Improvement of Low-Switching-Frequency Rectifier With

Feb 12, 2025 · In this article, a hybrid cascaded H-bridge multilevel rectifier is proposed to improve the overall performance by cascading a high-frequency switching cell. The added cell

Inverter design using high frequency

Feb 27, 2021 · We are converting DC to AC (Square wave) with the help of switching device like MOSFET and then again converting it into DC by the process of rectification by high frequency

Understanding High-Frequency Transformer Rectifiers: A

Mar 17, 2025 · The rectification process in a high-frequency transformer rectifier involves converting the AC voltage generated by the transformer into DC voltage. Various types of

Modeling and simulation of three-phase IGBT full-bridge inverter

Aug 1, 2024 · Therefore, this also creates hardware computing conditions for simulating the high-frequency switching action of switching elements in the three-phase IGBT full-bridge inverter

Rectifier vs Inverters & Converters: What is the

Oct 4, 2017 · Find out the difference between an inverter, converter, transformer, and rectifier with a short video and learn more about electronic components

Phase-Shifted Full-Bridge Converter Fundamentals

Nov 20, 2024 · An LLC-SRC uses frequency modulation for voltage regulation, while a PSFB and DAB both use phase-shift control with a fixed switching frequency for voltage regulation. An

H Bridge Inverter Circuit using IC SG3525 and

Jan 9, 2025 · The SG3525-based H-Bridge inverter circuit converts low-voltage DC into high-voltage AC, making it ideal for use in applications like renewable

Design and control of a novel topology for multilevel inverters

Aug 1, 2023 · The requirement of more than one source in multilevel inverters is an issue to be solved for applications with a single DC source. One solution to this problem is to obtain the

Frequency Inverter Basic: Introduction, Functions

Dec 11, 2023 · According to the use classification, it can be divided into general-purpose inverter, high-performance special inverter, high-frequency inverter,

Design and implementation of a novel switched rectifier

In this study, a hybrid approach is presented for the asymmetric Cascaded H-Bridge (CHB) MLI topology. Two switches are added to the High Frequency Link (HFL) circuit to allow the HFL

Current-fed dual-half-bridge converter directly connected

Nov 1, 2018 · The chosen converter is composed of a high frequency inverter, a high-frequency transformer and a full bridge rectifier as depicted in Fig. 4 [1,19–22]. A fuel cell side full bridge

Equivalent Impedance Analysis and Compensation of Full-Wave Bridge

May 28, 2021 · Full-wave bridge rectifiers are widely used in power electronics for ac-dc conversion. In most of the conventional rectifier analysis, the diodes were modeled as

Full-Bridge Inverter Circuits | Tutorials on Electronics | Next

Aug 3, 2025 · PDF Voltage Source Inverter Design Guide (Rev. B) - TI E2E support forums — A typical inverter comprises of a full bridge that is constructed with four switches which can be

Phase-Shifted Full-Bridge Converter Fundamentals

Nov 20, 2024 · The phase-shifted full-bridge converter (PSFB) is common in high-performance power supplies with fast transient response, high power density and high converter eficiency.

Voltage Fed Full Bridge DC-DC & DC-AC Converter High

Apr 1, 2023 · In many applications, it is important for an inverter to be lightweight and of a relatively small size. This can be achieved by using a High-Frequency Inverter that involves an

Bidirectional High-Frequency Link Inverter with

The main conversion circuits are the high-frequency PWM bridge, the active rectifier and the polarity-reversing bridge. First, The dc voltage, Vdc is converted into a high-frequency PWM

Design and Simulation of High Frequency Inverter for PV

Mar 8, 2022 · A high frequency link photovoltaic (PV) power conditioning system which includes a high frequency resonant inverter, a rectifier, and a line commutated inverter, operating near

A Single Stage ZVS-PWM Inverter for Induction Heating

Oct 27, 2016 · This one-stage high frequency inverter which is composed of single phase diode bridge rectifier, non-smoothing filter, boost-active clamp bridge type zero voltage soft switching

Novel multiâ level inverters with flyback high frequency

Jan 13, 2021 · At present, there are few researches on high frequency isolated multi-level inverter (HFI-MLI), since the line-frequency transformer is too large to be accepted and the high

6 FAQs about [High frequency inverter is bridge rectifier]

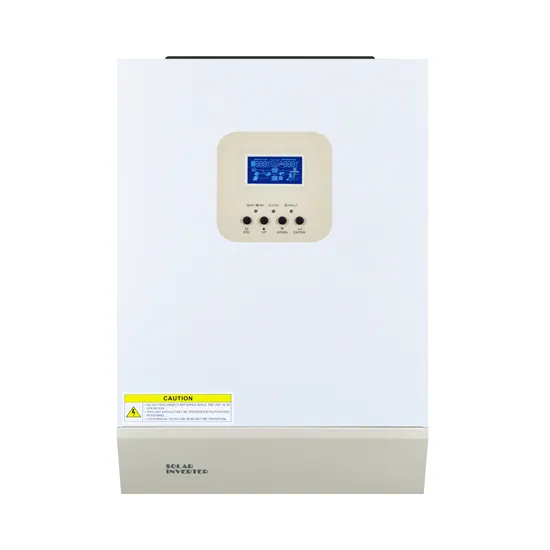

What is a high frequency inverter?

In many applications, it is important for an inverter to be lightweight and of a relatively small size. This can be achieved by using a High-Frequency Inverter that involves an isolated DC-DC stage (Voltage Fed Push-Pull/Full Bridge) and the DC-AC section, which provides the AC output.

What is a bridge type inverter?

The simplest form of an inverter is the bridge-type, where a power bridge is controlled according to the sinusoidal pulse-width modulation (SPWM) principle and the resulting SPWM wave is filtered to produce the alternating output voltage. In many applications, it is important for an inverter to be lightweight and of a relatively small size.

How do bridge rectifiers work?

The bridge rectifiers (D1D4) convert the square-wave signal back to DC voltage and store it in the intermediate circuit (L1+C2). A second full bridge (S5S8) then generates a 50 Hz AC voltage, which is smoothed to a sinusoidal 50 Hz AC voltage via the chokes (L2+L3) before being fed into the public grid. Figure 2-1.

What is a sg3525 based H-bridge inverter?

The SG3525-based H-bridge inverter circuit is a reliable and efficient solution for converting DC voltage to AC power. With features such as voltage regulation and low battery protection, it is suitable for powering a wide range of devices.

Which power supply topologies are suitable for a high frequency inverter?

The power supply topologies suitable for the High-Frequency Inverter includes push-pull, half-bridge and the full-bridge converter as the core operation occurs in both the quadrants, thereby, increasing the power handling capability to twice of that of the converters operating in single quadrant (forward and flyback converter).

How does a full-bridge rectifier work?

With a full-bridge rectifier, a diagonal pair of diodes conducts current to energize LO when the transformer secondary winding voltage is positive, and the other diagonal pair of diodes conducts current to energize LO when the transformer secondary winding voltage is negative.

Update Information

- Bangkok high frequency inverter price

- Which brand should I choose for high frequency inverter

- Korean high frequency inverter installation

- Nh199kw high frequency inverter accessories

- Lisbon high frequency inverter price

- Austria high frequency power inverter

- High frequency inverter can use half wave

- Yemen high frequency inverter price

- What is a high frequency pwm inverter

- High frequency inverter produces sine wave

- High frequency inverter adjusts output voltage

- Sophia high frequency inverter manufacturer

- High frequency inverter converted to water cooling

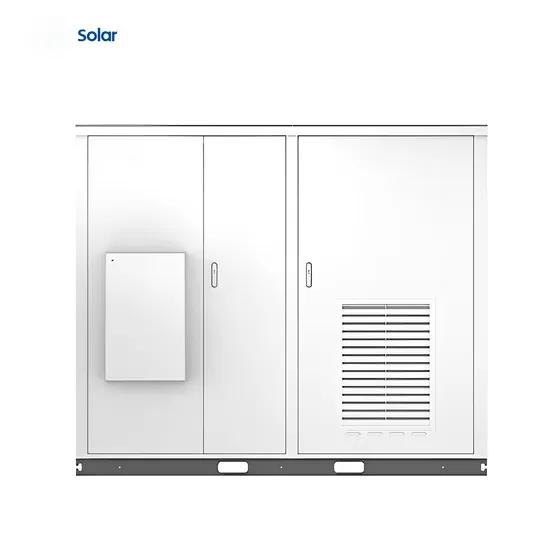

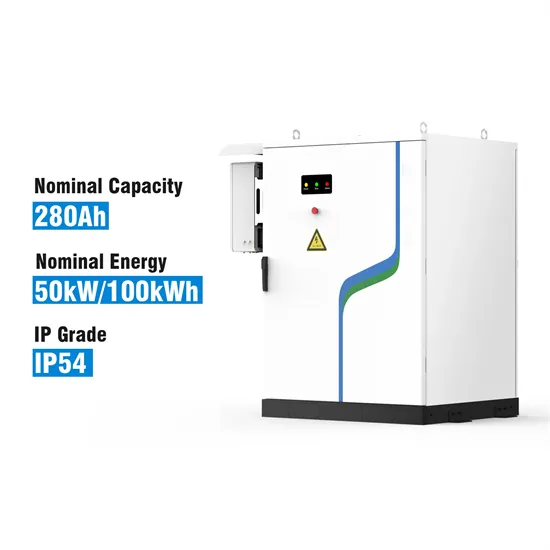

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.