Energy, economic and environmental analysis of a combined cooling

Sep 10, 2024 · Huge energy consumption of data centers has become a concern with the demand for greater computing power. Indirect liquid cooling is currently the main cooling method for the

Analysis of a Thermal Energy Storage Tank in a

Sep 16, 2020 · This study''s primary goal is to evaluate the performance of a large thermal energy storage tank installed in a Gas District Cooling (GDC) plant.

Evolution of Thermal Energy Storage for Cooling

First Generation of Thermal Energy Storage Cooling of commercial ofice buildings became widespread after World War II, and its availability contributed to the rapid population growth in

4E analysis and parameter study of a solar-thermochemical energy

Feb 1, 2024 · The combination of calcium looping and concentrating solar power (CSP) is a promising energy conversion technology that can greatly increase the share of solar energy

Parametric analysis and design optimisation of PCM thermal energy

Oct 1, 2020 · The paper presents a parametric analysis and design optimisation of an active PCM thermal energy storage system for space cooling of nearly zero-energ

Comprehensive review of energy storage systems

Jul 1, 2024 · The applications of energy storage systems have been reviewed in the last section of this paper including general applications, energy utility applications, renewable energy

Thermal Performance Study on a Sensible Cool Thermal Energy Storage

Jun 8, 2021 · Yan et al. [7] described an optimization method for the combined cool storage (CCS) system where the cool energy for the building cooling in summer was provided by the CWES

Design and Practice of District Cooling and Thermal

May 21, 2024 · 18 & 19 August 2014 District Cooling had been introduced and installed in Malaysia for the last 20 years and is being promoted as a way of addressing energy efficiency,

Performance optimization of phase change energy storage

May 30, 2024 · Combined cooling, heating, and power systems present a promising solution for enhancing energy efficiency, reducing costs, and lowering emissions. This study focuses on

Thermodynamic performance of air-cooled seasonal cold energy storage

Nov 1, 2024 · With the improvement in people''s living standards, there is a growing demand for cooling, making it urgent to develop a low-carbon and energy-efficient refrigeration system.

Efficient Cooling System Design for 5MWh BESS Containers:

Aug 10, 2024 · Discover the critical role of efficient cooling system design in 5MWh Battery Energy Storage System (BESS) containers. Learn how different liquid cooling unit selections impact

Influence of structural parameters on immersion cooling

Feb 15, 2025 · Single-phase immersion cooling has gained attention as a highly effective thermal management solution for battery energy storage systems, owing to its simple design and

Performance analysis of liquid cooling battery thermal

Nov 30, 2023 · In this paper, a parameter OTPEI was proposed to evaluate the cooling system''s performance for a variety of lithium-ion battery liquid cooling thermal management systems,

A state-of-the-art-review on phase change materials integrated cooling

Aug 1, 2020 · Multivariables involved in the review include thermo-physical, geometrical and operating parameters of PCMs. Multi-criteria employed in the review include heat transfer rate,

Lithium-ion battery thermal management via advanced cooling parameters

Jul 1, 2023 · In the present review, state of the art of advance cooling systems'' (such as air/liquid-based cooling, PCM, refrigeration, heat pipe and thermoelectric) parameters of Li-ion batteries

Study on uniform distribution of liquid cooling pipeline in

Mar 15, 2025 · Designing a liquid cooling system for a container battery energy storage system (BESS) is vital for maximizing capacity, prolonging the system''s lifespan, and improving its

125KW/233KWh Liquid-Cooling Energy Storage

Dec 30, 2024 · 5.5.3 Function Requirements Active power control function: the PCS energy storage device can control its active power output according to the instructions of the microgrid

2.5MW/5MWh Liquid-cooling Energy Storage System

Oct 29, 2024 · The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20''GP container, thermal management system, firefighting system, bus unit, power distribution unit,

Energy Storage System Cooling

May 5, 2025 · Energy storage systems (ESS) have the power to impart flexibility to the electric grid and offer a back-up power source. Energy storage systems are vital when municipalities

Energy storage technologies as techno-economic parameters

Nov 15, 2019 · In a multi-energy system, energy storage technologies typically exist in the form of electrochemical energy and thermal energy storage. Costs and technological limits of energy

Evaluation of a novel indirect liquid-cooling system for energy storage

Feb 15, 2025 · Higher cooling water flow velocity and lower cooling temperature are beneficial for the temperature uniformity of battery pack, with a cooling temperature controlled below 35 °C.

HANDBOOK FOR ENERGY STORAGE SYSTEMS

Singapore has limited renewable energy options, and solar remains Singapore''s most viable clean energy source. However, it is intermittent by nature and its output is affected by environmental

Research on systematic analysis and optimization method for ice storage

Jan 1, 2025 · Based on the field tests and analysis, typical issues were discovered leading to poor energy performance of ice-storage systems: 1) During workdays with large cooling demand,

A comprehensive investigation of phase change energy storage

Aug 1, 2025 · In the low-temperature field, LHTES technology is chiefly applied in building energy conservation, such as heat pump defrosting [16], [17], energy storage heat pumps [18], [19],

Technical report on best practices for energy storage

Jun 3, 2019 · Storage capacity: The storage method retained for solar heating and cooling systems ranges from very low energy storage capacity, for an off-grid system for example, to

Introduction to thermal energy storage systems

Jan 1, 2021 · Thermal energy storage (TES) systems can store heat or cold to be used later, at different conditions such as temperature, place, or power. TES systems are divided in three

Integrated cooling system with multiple operating modes for

Apr 15, 2025 · Integrated cooling system with multiple operating modes for temperature control of energy storage containers: Experimental insights into energy saving potential

2.5MW/5MWh Liquid-cooling Energy Storage System

Oct 29, 2024 · The energy storage system supports functions such as grid peak shaving, frequency regulation, backup power, valley filling, demand response, emergency power

Energy, exergy, and economic analysis of cold energy storage systems

Jul 1, 2025 · The effect of several parameters, including volumetric flow rate, temperature and humidity of the incoming air to the cold room evaporator coil and the cooling capacity of the

Modeling and optimization of a heating and cooling

Mar 15, 2025 · However, achieving global optimization for this system with complex physical features and energy interactions is still challenging in current literature, especially in a

The active thermal energy storage regulation of combined cooling

Oct 15, 2024 · Thermal energy storage has gradually become an important development direction for the active regulation of multi-energy compensated combined cooling, heating, and power

Smart design and control of thermal energy storage in low

Sep 1, 2022 · Thermal energy storage (TES) is recognized as a well-established technology added to the smart energy systems to support the immediate increase in energy demand,

Definitions of technical parameters for thermal energy

Sep 15, 2024 · 1. Introduction acterization and evaluation of thermal energy storage (TES) systems. Therefore, the main goal of IEA-ECES Annex 30 is to determine the suitability of a

6 FAQs about [Energy storage cooling system parameters]

What are the functions of the energy storage system?

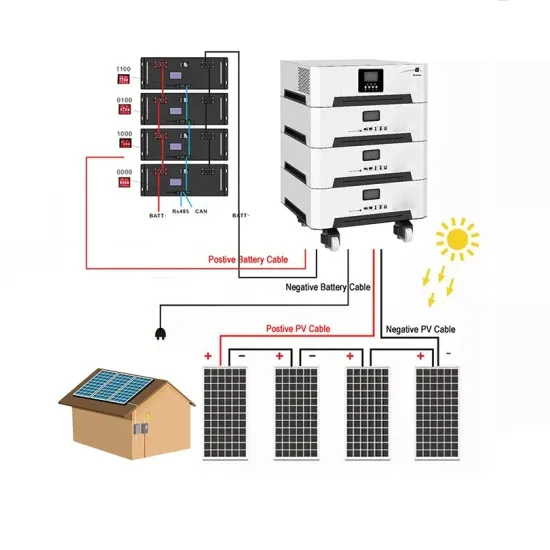

The energy storage system supports functions such as grid peak shaving, frequency regulation, backup power, valley filling, demand response, emergency power support, and reactive power compensation. The 2.5MW/5.016MWh battery compartment utilizes a battery cluster with a rated voltage of 1331.2V DC and a design of 0.5C charge-discharge rate.

How to choose an energy storage unit?

The choice of the unit should be based on the cooling and heating capacity parameters of the energy storage cabin, alongside considerations like installation, cost, and additional functionalities. 3.12.1.2 The unit must utilize a closed, circulating liquid cooling system.

How are energy storage batteries integrated in a non-walk-in container?

The energy storage batteries are integrated within a non-walk-in container, which ensures convenient onsite installation. The container includes: an energy storage lithium iron phosphate battery system, BMS system, power distribution system, firefighting system, DC bus system, thermal management system, and lighting system, among others.

How can a cold energy storage system be optimized?

The combination of these three evaluations - energy, exergy, and economic - can help in designing and developing optimal cold energy storage systems. These evaluations not only improve the technical performance of the system but can also lead to long-term reductions in costs and energy consumption. Fig. 2.

What is a liquid cooling thermal management system?

The liquid cooling thermal management system for the energy storage cabin includes liquid cooling units, liquid cooling pipes, and coolant. The unit achieves cooling or heating of the coolant through thermal exchange. The coolant transports heat via thermal exchange with the cooling plates and the liquid cooling units.

What is a cold energy storage system?

The cold energy storage system is an active method of reducing the energy consumption of air conditioning systems. This method shifts the peak electricity consumption from peak hours (high load) to off-peak hours (low load). Materials used for cold energy storage are known as PCM.

Update Information

- Internal electrical system of energy storage liquid cooling system

- Energy storage battery container parameters

- Austrian Liquid Cooling Energy Storage Container Company

- Liquid cooling and air cooling structure design of energy storage system

- Abkhazia Liquid Cooling Energy Storage Cabinet Company

- Swedish liquid cooling energy storage

- Photovoltaic power station energy storage 5MWH liquid cooling

- Key points of energy storage liquid cooling design

- Benefits of Liquid Cooling Energy Storage in Thailand

- Energy storage battery cooling device

- Danish liquid cooling energy storage project

- Energy storage battery module parameters

- Vaduz Liquid Cooling Energy Storage Cabinet Manufacturer

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.