a general-purpose inverter cannot be used for equipment other than motors. V/f control is a method of controlling a motor by supplying a specific current to the coil to output a specific torque.

Update Information

- Inverter motor model and power

- Power frequency inverter connected to solar energy

- The photovoltaic inverter is first connected to the power supply

- Inverter that can increase motor power

- Communication base stations should be connected to several types of power

- Ethiopia house connected to outdoor power supply

- Finland s energy storage power station successfully connected to the grid

- Inverter real-time power and power ratio

- Manama Photovoltaic Power Generation Equipment Inverter

- CRRC 5MWh energy storage power station connected to the grid

- Croatia energy storage power station connected to substation

- Energy storage power station connected to new energy

- Solar panels connected to power storage container box

Solar Storage Container Market Growth

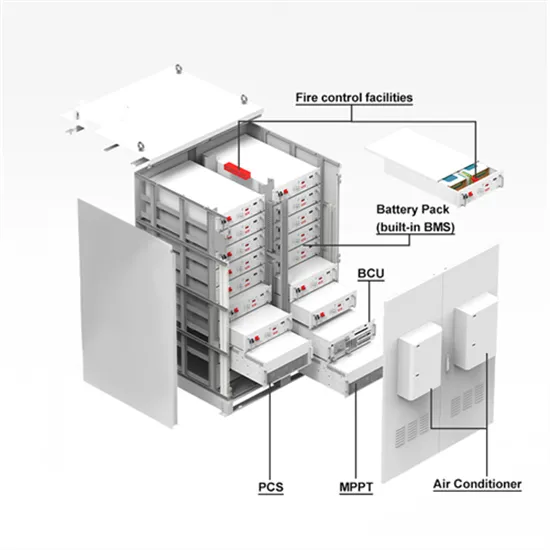

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

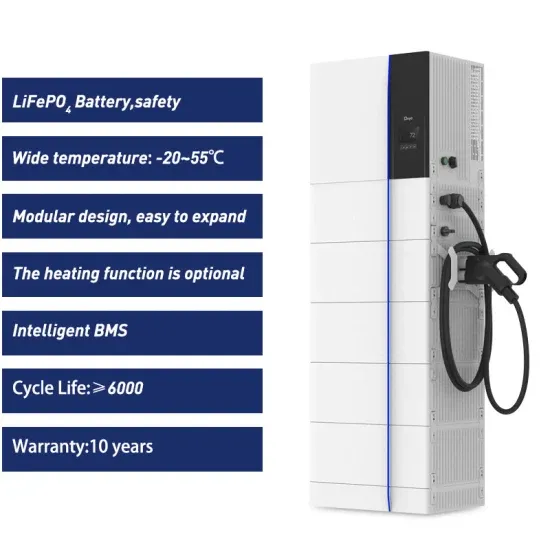

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.