What are the energy storage battery cooling

Jan 28, 2024 · 1. Effective cooling is essential for maintaining battery performance and longevity, 2. Different cooling techniques, such as air, liquid, and phase

Next-Gen Battery Cooling: Using AI, New Tech, and

Mar 21, 2025 · the thermal management systems in both EVs and stationary energy storage systems [17]. Additionally, advancements in energy storage technologies, such as the use of

Design and optimization of lithium-ion battery as an efficient energy

Nov 1, 2023 · Lithium-ion batteries (LIBs) have nowadays become outstanding rechargeable energy storage devices with rapidly expanding fields of applications due to

Channel structure design and optimization for immersion cooling

Jan 30, 2024 · The phenomenon of heat accumulation during the discharge process of lithium-ion batteries (LIBs) significantly impacts their performance, lifespan, and safety. A well-designed

Thermal Management Solutions for Battery

Apr 11, 2023 · Therefore, cooling systems serve as a critically important enabling technology for BESS, providing the thermal stability that is crucial for battery

A review of air-cooling battery thermal management systems for electric

Jul 31, 2021 · Due to its fast charging ability and long lifetime, it is usually adopted as the braking energy recover and storage device by most EV and HEV OEMs. Toyota Yaris and PSA

Thermal Management Technology of 1MWh BESS Energy Storage

Dec 27, 2024 · The 1MWh Battery Energy Storage System (BESS) is a crucial component in modern energy storage applications. As the capacity and power of BESS increase, thermal

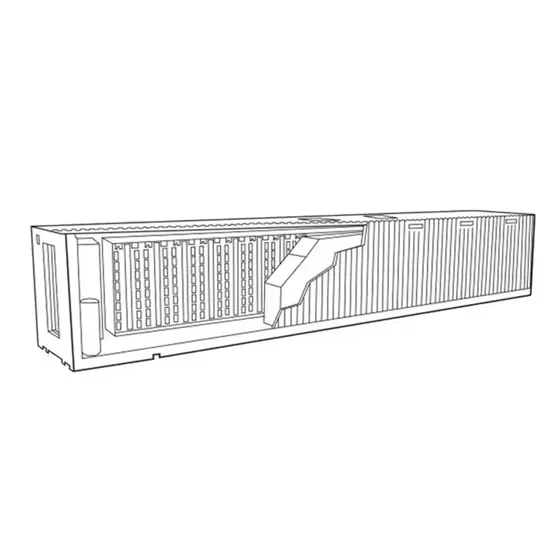

2.5MW/5MWh Liquid-cooling Energy Storage System

Oct 29, 2024 · 2 Energy Storage System Project 2.1 System Introduction The 2.5MW/5.016MWh battery compartment utilizes a battery cluster with a rated voltage of 1331.2V DC and a design

Advancements and challenges in battery thermal

Mar 1, 2025 · The contribution of this work lies in synthesizing recent advancements, identifying current challenges, and suggesting future research directions. Understanding and advancing

Energy, economic and environmental analysis of a combined cooling

Sep 10, 2024 · Indirect liquid cooling is currently the main cooling method for the cabinet power density of 20 to 50 kW per cabinet. An integrated energy storage batteries (ESB) and waste

Evaluation of a novel indirect liquid-cooling system for energy storage

Feb 15, 2025 · To achieve superior energy efficiency and temperature uniformity in cooling system for energy storage batteries, this paper proposes a novel indirect liquid-cooling system based

A comprehensive review of stationary energy storage devices

May 1, 2022 · Next to conventional batteries, flow batteries are another type of electrochemical energy storage devices playing a role in stationary energy storage applications [18, 19].

A review of battery energy storage systems and advanced battery

May 1, 2024 · This article provides an overview of the many electrochemical energy storage systems now in use, such as lithium-ion batteries, lead acid batteries, nickel-cadmium

Research progress on power battery cooling technology for

Feb 1, 2020 · In the charging and discharging process of new energy vehicles, how to maintain power battery within optimum operating temperature range, reduce the p

Exploration on the liquid-based energy storage battery

Dec 1, 2024 · However, the intermittent nature of these energy sources also poses a challenge to maintain the reliable operation of electricity grid [2]. In this context, battery energy storage

The reason why energy storage batteries always require

An increase in battery energy storage system (BESS) deployments reveal the importance of successful cooling design. Unique challenges of lithium-ion battery systems require careful

Advances in battery thermal management: Current

Aug 1, 2024 · Phase change materials have emerged as a promising passive cooling method in battery thermal management systems, offering unique benefits and potential for improving the

Energy Storage System Cooling

May 5, 2025 · Battery back-up systems must be efficiently and effectively cooled to ensure proper operation. Heat can degrade the performance, safety and operating life of battery back-up

6 FAQs about [Energy storage battery cooling device]

Can a battery energy storage system fit a closed-loop air conditioner?

A leading manufacturer of battery energy storage systems contacted Kooltronic for a thermal management solution to fit its rechargeable power system. Working collaboratively with the manufacturer, Kooltronic engineers modified a closed-loop air conditioner to fit the enclosure, cool the battery compartment, and maximize system reliability.

What is a battery energy storage system?

Battery energy storage systems (BESS) ensure a steady supply of lower-cost power for commercial and residential needs, decrease our collective dependency on fossil fuels, and reduce carbon emissions for a cleaner environment.

What is a thermal management system for electric vehicle batteries?

Thermal management system for electric vehicle batteries that allows individual cooling or heating of different zones within the battery to optimize performance and lifespan. The system uses multiple distinct circuits, each associated with a cooling zone, with independent flow control valves.

How does a battery cooling system work?

The system uses a network of flexible tubes connecting intake and exhaust manifolds with channels tuned for even fluid flow distribution. It allows direct contact cooling/heating of individual battery cells by conforming tubes passing between them. The system connects to a pump and heat exchanger for circulating fluid through the pack.

Do battery back-up systems need to be cooled?

Battery back-up systems must be efficiently and effectively cooled to ensure proper operation. Heat can degrade the performance, safety and operating life of battery back-up systems. Traditionally, battery back-up systems used custom compressor-based air conditioners.

Why is cooling a battery important?

Higher C-Rate, more frequent cycling causes increased heat dissipation therefore an effective cooling concept is mandatory. Thermal stability is crucial for battery performance and durability - battery degradation and damage will bereduced and downtime minimized. Battery safety must be prioritized.

Update Information

- Energy storage cabinet battery 5MWH liquid cooling production

- Battery Phase Change Energy Storage Cooling Disadvantages

- Energy Storage Water Cooling Battery Cabinet Base Station

- Energy Storage Battery Container Liquid Cooling System Manufacturers Ranking

- Liquid Cooling Energy Storage Battery Station 20wmh Price

- Which brand of energy storage lithium battery pack is good

- Tuvalu energy storage lithium battery pack customization

- Managua Valley Electric Energy Storage Device Supplier

- Democratic Republic of Congo Commercial Energy Storage Device Manufacturer

- Yerevan battery energy storage power station approved

- Buenos Aires Immersion Liquid Cooling Energy Storage

- Battery energy storage system of communication base station disturbs residents

- Copenhagen energy storage battery brand ranking

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

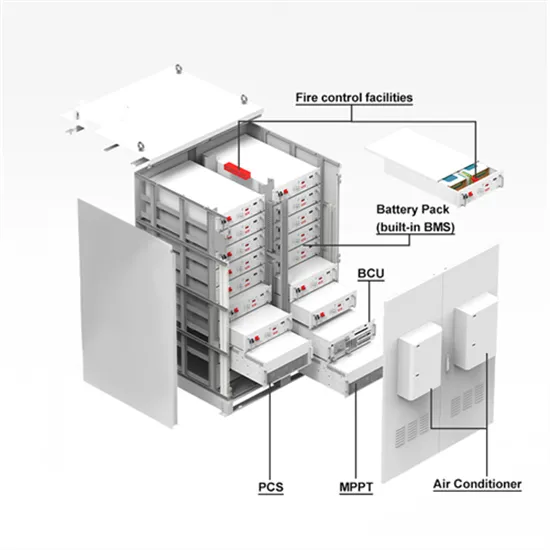

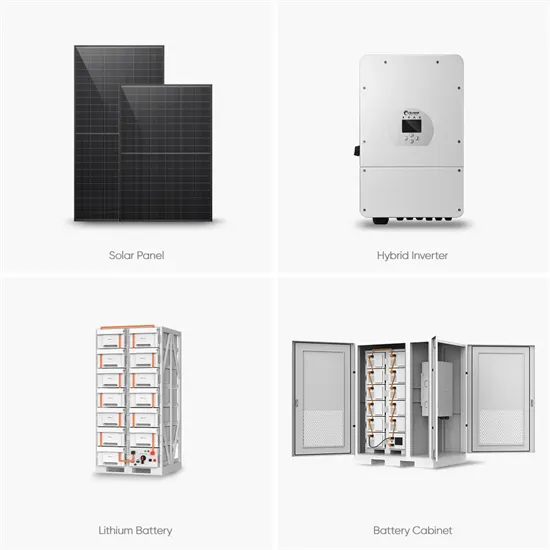

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.