High-capacity semi-organic polymer batteries: From monomer to battery

Feb 1, 2023 · Since aqueous electrolytes are cost-efficient, rather non-toxic and available in large quantities, they are in particular promising for energy storage devices. Together with the zinc

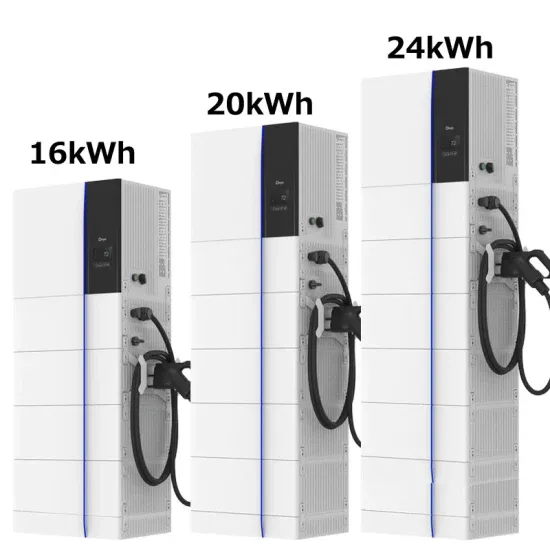

Lithium battery energy storage monomer capacity

Second,lifetime comparisons of lithium-ion batteries are widely discussed in the literature,(3-8) but these comparisons are especially challenging due to the high sensitivity of lithium-ion battery

Designing polymers for advanced battery chemistries

Apr 3, 2019 · In this Review, we discuss core polymer science principles that are used to facilitate progress in battery materials development. Specifically, we discuss the design of polymeric

Graphene footprints in energy storage systems—An overview

Dec 1, 2023 · The state-of-the-art overview principally addresses fundamentals of graphene and derived nanocomposites. Subsequently, energy or charge storage applications of graphene

High-capacity semi-organic polymer batteries: From monomer to battery

Feb 1, 2023 · In terms of device fabrication, we focused on a semi-organic system using zinc as anode material, which is particularly attractive due to high theoretical battery

Ev car battery pack,ev car battery technology

Dec 8, 2024 · I. Lithium Monomer Battery 1. Composition and classification Monomer (Cell), also known as the core, is the smallest unit of chemical energy into electrical energy, monomer

Automobile energy storage device monomer

The most dominant type of secondary batteries for modern devices is the lithium-ion battery. Lithium-ion batteries possess high energy densities, good rate capabilities, and a long cycle

High-performance fibre battery with polymer gel electrolyte

Apr 24, 2024 · A fibre lithium-ion battery that can potentially be woven into textiles shows enhanced battery performance and safety compared with liquid electrolytes.

Bioresource-derived polymer composites for energy storage applications

Oct 1, 2021 · Generally, batteries provide better storage of energy density while supercapacitors has greater power density. In recent years, the need for more environmentally safe materials

Recent progress in environment-adaptable hydrogel

Dec 10, 2023 · This review provides recent progress of environment-adaptable hydrogel electrolytes for flexible energy storage devices, ranging from environment-adaptable hydrogel

Energy storage lithium battery large monomer

Lithium-ion batteries (LIBs) with features of lightweight, high energy density, and long life have been widely applied as the power source for electric vehicles, portable electronic devices, as

Review of battery-supercapacitor hybrid energy storage

Dec 1, 2024 · The potential of using battery-supercapacitor hybrid systems. Currently, the term battery-supercapacitor associated with hybrid energy storage systems (HESS) for electric

Ev car battery pack,ev car battery technology

Dec 8, 2024 · When the battery is charged, lithium ions are embedded between the graphite layers to form a lithium-carbon interlayer compound (LixC6), which enables the storage of

Automobile energy storage device monomer

The power flow connection between regular hybrid vehicles with power batteries and ICEV is bi-directional, whereas the energy storage device in the electric vehicle can re-transmit the

What Is a Storage Battery Monolith? (And Why It''s the

Let''s Start with the Basics: What''s a Battery Monolith? Picture a storage battery monomer as the LEGO brick of energy storage – it''s the smallest, most fundamental unit that makes big battery

Advancements in energy storage: a review of batteries and

Aug 9, 2025 · Energy storage technologies are fundamental to overcoming global energy challenges, particularly with the increasing demand for clean and efficient power solutions.

What are the energy storage battery monomers? | NenPower

Jan 6, 2024 · 1. Energy storage battery monomers play a vital role in the overall efficiency and performance of storage systems. 2. These components include polymer chemistry, molecular

6 FAQs about [Battery energy storage device monomer]

Are lithium-ion batteries a promising electrochemical energy storage device?

Batteries (in particular, lithium-ion batteries), supercapacitors, and battery–supercapacitor hybrid devices are promising electrochemical energy storage devices. This review highlights recent progress in the development of lithium-ion batteries, supercapacitors, and battery–supercapacitor hybrid devices.

What are electrochemical energy storage devices?

Electrochemical Energy Storage Devices─Batteries, Supercapacitors, and Battery–Supercapacitor Hybrid Devices Great energy consumption by the rapidly growing population has demanded the development of electrochemical energy storage devices with high power density, high energy density, and long cycle stability.

Are polymer materials a key component of electrochemical energy storage devices?

Nature Reviews Materials 4, 312–330 (2019) Cite this article Electrochemical energy storage devices are becoming increasingly important to our global society, and polymer materials are key components of these devices.

Can biopolymer membranes be used for lithium ion batteries?

After integrating the biopolymer membrane into a magnesium battery, they reached an electrochemical stability of 3.58 V, while the open circuit of the battery was found to be 1.9 V. Finally, Yu et al. utilized cellulose waste corn straw to develop carbon nanospheres as the anode material for lithium-ion batteries .

Why are polymers important in battery engineering?

Polymers are ubiquitous in batteries as binders, separators, electrolytes and electrode coatings. In this Review, we discuss the principles underlying the design of polymers with advanced functionalities to enable progress in battery engineering, with a specific focus on silicon, lithium-metal and sulfur battery chemistries.

Are new battery chemistries a promising path to high-performance energy storage?

Overall, new battery chemistries offer promising paths towards high-performance energy storage (Fig. 2d) for improved sustainability, and there is a significant opportunity for innovation in polymer science and engineering to help solve longstanding problems and enable the development of these devices.

Update Information

- Energy storage battery cooling device

- Energy storage battery compartment ventilation device

- Energy Storage Battery Cabinet Standard

- South Korea s cascade battery energy storage power station

- Is the battery in the energy storage cabinet very powerful

- New lithium battery energy storage cabinet equipment

- How much does Kosovo energy storage battery cost

- How much current does the energy storage cabinet battery output

- China aids in building battery energy storage system for communication base stations

- Energy Storage Cabinet Battery Industry Scale Analysis Report

- 12v400ah energy storage battery price

- What is the efficiency of the energy storage device

- Honiara communication energy storage battery manufacturer

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.