Uses for Electrically Conductive Epoxy (ECE) | MG Chemicals

1 day ago · In designs that utilize a conductive backsheet or modules with ribbon interconnects, ECEs form critical connections that must withstand extreme environmental conditions.

Transparent Backsheets for Bifacial Photovoltaic Modules

Jun 15, 2020 · Bifacial modules now represent a growing percentage of the PV module market due to their higher output power and more effective use of the available light for photovoltaic

Solar Glass & Mirrors, Photovoltaics | Solar Energy

Glass is used in photovoltaic modules as layer of protection against the elements. In thin-film technology, glass also serves as the substrate upon which the photovoltaic material and other

Analysis of solar cells interconnected by electrically conductive

Aug 1, 2019 · Interconnection of solar cells by an electrically conductive adhesive (ECA) can replace the use of conventional metal ribbon connections for photovoltaic module fabrication.

Reducing the temperature of monofacial double-glass photovoltaic module

Apr 1, 2025 · The results show that the temperature decreases gradually from the center to the edge of the PV module, and the maximum temperature and the in-plane temperature

Revisiting Photovoltaic Module Antireflection Coatings: A

Dec 8, 2024 · The antireflection (AR) coating applied to solar glass in photovoltaic modules has remained largely unchanged for decades, despite its well-documented lack of durability.

Failure modes of silicon heterojunction photovoltaic modules

Dec 1, 2024 · These works pointed to the soda-lime glass as the source of degradation, and in particular, the sodium ions (Na +) contained in this type of glass. In fact, the soda-lime glass is

Photovoltaic Conductive Glass Market 2025: Key

May 29, 2025 · The Global Photovoltaic Conductive Glass Market Report 📊 is seeing strong growth 📈 because of better technology 💡 and more demand in

Ultrathin Glass for the Photovoltaic Applications

Mar 9, 2021 · In this work we demonstrate that chemically strengthened ultrathin glass is a perfect material for the photovoltaic applications, i.e. as a substrate for deposition of thin layers and for

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · Glass mitigates these losses by functioning as a protective layer, optical enhancer, and spectral converter within PV cells. Glass-glass encapsulation, low-iron tempered glass, and

Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · Photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by laminating into solar cells, and has relevant

Influence of encapsulation materials on the thermal

Aug 1, 2021 · The prime rule for operating a concentrated photovoltaic (CPV) system is using lenses or mirrors to increase the solar radiation rate. The received solar radiation is directed to

Japan PV Glass (Solar Glass; Solar Photovoltaic Glass) Market

6 days ago · PV Glass (Solar Glass; Solar Photovoltaic Glass) Market The PV Glass (Solar Glass; Solar Photovoltaic Glass) Market is experiencing robust growth, driven by the

Effects of PV Module Soiling on Glass Surface Resistance

Nov 4, 2015 · PID risk due to soiling that causes increased module surface conductivity. Sea salt on 60-cell mc-Si commercial modules promoted increases in leakage current, especially at

Photovoltaic electrochromic device for solar cell module and

Apr 1, 2012 · An innovative concept of solution type photovoltaic electrochromic (PV-EC) device has been developed. The device includes a semi-transparent silicon thin-film solar cell (Si

Thermally conductive and electrically insulating EVA

Apr 29, 2008 · Abstract. A new way of improving the heat dissipating ability and PV efficiency of the solar cells by enhancing the ther-mal conductivity of the rear EVA layer was reported. The

Sustainable Solar Module Through the

Dec 26, 2024 · Sustainability and resource-efficiency are the major topics for the 21st century. Most of the PV modules are manufactured of glass, polymers, metals, and silicon-based solar

Glass and Coatings on Glass for Solar Applications

We then turn to glass and coated glass applications for thin-film photovoltaics, specifically transparent conductive coatings and the advantages of highly resistive transparent layers.

Damp-Heat–Induced Degradation of Lightweight Silicon

Jan 12, 2025 · Lightweight photovoltaic applications are essential for diversifying the solar energy supply. This opens up vast new scenarios for solar modules and significantly boosts the

6 FAQs about [Conductive glass for photovoltaic modules]

What is Photovoltaic Glass?

Photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by laminating into solar cells, and has relevant current extraction devices and cables. The glass used in photovoltaic power generation is not ordinary glass, but TCO conductive glass.

What is electrically conductive glass?

Increasingly, electrically conductive glass is used in photovoltaic modules as the front contact of the solar cell, to form a system which generates a direct electrical current. The United States and the European Union in particular, are encouraging the production of renewable energy.

Which cover material should be used for PV modules?

Currently, 3-mm-thick glass is the predominant cover material for PV modules, accounting for 10%–25% of the total cost. Here, we review the state-of-the-art of cover glasses for PV modules and present our recent results for improvement of the glass.

Why is glass used in photovoltaic modules?

Glass is used in photovoltaic modules as layer of protection against the elements. In thin-film technology, glass also serves as the substrate upon which the photovoltaic material and other chemicals (such as TCO) are deposited. Glass is also the basis for mirrors used to concentrate sunlight, although new technologies avoiding glass are emerging.

Which materials are used in photovoltaic panels?

The remaining 20 –25% encompassed fiberglass (including reinforcement, insulation, and mineral wool fibers) and specialty glass manufacturing . Flat glass transparency, low-iron glass improves photovoltaic (PV) panel efficiency. This seg- emphasis on energy efficiency and sustainability. Refs. [35, 36].

Why is glass used in PV cells?

Glass mitigates these losses by functioning as a protective layer, optical enhancer, and spectral converter within PV cells. Glass-glass encapsulation, low-iron tempered glass, and anti-reflective coatings improve light management, durability, and efficiency.

Update Information

- Conductive glass for photovoltaic modules

- Armenian photovoltaic conductive glass manufacturer

- Grenada double glass photovoltaic modules

- Do shingled photovoltaic modules have glass

- Greece a benefit photovoltaic conductive glass

- Russia St Petersburg double glass photovoltaic modules

- Disadvantages of glass photovoltaic modules

- Tuvalu photovoltaic conductive glass manufacturer

- Double-sided glass photovoltaic sun room

- Muscat Photovoltaic Glass Northwest

- Panama environmentally friendly photovoltaic glass research and development

- Tripoli double glass photovoltaic curtain wall supplier

- Slovenia non-standard photovoltaic glass cells

Solar Storage Container Market Growth

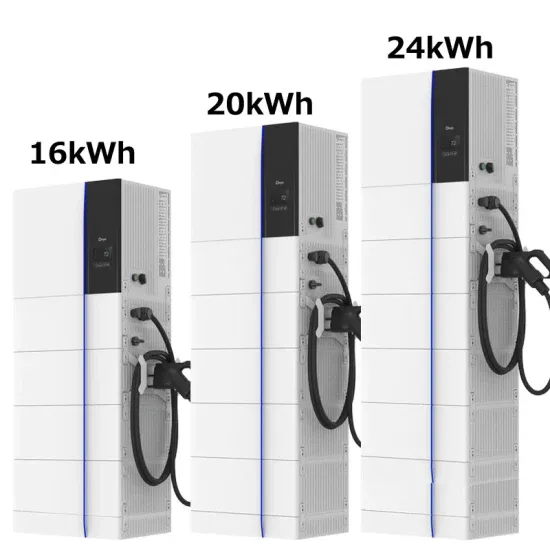

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.