How to cut the edges of photovoltaic glass panels

How to cut the edges of photovoltaic glass panels Working of Bifacial Solar Panels. A photo voltaic cell is placed inside the module and has glass on both the rear side and front sides.

Photovoltaic glass edge defect detection based on improved

Apr 15, 2024 · 标题 Photovoltaic glass edge defect detection based on improved SqueezeNet 基于改进SqueezeNet的光伏玻璃边缘缺陷检测 相关领域 光伏系统 边缘检测 GSM演进的增强数

Experimental repair technique for glass defects of glass-glass

Aug 1, 2023 · A failure of growing importance is the defect in the glass layer (s) of glass-glass PV modules. In this research, an experimental glass repair technique for glass-glass PV modules

Laser-Welded Edge Seals for Glass/Glass PV

Aug 13, 2025 · DuraMAT will explore the viability of glass-to-glass laser welding for hermetically sealed photovoltaic (PV) modules. Glass samples will be laser

Photovoltaic glass edge defect detection based on

Mar 19, 2024 · The experimental results show that the average leakage rate of the photovoltaic glass edge defect detection method proposed in this paper is 0.0064%, the misdetection

A review on photovoltaic combined vacuum glazing: Recent

May 1, 2023 · A solder glass edge sealing material with a 500 °C melting point was used to create that glazing with a 1 m by 1 m glazing size, the center of glazing U-value was reported to be

CEA recommendations for mitigating glass breakage – pv

Jul 28, 2025 · Include glass edge trimming and grinding as well as framing inspections in your quality assurance programs, as small impurities in frame parts can be the death of glass edges.

What is Photovoltaic Glass (or solar pv glass)?_

Jul 23, 2025 · 1.1.7 Summary The factors determining the performance of crystalline silicon solar photovoltaic cells are various factors related to the conversion efficiency of light energy. The

Advances in Antireflection Coatings on Photovoltaic Glass

Antireflection coatings (ARCs) can effectively suppress the loss caused by the interfacial reflection. To some extent, it is necessary to fabricate ARCs on the surface of PV glass in PV

Application of transparent self-cleaning coating for photovoltaic

Jun 1, 2022 · This review article focuses on the recent development of transparent self-cleaning coating based on the glass panel application especially for the photovoltaic (PV) panel

How to cut solar photovoltaic glass | NenPower

Jul 9, 2024 · Handling cut photovoltaic glass safely involves implementing a series of precautions to mitigate risks associated with sharp edges and glass fragments. Wearing protective gear is

Photovoltaic glass edge defect detection based on improved

Jan 10, 2024 · In order to solve the problems of low efficiency, susceptibility to interference by human factors, and low detection accuracy during the detection of photovoltaic glass edge

Evaluation and Modeling of Edge-Seal Materials for

Sep 30, 2013 · We demonstrate how a thin film of Ca deposited on a glass substrate laminated to another piece of glass can be used to evaluate edge seal materials. This method is

Double-glass PV modules with silicone encapsulation

May 21, 2024 · In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is

Photovoltaic Glass Treatments: Clarifying Terminologies and

Different treatments can enhance the mechanical performance of glass, particularly in terms of static load resistance (measured in Pascals) and hail resistance (as per IEC 61215,

Metal Bond Diamond Grinding Wheel for Solar Photovoltaic Glass

Jan 10, 2025 · Solar Photovoltaic Glass Diamond Grinding Wheel<br> Abrasive: Diamond<br> Bond:bronze/metal<br> Application: Round edge glass edging machines<br>

Assessment of long term reliability of photovoltaic glass–glass modules

Apr 1, 2015 · Quantifying the reliability of photovoltaic (PV) modules is essential for consistent electrical performance and achieving long operational lifetimes.

Jie, Xiong最新论文:基于改进挤压网的光伏玻璃边缘缺陷检测

Jan 22, 2024 · 研究内容 本文提出了一种基于机器视觉技术的光伏玻璃边缘缺陷自动检测方法。首先,设计了一种机器视觉缺陷检测系统,包括多个光源的高对比度成像方案和高稳定性的自动

光伏玻璃表面微织构柱体抗颗粒冲击性能研究

Abstract: To investigate the effects of the micro-textures and the impact mode of the particles on the damage of the surface micro-textures of the photovoltaic glass, a simulation model is

6 FAQs about [Photovoltaic glass edge rubbing]

How do glass defects affect a PV system?

Glass defects impact the economic performance of a PV system in multiple ways. The most obvious effect is the potential (in)direct performance loss of PV modules, which results in reduced economic revenues. Secondly, PV modules that suffer from glass defects may no longer meet safety requirements, therefore these modules are replaced.

Are glass-glass PV modules a problem?

Unfortunately, glass-glass PV modules are, similar to regular PV modules, subject to early life failures. A failure of growing concern are defects in the glass layer (s) of PV modules. The scale of decommissioned PV modules with glass defects will increase with the development of solar PV energy [ 7 ].

Can edge seal materials be used in photovoltaic applications?

Here, using a Ca film deposited on a glass substrate, we demonstrate the evaluation of edge seal materials in a manner that effectively duplicates their use in a photovoltaic application and compare the results with standard methods for measuring water vapor transport.

Does weathering damage glass PV modules?

In glass-glass PV modules the interlayer is often Polyolefin Elastomer (POE) encapsulant. Subsequent weathering of the encapsulant, such as the ingress of moisture, may decrease the strength of defected glass PV modules. This will reduce the lifetime of the module and cause corrosion of internal components [ 20 ].

Can PV modules survive a glass defect?

However, glass defects do not directly imply that PV modules endure internal damage nor that PV modules cannot continue to operate with minimal microcracks. Thus far, glass defects have been regarded as a failure beyond repair and no noticeable attempt has been made to develop reparation methods.

How thick is a glass-glass PV module?

2.2. Glass characteristics Glass-glass PV modules generally use 2–3 mm thick glass layers, since thicker glass layers negatively impact the module's weight and costs, while trends are to reduce glass thickness to below 2 mm [ 10 ].

Update Information

- Single-glass photovoltaic panel glass thickness

- Grenada double glass photovoltaic modules

- Advantages of photovoltaic glass panels

- Personal work in photovoltaic glass

- Tuvalu photovoltaic conductive glass manufacturer

- Photovoltaic glass separation and sorting equipment

- Slovenia non-standard photovoltaic glass cells

- Huawei photovoltaic glass name

- Rooftop photovoltaic component glass

- Photovoltaic Glass Greenhouse Ecological Park

- Silicon-based photovoltaic glass manufacturers

- Photovoltaic 2 5mm glass production

- Is photovoltaic glass acid

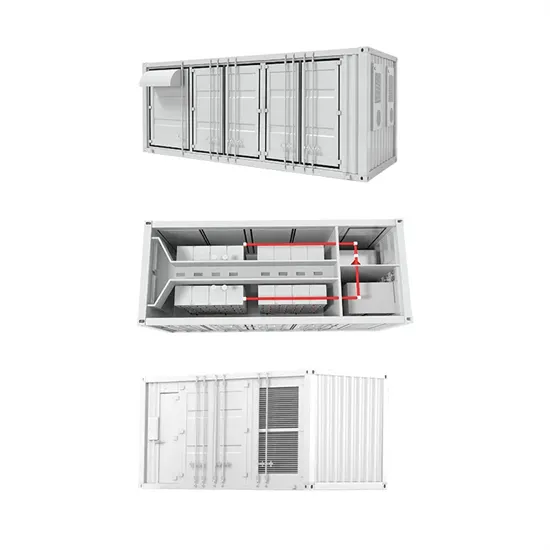

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.