Evaluation of a novel indirect liquid-cooling system for energy storage

Feb 15, 2025 · Higher cooling water flow velocity and lower cooling temperature are beneficial for the temperature uniformity of battery pack, with a cooling temperature controlled below 35 °C.

WHAT IS ENERGY STORAGE LIQUID COOLING SYSTEM

What does the liquid cooling energy storage cabinet structure design service include To develop a liquid cooling system for energy storage, you need to follow a comprehensive process that

Research progress in liquid cooling technologies to enhance

Aug 29, 2023 · In terms of liquid-cooled hybrid systems, the phase change materials (PCMs) and liquid-cooled hybrid thermal management systems with a simple structure, a good cooling

Two-phase immersion liquid cooling system for 4680 Li-ion

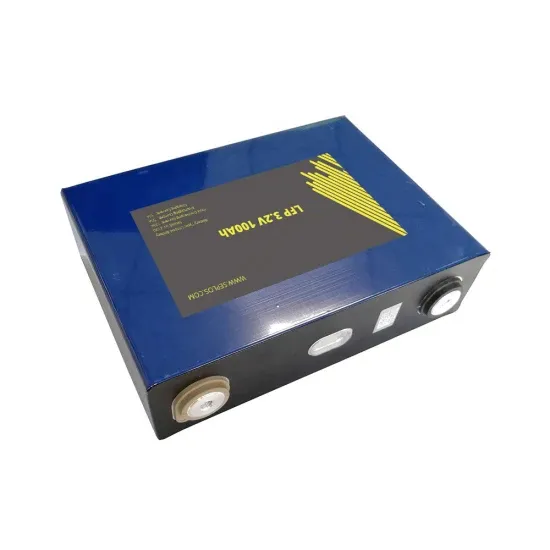

Sep 10, 2024 · Lithium-ion batteries are widely adopted as an energy storage solution for both pure electric vehicles and hybrid electric vehicles due to their exceptional energy and power

Research on Optimization of Thermal Management System for Liquid

Apr 19, 2025 · This paper focuses on the optimization of the cooling performance of liquid-cooling systems for large-capacity energy storage battery modules. Combining simulation analysis

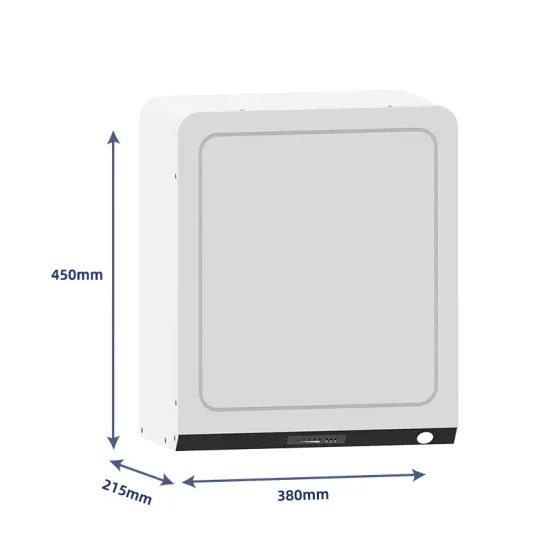

EGS215 Liquid Cooling Battery Energy Storage System

Feb 11, 2025 · Energy storage ba ery cabinet is a high-voltage energy storage equipment, belongs to the dangerous goods, non-professionals and improper opera on and use may

A review on the liquid cooling thermal management system

Dec 1, 2024 · Therefore, it is necessary to explore a multi-objective optimization system to design liquid plate BTMS and use a unified evaluation system to assess the capability of LCP cooling

Liquid Cooling Solutions for Energy Storage Systems.

May 2, 2025 · Our innovative liquid cooling solutions offer numerous advantages, including efi cient heat dissipation for longer battery life, even temperature distribution for optimal

A review on cool thermal storage technologies and operating strategies

Jan 1, 2012 · The thermal energy storage (TES) system for building cooling applications is a promising technology that is continuously improving. The TES system can balance the energy

Evolution of Thermal Energy Storage for Cooling

First Generation of Thermal Energy Storage Cooling of commercial ofice buildings became widespread after World War II, and its availability contributed to the rapid population growth in

LIQUID COOLING SOLUTIONS For Battery Energy

Aug 3, 2022 · For Battery Energy Storage Systems Are you designing or operating networks and systems for the Energy industry? If so, consider building thermal management solutions into

Advances in battery thermal management: Current

Aug 1, 2024 · In the present era of sustainable energy evolution, battery thermal energy storage has emerged as one of the most popular areas. A clean energy alternative to conventional

Thermal management performance and optimization of a hybrid system

Jul 15, 2025 · Modeling and analysis of liquid-cooling thermal management of an in-house developed 100 kW/500 kWh energy storage container consisting of lithium-ion batteries retired

Review on operation control of cold thermal energy storage in cooling

Jun 1, 2025 · Cold storage technology is useful to alleviate the mismatch between the cold energy demand and supply. The integration of cold energy storage in cooling system is an effective

High-uniformity liquid-cooling network designing approach for energy

Nov 1, 2024 · Electrochemical battery energy storage stations have been widely used in power grid systems and other fields. Controlling the temperature of numerous batteries in the energy

Thermal Management Technology of 1MWh BESS Energy Storage System

Dec 27, 2024 · The 1MWh Battery Energy Storage System (BESS) is a crucial component in modern energy storage applications. As the capacity and power of BESS increase, thermal

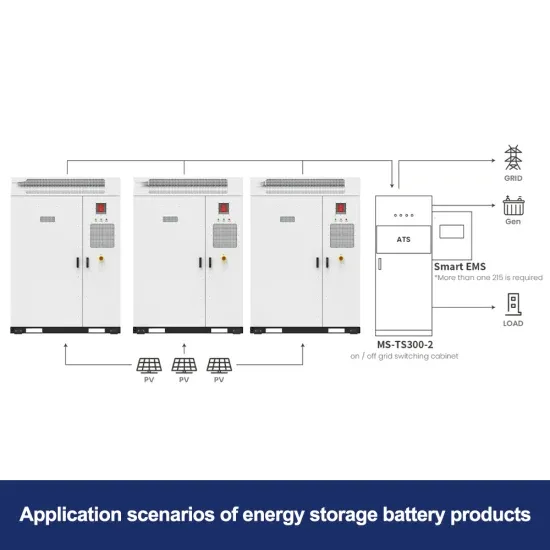

2.5MW/5MWh Liquid-cooling Energy Storage System

Oct 29, 2024 · The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20''GP container, thermal management system, firefighting system, bus unit, power distribution unit,

5.01MWh User Manual for liquid-cooled ESS

Jan 9, 2025 · The energy storage system of this product adopts integrated design, which integrates the energy storage battery cluster and battery management system into a 20-foot

Optimized thermal management of a battery energy-storage system

Jan 1, 2023 · Increased air residence time improves the uniformity of air distribution. Inspired by the ventilation system of data centers, we demonstrated a solution to improve the airflow

Engineering Design of Liquid Cooling Systems in

Jul 3, 2025 · A well-integrated Liquid Cooled Energy Storage Cabinet doesn''t just run cooler—it runs smarter and lasts longer. In practical applications like

Liquid Cooling Energy Storage System Module Design

With the energy density increase of energy storage systems (ESSs), air cooling, as a traditional cooling method, limps along due to low efficiency in heat dissipation and inability in

Integrated cooling system with multiple operating modes for

Apr 15, 2025 · Aiming at the problem of insufficient energy saving potential of the existing energy storage liquid cooled air conditioning system, this paper integrates vapor compression

Energy Storage System Cooling

May 5, 2025 · Energy storage systems (ESS) have the power to impart flexibility to the electric grid and offer a back-up power source. Energy storage systems are vital when municipalities

Exploration on the liquid-based energy storage battery system

Dec 1, 2024 · Lithium-ion batteries are increasingly employed for energy storage systems, yet their applications still face thermal instability and safety issues. This study aims to develop an

Research on the optimization control strategy of a battery

Feb 28, 2025 · The widespread use of lithium-ion batteries in electric vehicles and energy storage systems necessitates effective Battery Thermal Management Systems (BTMS) to mitigate

6 FAQs about [Internal electrical system of energy storage liquid cooling system]

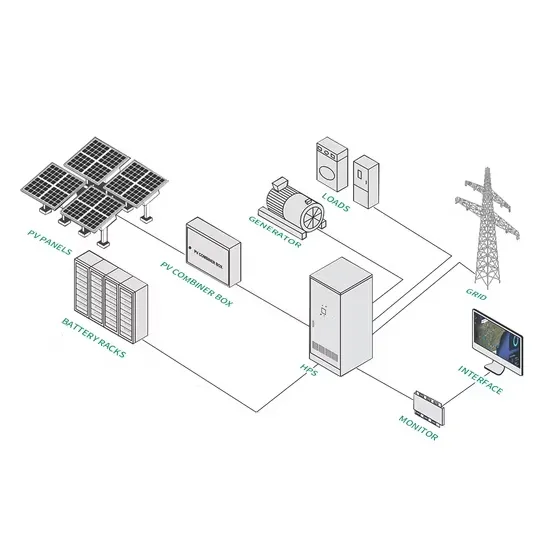

What is a 5MWh liquid-cooling energy storage system?

The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20’GP container, thermal management system, firefighting system, bus unit, power distribution unit, wiring harness, and more. And, the container offers a protective capability and serves as a transportable workspace for equipment operation.

What is a liquid cooling unit?

The product installs a liquid-cooling unit for thermal management of energy storage battery system. It effectively dissipates excess heat in high-temperature environments while in low temperatures, it preheats the equipment. Such measures ensure that the equipment within the cabin maintains its lifespan.

What is a liquid cooling thermal management system?

The liquid cooling thermal management system for the energy storage cabin includes liquid cooling units, liquid cooling pipes, and coolant. The unit achieves cooling or heating of the coolant through thermal exchange. The coolant transports heat via thermal exchange with the cooling plates and the liquid cooling units.

How are energy storage batteries integrated in a non-walk-in container?

The energy storage batteries are integrated within a non-walk-in container, which ensures convenient onsite installation. The container includes: an energy storage lithium iron phosphate battery system, BMS system, power distribution system, firefighting system, DC bus system, thermal management system, and lighting system, among others.

What is a liquid cooling system?

This project’s liquid cooling system consists of primary, secondary, and tertiary pipelines, constructed by using factory prefabrication and on-site assembly within the cabin. The primary liquid cooling pipes utilize 304 stainless steel, whereas the secondary and tertiary pipes are made from PA12 nylon tubing.

How does a liquid cooling unit work?

3.12.1.3 The design of the liquid cooling unit must align with the cabin structure, adequately addressing dust prevention needed in the operating environment. The liquid cooling pipeline operates in a closed loop. The coolant, propelled by a pump, circulates through the cold plate, exchanging heat with the batteries, which raises its temperature.

Update Information

- Liquid Cooling Energy Storage Cabinet Brand Ranking

- Which company in Hanoi does containerized liquid cooling energy storage

- Key points of energy storage liquid cooling design

- Energy storage liquid cooling system power

- Buenos Aires Immersion Liquid Cooling Energy Storage

- Seychelles Liquid Cooling Energy Storage

- Gabon Liquid Cooling Energy Storage Operation

- Outdoor Energy Storage Liquid Cooling Battery Cabinet

- Liquid Cooling Energy Storage Container Base Station

- Liquid Cooling Energy Storage Battery Station 20wmh Price

- Abkhazia Liquid Cooling Energy Storage Cabinet Company

- Benefits of Liquid Cooling Energy Storage in Thailand

- Sana Liquid Cooling Energy Storage

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.