What is an Inverter in Electric Vehicle? What

Jan 4, 2025 · 2. Higher power density: In the era of electric vehicles, the power of the motor is getting larger and larger, and at the same time, the peak power to

Inverter Parts Diagram and Function Overview

The diagram of an inverter plays a key role in identifying and understanding the function of each component within the system. Familiarity with these parts enables more accurate diagnostics,

Inverter Parts Diagram and Function Overview

Below is a breakdown of the most important parts that make up an inverter: Input DC Terminals: These terminals connect the inverter to the DC power source, such as a solar panel or battery.

The main components of inverters,converter tools

Apr 26, 2024 · Some of the main components of the inverter. The first to convert AC voltage into DC voltage; The second one converts this DC voltage into an AC voltage with variable

What are the Types and Main Components of

Aug 14, 2021 · The inverter is considered as the brain of the solar system. And although there are different types of the solar inverters, but they all have the

Power Inverters: What Are They & How Do They

Dec 17, 2019 · An inverter (or power inverter) is defined as a power electronics device that converts DC voltage into AC voltage. While DC power is common

The main components of inverters,converter tools

Apr 26, 2024 · The main components of inverters,converter toolsThe AC voltage becomes positive or negative rectified. In fact, what is being rectified is the current. In order to rectify the

Inverter PCB – an in-depth guide to the heart of

Feb 5, 2023 · What is PCB inverter? A Printed Circuit Board (PCB) inverter is an electronically powered device that converts direct current (DC) power into

What''s Inside Your Inverter? Main Components

Mar 20, 2025 · In this guide, we''ll break down the six key components that determine an inverter''s reliability and efficiency. We''ll also highlight top models

6 FAQs about [Inverter power components]

What are the components of a DC inverter?

DC Input: This is where the inverter connects to the DC power source. The power source could be solar panels, batteries, or other DC supplies. This component ensures that the inverter can receive electrical energy from these sources. Rectifier: In some inverters, a rectifier is essential, especially for converting AC to DC.

What is a DC inverter?

Inverter Definition: An inverter is defined as a power electronics device that converts DC voltage into AC voltage, crucial for household and industrial applications. Working Principle: Inverters use power electronics switches to mimic the AC current’s changing direction, providing stable AC output from a DC source.

What are the components of a solar inverter?

17. What Are The Key Components Of A Solar Inverter A solar inverter’s key components include the DC input source (solar panels), the power electronics circuit (typically with MOSFETs or IGBTs), the control circuit (managing voltage and current), and the transformer (for grid integration or voltage adjustment).

What are the parts of a power inverter?

It consists of the following two parts: Fuse: The fuse automatically opens if the current is too high, protecting the inverter from damage. DC disconnect switch: The DC disconnect is the safety valve of the system and ensures safe operation of the drive during maintenance. 2. MPPT Controller

What is a DC input in an inverter?

The DC input is responsible for providing a steady and consistent flow of energy, which the inverter will later convert into AC power. This component is vital in ensuring energy availability for the inverter’s operation. The power electronics circuit is a core component of an inverter.

What is a string inverter?

String inverters are commonly used in solar energy systems. They connect multiple solar panels in a series, forming a “string,” and convert the combined DC power into AC power. These inverters include components like MPPT (Maximum Power Point Tracking) systems, which optimize the energy harvest from solar panels.

Update Information

- Ups inverter power components

- Hargeisa Power Inverter Manufacturer

- Usp uninterruptible power supply to inverter

- Photovoltaic inverter power rises slowly

- Palestine 48v power frequency inverter

- What is the auxiliary power supply voltage of the inverter

- Off grid solar power inverter in Belarus

- Low frequency and low power inverter

- How big an inverter can a 12v20a battery power

- Ground power station inverter price

- What is the grid-connected power of the inverter

- Thailand Photovoltaic Power Inverter

- Democratic Republic of Congo off-grid power frequency 15kw inverter

Solar Storage Container Market Growth

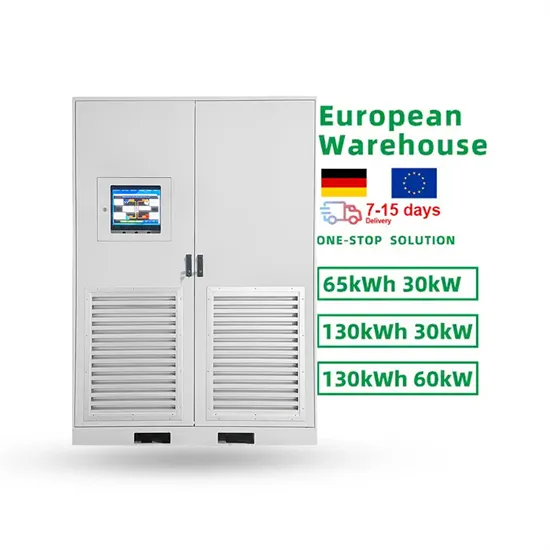

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.