Ventilation and Thermal Management of Stationary

Jan 10, 2023 · The purpose of the document is to build a bridge between the battery system designer and ventilation system designer. As such, it provides information on battery

Battery Cabinet Ventilation Design | We Group E-Site

Feb 27, 2023 · As lithium-ion batteries dominate energy storage, battery cabinet ventilation design has emerged as a critical engineering challenge. Did you know a 10°C temperature rise above

Inside the energy storage battery compartment

An electric battery is an energy storage device comprising one or more electrochemical cells. These cells have external connections used to power electrical devices. When providing

Battery Room Ventilation Code Requirements

Dec 13, 2022 · Battery Room Ventilation Code Requirements Battery room ventilation codes and standards protect workers by limiting the accumulation of hydrogen in the battery room.

Battery Room Ventilation and Safety

Mar 15, 2023 · Calculate the ventilation rate for a battery room consisting of 182-cell battery and 3 battery banks. Assume the battery room has dimensions of 20'' (l) x 15'' (w) x 10'' (h).

Lithium-ion energy storage battery explosion incidents

Sep 1, 2021 · Utility-scale lithium-ion energy storage batteries are being installed at an accelerating rate in many parts of the world. Some of these batteries have experienced

What are the ventilation requirements for energy

How much ventilation does a battery room need? ventilation rate required is 1.0 cfm/sq-ft.An alternative variation of continuous ventilation in air conditioned battery room spaces is to

Simulation analysis and optimization of containerized energy storage

Sep 10, 2024 · The air-cooling system is of great significance in the battery thermal management system because of its simple structure and low cost. This study analyses the thermal

BATTERY COMPARTMENT VENTILATION SYSTEM

FAQS about Battery compartment corrosion How does battery corrosion affect the performance of electronic devices? Battery corrosion is a common issue that affects the performance and

Ventilation condition effects on heat dissipation of the

Nov 1, 2024 · Therefore, a lithium-ion battery energy storage cabin requires an efficient ventilation condition to ensure fire safety. This work investigates the effects of ventilation mode,

Inside the energy storage battery compartment | Solar

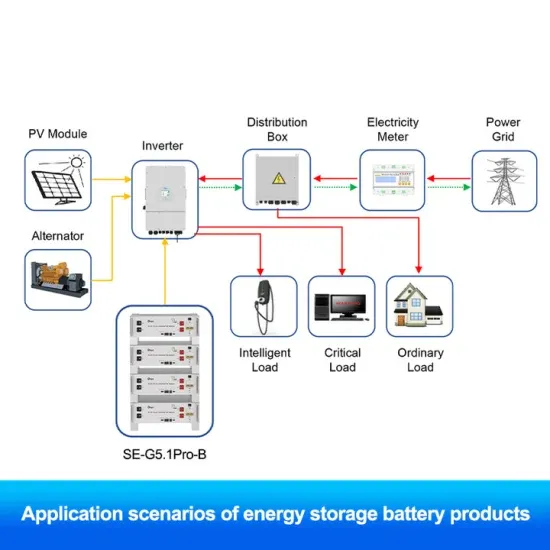

Energy Storage System | Key Technologies Explained Learn about energy storage & its technologies, discover their diverse benefits and vital role in shaping a sustainable energy

Energy storage battery compartment design

It can be seen from Figure 1 that in the energy storage system, the prefabricated cabin is the carrier of the energy storage devices, the most basic component of the energy storage

ENERGY STORAGE COMPARTMENT VENTILATION

container fan improve air ventilation? The existing thermal runaway and barrel effect of energy storage container with multiple battery pac s have become a hot topic of research. This paper

Clause 10.3 Energy Storage Systems

b. All Energy Storage System installations shall be located at the same storey as the fire engine accessway/ fire engine access road. c. The allowable Maximum Stored Energy for the various

Battery venting

5 days ago · Battery venting is a critical safety feature in batteries that prevents the build-up of pressure and gas. Different types of batteries, like lead-acid and lithium-ion, have unique

A thermal management system for an energy storage battery

May 1, 2023 · The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research. This paper innovatively proposes

6 FAQs about [Energy storage battery compartment ventilation device]

Can a battery container fan improve air ventilation?

The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research. This paper innovatively proposes an optimized system for the development of a healthy air ventilation by changing the working direction of the battery container fan to solve the above problems.

Why is battery venting important for energy storage systems?

Battery venting is crucial for energy storage systems due to several reasons: In energy storage systems, proper battery venting is critical for safety. Energy storage installations often involve a large number of interconnected batteries, and any build-up of gases within these batteries can pose a significant safety hazard.

Does a battery room need a ventilation system?

The ventilation system for the battery room shall be separate from ventilation systems for other spaces. Air recirculation in the battery room is prohibited. Exhaust air through a dedicated exhaust duct system if the battery room is not located on an outside wall.

What is thermal management of batteries in stationary installations?

thermal management of batteries in stationary installations. The purpose of the document is to build a bridge betwe the battery system designer and ventilation system designer. As such, it provides information on battery performance characteristics that are influenced by th

Can ASHRAE develop a joint standard on battery room ventilation?

of developing a joint standard on battery room ventilation. For ASHRAE the goal was to reduce the energy consumption that results from traditional battery room ventilation systems where al

Why does a battery need to be ventilated?

Ventilation is essential to allow for the safe release of gases that may accumulate within the battery during the charging and discharging processes. For lead-acid batteries, adequate ventilation is crucial to prevent the build-up of hydrogen and oxygen gases, which are byproducts of the battery’s operation.

Update Information

- Is the current in the energy storage battery compartment DC or AC

- Energy storage battery compartment composition

- Battery compartment of lithium-ion battery energy storage power station

- Battery energy storage device monomer

- Energy storage battery cabinet fire protection acceptance specification

- Energy storage photovoltaic lithium battery company

- Huawei Energy Storage Battery

- Ultra-large battery sodium-ion energy storage cabinet

- North Korea portable energy storage battery enterprise

- Israeli aluminum acid energy storage battery brand

- Abkhazia high voltage pulse energy storage device

- Democratic Republic of Congo Commercial Energy Storage Device Manufacturer

- Chisinau local energy storage battery model

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.