Energy storage container battery assembly drawings

What is a battery energy storage system (BESS) container design sequence? The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design

Understanding Battery Pack Technology: Key

Mar 14, 2025 · This integrated system powers everything from electric vehicles to renewable energy storage, making battery pack technology crucial for modern energy solutions. ### Key

Unpacking the Components of a Battery Energy

Jun 3, 2023 · In sum, a Battery Energy Storage System is a complex assembly of interrelated components, each playing its crucial role in storing and managing

Energy storage container assembly design

By definition, a Battery Energy Storage Systems (BESS) is a type of energy storage solution, a collection of large batteries within a container, that can store and discharge electrical energy

Comprehensive Lifecycle Planning and Design Analysis of

May 31, 2024 · Explore the full lifecycle of containerized energy storage systems, from planning and design to decommissioning. Learn about safety considerations, economic factors, and

Battery Pack Assembly Process Series 9

Jun 12, 2025 · Battery energy storage systems are mainly divided into: container energy storage, industrial and commercial energy storage, household energy storage and portable energy

Energy storage container assembly line process standards

Energy storage container assembly line process standards Specialized containers are the backbone of various industries, ensuring the safe and efficient transportation and storage of

Energy storage container assembly line process standards

Energy Storage Container is an energy storage battery system, which includes a monitoring system, battery management unit, particular fire protection system, special air conditioner,

Key Design Principles for Battery Pack Structures in Energy Storage

Nov 25, 2024 · Explore essential design guidelines for battery pack structures in energy storage systems, focusing on safety, adaptability, thermal protection, and manufacturing efficiency,

fenrg-2022-846741 1..15

Mar 30, 2022 · The earliest application of prefabricated cabin type energy storage in power grids is originated in Europe and North America, where the energy storage container (ESC)

Battery Pack Assembly Process Series 7

Jun 6, 2025 · The composition structure of the energy storage container is complex, mainly including the following key parts: container, battery pack, electrical system, fire protection

Installation process inside the energy storage container

Containerized Battery Energy Storage Systems (BESS) are essentially large batteries housed within storage containers. These systems are designed to store energy from renewable

Energy storage container battery assembly sequence

What is a battery energy storage system (BESS) container design sequence? The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design

How is the electrical assembly of the energy storage container

TL;DR: In this article, an electrical structure for an energy-storing battery container is presented, which consists of a battery assembly, an auxiliary device, a bus cabinet, and an external

Installation process of energy storage container

Installation process of energy storage container A battery energy storage system (BESS) captures energy from renewable and non-renewable sources and stores it in rechar. eable batteries

What the process of assembly of industrial energy storage

In an era of growing demand for sustainable energy sources and the search for efficient solutions leading to energy independence, industrial energy storage systems are becoming an

How Should Energy Storage Containers Be Designed?

Mar 7, 2025 · 3) Reduce the impact on the structure of electrical equipment. 4) During the partitioning process, it is necessary to ensure the cleanliness of the energy storage container

The Art and Science of Energy Storage Equipment Assembly:

Let''s face it – when most people hear "energy storage equipment assembly," they imagine technicians casually snapping battery modules together like LEGO bricks. But in reality, this

Container energy storage battery manufacturing process

A Lithium Battery Storage Container securely houses lithium-ion batteries for efficient energy storage, essential for renewable energy integration, backup power, and grid

Update Information

- Is the energy storage container assembly process difficult

- Energy storage container design and installation plan and process

- Energy storage container inspection process

- Internal electrical system of energy storage liquid cooling system

- British energy storage container manufacturer

- Rabat Energy Storage Container Fire Fighting System Base Station

- Praia walk-in energy storage container quotation

- Energy storage container base station power generation site

- Liquid-cooled energy storage battery container

- How big is the energy storage container factory

- Bangladesh energy storage container power station quotation

- Energy storage container types

- Kuwait City container energy storage cabinet manufacturer

Solar Storage Container Market Growth

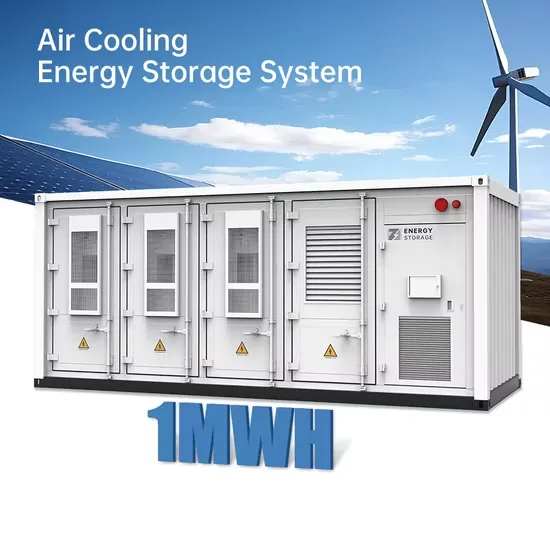

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.