Structure and basic properties of photovoltaic module

Jan 1, 2016 · Introduction To take advantage of renewable photovoltaic energy it is essential to have capable photo electronics properly protected against environmental factors like climate or

Aluminum Foil Reduces Temperature of Double-Glass PV Modules

A study by Nanchang University explores using aluminum foil inside photovoltaic modules to improve thermal conductivity and cooling, enhancing temperature uniformity and solar panel

INSTRUCTIONS FOR PREPARATION OF PAPERS

Jul 12, 2025 · ABSTRACT: Double-glass modules provide a heavy-duty solution for harsh environments with high temperature, high humidity or high UV conditions that usually impact

Conductive adhesive based shingled solar cells: Electrical

Sep 15, 2022 · Abstract Shingled solar cells based on electrically conductive adhesive (ECA) interconnection have emerged as a commercially viable option for photovoltaic (PV) modules

Reducing the temperature of monofacial double-glass photovoltaic module

Apr 1, 2025 · Few studies have shown the in-plane thermal conductivity influence on the temperature of PV modules. In this paper, Al foil with high thermal conductivity was introduced

DuraMAT May 2020 Webinar Backsheet Materials for PV

Mar 6, 2023 · Water spray (front and back) Mechanical loading System voltage bias (±1500 V) Variable load resistors 6x 4-cell mini-module 8x single-cell modules Multiple coupons

Photovoltaic conductive glass, solar cell double-glass module

A conductive glass, photovoltaic technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of high fragmentation rate,

Installation Manual( Double glass PV module)

Mar 9, 2023 · The Purpose This installation manual provides installation instructions for the double glass solar modules (hereinafter referred to as double glass PV modules) of Ningbo

The Performance of Double Glass Photovoltaic Modules

Sep 1, 2017 · Canadian Solar''s Dymond double glass module passed 3 times IEC standard test and IEC 61730-2:2016 multiple combination of limit test and obtained VDE report, which fully

Double-glass PV modules with silicone encapsulation

May 21, 2024 · Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a

The Performance of Double Glass Photovoltaic Modules

Sep 1, 2017 · In recent years, with the rapid development of the photovoltaic industry, double glass module as a high reliability and high weather resistance product is favored by many PV

Double Glass Module Photovoltaic Glass Market

Key Drivers Accelerating Double Glass Module Adoption in the Global Photovoltaic Market The shift toward double glass modules in the photovoltaic industry is driven by their **superior

Finite Element Modeling, Thermal–Mechanical Coupling

Sep 1, 2022 · Request PDF | Finite Element Modeling, Thermal–Mechanical Coupling Analysis, and Demonstration of Multibusbar Half-Cell Double-Glass Overlapping Photovoltaic Module

Failure modes of silicon heterojunction photovoltaic modules

Dec 1, 2024 · In addition to cell performance, photovoltaic (PV) modules should continue to produce more than 80% of their initial output for at least 25 years [5].

SolarSpace Double Glass Photovoltaic Modules

Jun 17, 2025 · Introduction Thanks for choosing photovoltaic modules from SolarSpace Technology Co., Ltd. This manual contains the information regarding the installation and safe

Finite Element Modeling, Thermal–Mechanical Coupling

Jul 25, 2022 · The gap-free interconnect using structural round ribbons in overlapping photovoltaic modules is an effective measure to improve module efficiency. Cells in the overlapping module

Transparent Backsheets for Bifacial Photovoltaic Modules

Jun 15, 2020 · Bifacial modules now represent a growing percentage of the PV module market due to their higher output power and more effective use of the available light for photovoltaic

Aluminum Foil Reduces Temperature of Double-Glass PV Modules

Researchers from Nanchang University in China and Chinese PV manufacturer Jiangxi Rainbow PV conducted the study. A study by Nanchang University explores using aluminum foil inside

Installation Manual( Double glass PV module)

Dec 16, 2020 · The Purpose This installation manual provides installation instructions for the double glass solar modules (hereinafter referred to as double glass PV modules) of Ningbo

Experimental investigation on the combustion performance

Jun 15, 2025 · Under similar glass material conditions, double-glazed modules exhibited superior combustion performance compared to their single-glass counterparts. Therefore, locations

What is the difference between a double-sided double-glass

May 22, 2025 · The difference between double-sided double-glass n-type monocrystalline solar photovoltaic module and ordinary components is reflected in multiple dimensions, from core

6 FAQs about [Is double glass in photovoltaic modules conductive ]

Are double-glass PV modules durable?

Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability.

What is double glass PV module?

Double glass PV module is known as the ultimate solution for the module encapsulation technique. Although double glass modules have many advantages, they are not yet widely used in photovoltaic power plants, for which one important reason is the large power loss due to the transmission of light in the cell gap region.

Are double glass PV modules safe?

Double glass PV modules is an area of significant investigation by many companies and institutes in recent years, for example Dupont, Trina, Apollon, SERIS, MIT, Meyer Burger and Talesun. According to the literature, double glass also has some potential risks besides the abovementioned advantages.

What is a double-glass solar module?

ABSTRACT: Double-glass modules provide a heavy-duty solution for harsh environments with high temperature, high humidity or high UV conditions that usually impact the reliability of traditional solar modules with backsheet material.

Can a double-glass PV module withstand snow and ice?

frameless double-glass module and a traditional PV module with a 3.2mm glass with an aluminum frame were both qualified to withstand heavy accumulations of snow and ice under a high pressure of 5400Pa up to 6700Pa. modules are connected electrically in series until a maximum string voltage of 600 volt or 1,000 volt is achieved.

What is a double glass c-Si PV module?

Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by major PV manufacturers. These modules use a sheet of tempered glass at the rear of the module instead of the conventional polymer-based backsheet. There are several reasons why this structure is appealing.

Update Information

- Middle East double glass photovoltaic modules

- Conductive glass for photovoltaic modules

- Russia St Petersburg double glass photovoltaic modules

- Huawei Australia double glass modules

- Malta double glass photovoltaic curtain wall customization

- Tunisia double glass photovoltaic module price

- Photovoltaic installation of double glass components

- Africa double glass photovoltaic curtain wall price

- Armenian photovoltaic conductive glass manufacturer

- Disadvantages of glass photovoltaic modules

- Photovoltaic conductive glass manufacturers

- Mbabane cheap monocrystalline double glass modules

- Double glass photovoltaic power generation installation

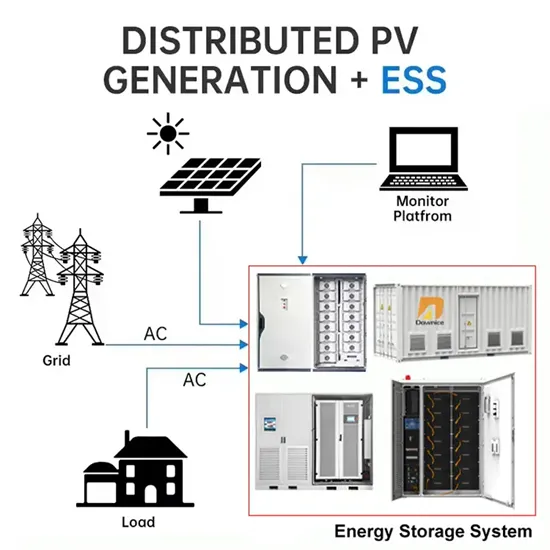

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

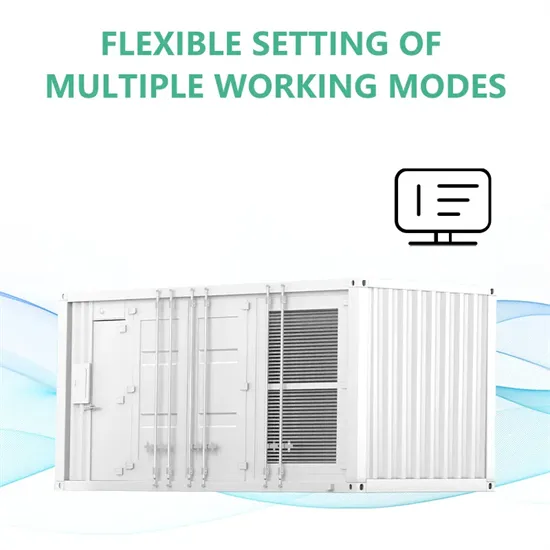

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.