The Performance of Double Glass Photovoltaic Modules

Sep 1, 2017 · In recent years, with the rapid development of the photovoltaic industry, double glass module as a high reliability and high weather resistance product is favored by many PV

Experimental investigation on the combustion performance of single

Jun 15, 2025 · Under similar glass material conditions, double-glazed modules exhibited superior combustion performance compared to their single-glass counterparts. Therefore, locations

Photovoltaic panel size specifications thickness

Photovoltaic panel size specifications thickness 60-Cell Solar Panels. The typical size of a solar panel, such as the 60-cell variant, is designed in a 6×10 configuration and has

How thick is the photovoltaic panel glass

thickness of PV glass plays a crucial role in its structural integrity and performance: Range: Common thicknesses range from 3.2mm to 6mmfor individual glass panes. Configurations:

3.2mm Glass Thickness Single Glass Solar Photovoltaic

Product descriptions from the supplier Product Description Specification Component dimensions (length * width * height) 2172x1303x 33 mm Solar cell N-type monocrystalline silicon Quantity

Solar Panel Thickness: What You Need to Know

Apr 18, 2025 · Learn how solar panel thickness impacts performance, durability, and cost. This article offers insights to help you make the best purchase decision.

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · This chapter examines the fundamental role of glass materials in photovoltaic (PV) technologies, emphasizing their structural, optical, and spectral conversion properties that

How thick is the glass used in photovoltaic brackets

May 27, 2024 · What is the thickness of PV glass? s range from 3.2mm to 6mmfor individual glass panes. Configurations: Total thickness varies based on the configuration (single

Single-glass versus double-glass: a deep dive into module

Oct 2, 2024 · For instance, the transition from 3.2mm to 2.8mm for single-glass modules and 2mm for double-glass modules, and even to 1.6mm, necessitates a careful consideration of the

What are the advantages of dual-glass Dualsun modules?

Aug 18, 2025 · Two types of photovoltaic module structures coexist: Glass-polymer film (also called glass-backsheet) type modules. They are made of glass on the front side and polymer

What is the appropriate weight of photovoltaic panel glass

Weight -- Glass must be of a certain weight for solar panels. The industry standard weight for a 3.2 mm thick solar panel glass is around 20 kg. Tempered glass can provide this minimum

Assessment of long term reliability of photovoltaic glass–glass modules

Apr 1, 2015 · The investigation presented here applies a classic module assembly for H-patterned cells with a single front glass and a plastic back sheet which is the reference type. The second

Solar Photovoltaic Glass Panel Specifications

When selecting PV glass for solar panels,several key specifications need to be considered to ensure optimal performance and compatibility with project requirements. The thicknessof PV

Transmittance of single-glass photovoltaic panels

Transmittance of single-glass photovoltaic panels The transmittance of a single clear glass in the visible range (380-780 nm) is approximately 90%, as illustrated in Fig. 1 (b). Traditional

Thinner, Taller Solar Modules Prone To Breakages: NREL Report

Dec 13, 2024 · A recent study by NREL showed that some glass always break into small pieces, in a pattern that shows a clear starting point. NREL''s report, "Glass Breakage Is Changing,"

What is Photovoltaic Glass (or solar pv glass)?_

Jul 23, 2025 · 1.1.1 The role of photovoltaic glass The encapsulated glass used in solar photovoltaic modules (or custom solar panels), the current mainstream products are low-iron

What are the requirements for photovoltaic panel glass

What is single laminated PV glass? Single laminated PV glass is the simplest configuration: Structure: Typically consists of two glass panes with a PV layer sandwiched between them.

Photovoltaic double-glass panel glass thickness

The thickness of PV glass plays a crucial role in its structural integrity and performance: Range: Common thicknesses range from 3.2mm to 6mmfor individual glass panes. Configurations:

Solar Photovoltaic Glass Panel Specifications

How to choose PV glass for solar panels? and compatibility with project requirements. The thicknessof PV glass plays a crucial role in its structural integrity and performance: Range:

What is the thickness of the double glass of photovoltaic

Currently, 3.2 mm is the standard thickness for glass front panels in commercial PV modules. Based on the results of this study, this thickness is not suitable for use in hail

Analysis of the Impact Resistance of Photovoltaic Panels

Dec 28, 2023 · The double-glass photovoltaic module is equivalent to a single-layer board, and its effectiveness is verified by compar- ing the impact test results of the double-glass

6 FAQs about [Single-glass photovoltaic panel glass thickness]

How thin is front glass?

However, 2.5 mm glass thickness does allow for frameless designs, which can reduce costs dramatically. Figure 2 – Market share of different front glass thicknesses for modules, where majority front-glass only modules use 3.2mm thickness. This shows how immature very thin glass currently is. Source : ITRPV Fig 1 0

Do PV modules have tempered glass?

Among the current module products on the market, only single-glass modules are equipped with tempered glass. The choice of front and shear materials is critical in determining the module’s ability to withstand hail impacts. Over the past decade, the PV industry has experienced a great revolution.

Why should you choose glass in a PV module?

The choice of glass in a PV module has become a key consideration in efforts to improve durability in the face of extreme weather conditions.

How much does a glass module weigh?

The weight of glass-glass modules are still an issue, with current designs using 2 mm thick glass on each side for framed modules, the weight is about 22 kg, while 2.5 mm on each side will increase the module’s weight to 23 kg. Compared to traditional glass-foil modules, which are about 18 kg, this is a 20% increase in weight.

Can tempered glass be used in solar modules?

The only feasible way for tempered glass to be widely used in solar modules is its application in single-glass modules. The prevailing benchmark for hail resistance, which stipulates that solar modules must be capable of withstanding impacts from hailstones up to 35mm in diameter, may fall short in areas frequently subjected to larger hailstones.

Why should you choose double-glass solar panels?

Double-glass modules boast increased reliability, especially for utility scale PV projects. These include better resistance to higher temperatures, humidity and UV conditions and have better mechanical stability, reducing the risk of microcracks during installation and operation.

Update Information

- Huawei glass photovoltaic panel customization

- Photovoltaic glass panel spherical

- The lowest thickness of photovoltaic glass

- Kyrgyzstan Photovoltaic Glass Panel Company

- Lebanon Photovoltaic Glass Panel Factory

- Photovoltaic glass panel customization

- Photovoltaic silicon glass panel

- Photovoltaic panel glass weight

- Single-glass photovoltaic panel manufacturers

- Ulaanbaatar Northwest Photovoltaic Panel Specifications and Models

- Is the glass of photovoltaic panels so brittle

- Price of a flexible photovoltaic panel

- How many batteries are there in a 1 megawatt photovoltaic panel

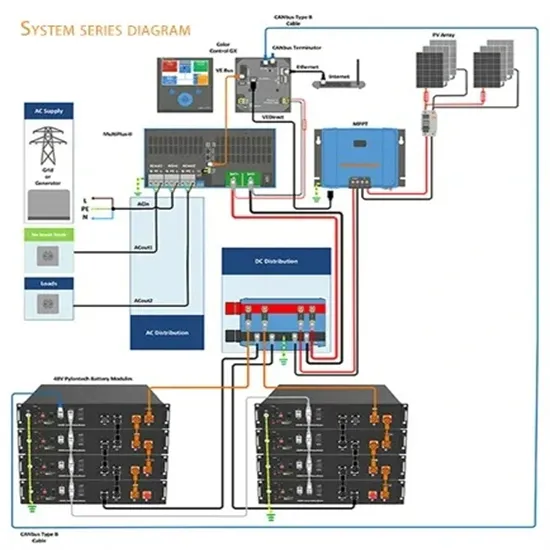

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.