Why Container Energy Storage Quality Inspection is Your

Let''s face it – container energy storage systems are the unsung heroes of the renewable energy revolution. These giant metal boxes packed with batteries are quietly powering everything from

Comprehensive Lifecycle Planning and Design Analysis of

May 31, 2024 · Explore the full lifecycle of containerized energy storage systems, from planning and design to decommissioning. Learn about safety considerations, economic factors, and

daily inspection process of energy storage equipment

About daily inspection process of energy storage equipment As the photovoltaic (PV) industry continues to evolve, advancements in daily inspection process of energy storage equipment

Container energy storage system inspection

By adopting a shipping container energy storage system, you are not just investing in a piece of technology; you are endorsing a sustainable future.Whether for personal use, community

Energy storage cabinet inspection process

energy storage systems listed to UL 9540. Con Edison Energy Storage System Guide Version 2 / December 2018 Provides high level details of the electric interconnection process, typical

Designing a BESS Container: A Comprehensive Guide to Battery Energy

Apr 10, 2023 · The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system.

SPCC Guidance for Regional Inspectors, December 16,

Jun 25, 2021 · For example, some inspection and testing provisions apply specifically to bulk storage containers at onshore facilities (other than oil production facilities) while other

Energy Storage System Safety: Plan Review and

Apr 4, 2017 · acting the timely deployment of safe energy storage systems (ESS). The timely deployment of safe ESS is affected by the ability of relevant parties to document and validate

Container inspection and certification process/ | Upfreights

Learn about container inspection and certification process/ in our comprehensive freight forwarding guide. Expert insights for international shipping and logistics.

Inspection and installation of container energy storage

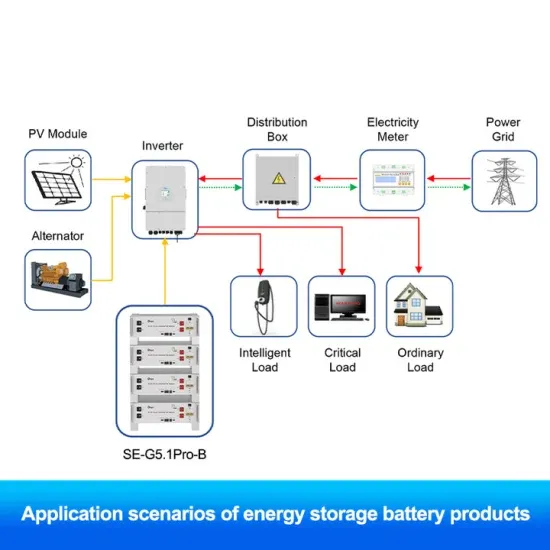

What is a containerized battery energy storage system? Our''s Containerized Battery Energy Storage Systems (BESS) offer a streamlined,modular approach to energy storage. Packaged

The Ultimate Guide to Energy Storage Container

Who Cares About Energy Storage Containers? (Spoiler: Everyone) Ever tried assembling IKEA furniture without the instruction manual? That''s what deploying energy storage containers feels

Container energy storage quality inspection

Sinovoltaics advice: we suggest having the logistics company come inspect your Battery Energy Storage System at the end of manufacturing,in order for them to get accustomed to the BESS

What are the inspection standards for energy

Sep 28, 2024 · Inspection standards are established by various organizations to ensure that energy storage systems function safely, efficiently, and reliably.

Energy storage container inspection process

The whole inspection process runs through the manufacturing process of containers, not limited to the final product, and adjusts production at any time to ensure welding quality. 2 LIFTING

SPCC Bulk Storage Container Inspection Fact Sheet

Jun 25, 2021 · Bulk Storage Container Inspection Fact Sheet The inspection requirements of the SPCC rule are designed to detect oil leaks, spills, or other potential integrity or structural

Energy Storage Product Inspection Standards: What You

Jul 25, 2021 · Energy storage product inspection standards act as the ultimate quality control checklist, preventing your clean energy dreams from literally going up in smoke. From Tesla

Battery Pack Assembly Process Series 9

Jun 12, 2025 · Battery energy storage systems are mainly divided into: container energy storage, industrial and commercial energy storage, household energy storage and portable energy

Energy storage container processing and integration

This recommended practice addresses energy storage containers. The document defines technical recommendations on the design, manufacture, electrical equipment installation,

How To Ship Heavy-Duty Energy Storage Containers

Aug 4, 2025 · Container Survey: Conduct a thorough inspection of the energy storage container to assess its structural integrity. Identify any pre-existing damage or potential weaknesses that

Container energy storage liquid cooling system

EnerC liquid-cooled energy storage battery containerized energy storage system is an integrated high energy density system,which is in consisting of battery rack system,battery management

Update Information

- The whole process of container energy storage ship

- Is the energy storage container assembly process difficult

- What are the container energy storage businesses

- Australia Sydney container photovoltaic energy storage company

- Energy Storage Container Transformer

- Energy storage charging container base station

- How long does it take to install an energy storage container

- Which container energy storage manufacturers are there in Norway

- The latest solar energy storage container brand

- Energy Storage Container Requirements

- Lithium battery energy storage container testing standards

- Outdoor Wireless Energy Storage Container Base Station

- Energy Storage Battery Container Cost

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.