What is a photovoltaic inverter?Selection, Principles & Future

Apr 28, 2025 · Gain a deep understanding of the working principles, key classifications, and crucial roles of photovoltaic inverters in solar power generation systems. This article

What auxiliary materials are needed for photovoltaic inverters

BIS has Required Utility-interconnected Photovoltaic Inverters To Be Registered As Per AUXILIARY. STANDARDIZATION (SCIENTIFIC) DIVISION non-islanding inverters for DC

Introduction to 6 Auxiliary Materials of Photovoltaic Modules

Backplane material and structural design: The most common are TPX, KPX and PET, among which T film (PVF) and K film (PVDF) in the "sandwich" structure are fluorine-containing film

How To Cool Solar Inverter And Make It Last

Jul 10, 2022 · The solar inverter is an inverter dedicated to the field of solar photovoltaic power generation, which converts the direct current generated by

Switching and Protection solutions for 800VAC

Mar 22, 2024 · Why you need a Switching & Protection solution for AC Recombiners Every feeder from the relative inverter requires adequate galvanic switching and protection against

What are the Best Practices & Considerations in

Apr 14, 2021 · For a Solar PV project – panels, inverters, structures, HT Panels, LT Panels & transformers make up about 90% of the material cost. Hence,

Changes and challenges of photovoltaic inverter with silicon carbide

Oct 1, 2017 · 1. Introduction With the continuous decrease in the cost of photovoltaic (PV) modules and inverters, solar energy has become a competitive source of renewable energy

PHOTOVOLTAIC MODULE AUXILIARY MATERIAL LIST

Does the photovoltaic auxiliary material include an inverter Inverters used in photovoltaic applications are historically divided into two main categories: 1. Standalone inverters 2. Grid

Inverter Transformers for Photovoltaic (PV) power plants:

Dec 22, 2022 · In this paper, the author describes the key parameters to be considered for the selection of inverter transformers, along with various recommendations based on lessons

Technical specifications for solar PV installations

Nov 22, 2023 · 1. Introduction The purpose of this guideline is to provide service providers, municipalities, and interested parties with minimum technical specifications and performance

What equipment and materials are needed to connect to

What is photovoltaic (PV) technology and how does it work? PV materials and devices convert sunlight into electrical energy. A single PV device is known as a cell. An individual PV cell is

Does the photovoltaic auxiliary material include an inverter

The price for a PV module is in the very moment high compared with other sources. The lowest price for a PV module, inclusive inverter, cables and installation, is approximately 30 DKK! per

Photovoltaic inverter secondary power supply

Why do solar inverters need auxiliary power supply? The control domain,consisting of microcontrollers,gathers information from all of the above to enable efficient and reliable power

What are the photovoltaic auxiliary material inverters

We distinguish three classes of PV materials: (i) ultrahigh-efficiency monocrystalline materials with efficiencies of >75% of the S-Q limit for the corresponding band gap: Si (homojunction and

An Introduction to Inverters for Photovoltaic

Jun 3, 2020 · An Introduction to Inverters for Photovoltaic (PV) Applications This article introduces the architecture and types of inverters used in photovoltaic

Photovoltaic Module Auxiliary Materials Market

What are the primary demand drivers for photovoltaic module auxiliary materials across different global regions? The demand for photovoltaic (PV) module auxiliary materials—such as

TECHNICAL SPECIFICATIONS OF ON-GRID SOLAR PV

Feb 3, 2021 · The PV Module should be under the Indigenous / DCR (Domestic Content Requirement) category (Based on the specific requirement). The PV modules shall conform to

What auxiliary materials do photovoltaic cells need

PV Module-Eight Key Auxiliary Materials For example, N-type modules require high-performance encapsulation materials such as POE with superior physical properties and resistance to

What are the auxiliary materials for photovoltaic panels

These auxiliary materials not only directly affect the performance and lifespan of PV modules but also provide essential support in ensuring the stability and efficiency of PV

Update Information

- What are the photovoltaic auxiliary material inverters

- What are the string photovoltaic inverters

- What does igbt mean for photovoltaic inverters

- How many inverters are needed to switch to photovoltaic

- What inverters are used in photovoltaic power stations

- Photovoltaic standards for communication base station inverters

- Can wind power be generated by photovoltaic inverters

- What is the auxiliary power supply voltage of the inverter

- What voltage is good for solar inverters

- What brand of photovoltaic inverter gw

- What is the charging voltage of a 100w photovoltaic panel

- What kind of vehicle is used to transport photovoltaic glass

- What are battery modules and photovoltaic modules

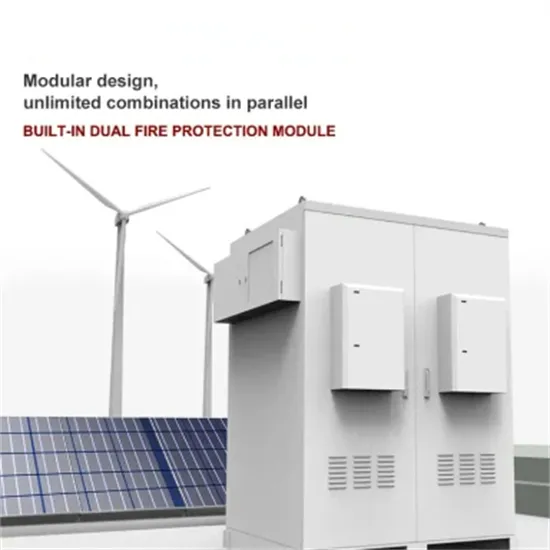

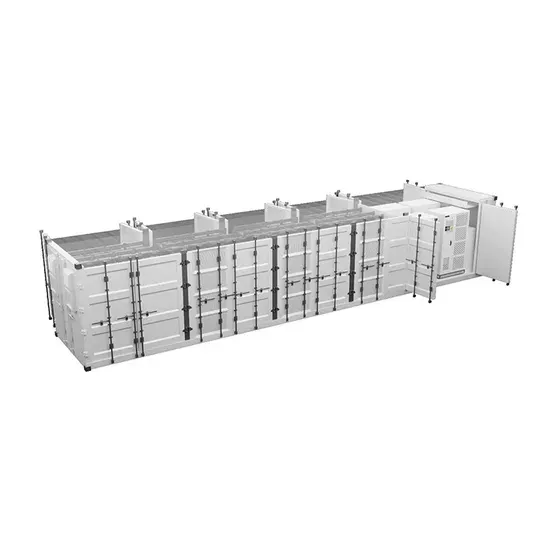

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

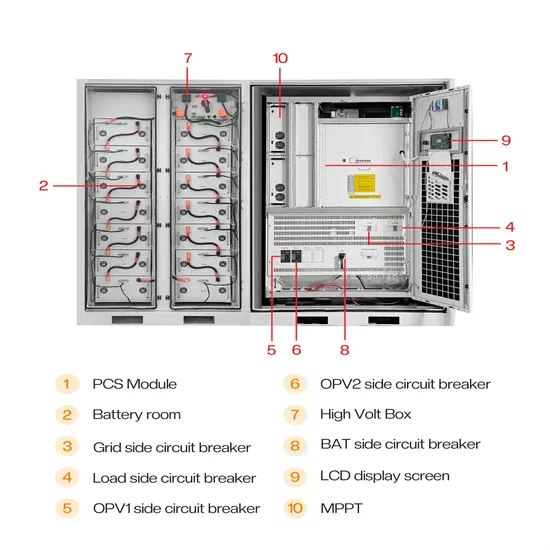

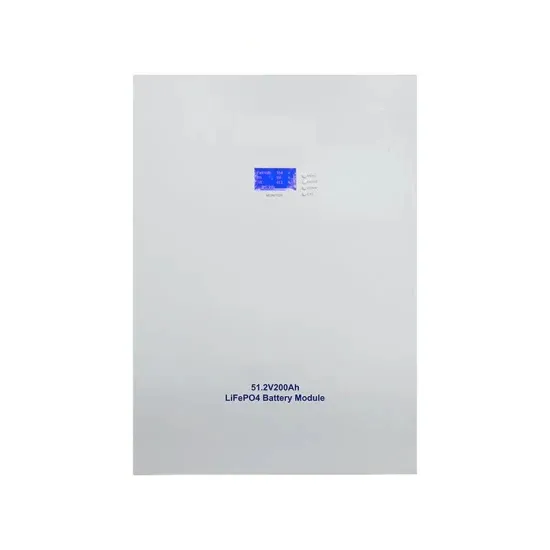

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.