What auxiliary materials are needed for photovoltaic inverters

BIS has Required Utility-interconnected Photovoltaic Inverters To Be Registered As Per AUXILIARY. STANDARDIZATION (SCIENTIFIC) DIVISION non-islanding inverters for DC

Photovoltaic inverters: What are they and how

Jul 8, 2024 · Photovoltaic inverters are devices that transform the direct current (DC) generated by solar panels into alternating current (AC). That is, solar

What elements are contained in photovoltaic panel

The rapid proliferation of photovoltaic (PV) modules globally has led to a significant increase in solar waste production, projected to reach 60-78 million tonnes by 2050. all impact the output

An Introduction to Inverters for Photovoltaic

Jun 3, 2020 · An Introduction to Inverters for Photovoltaic (PV) Applications This article introduces the architecture and types of inverters used in photovoltaic

What auxiliary materials are needed for photovoltaic

In PV systems with string inverters, the equipment grounding conductor from the array terminates to the inverter''''s grounding bus bar. All string inverters have a lug or set of

What auxiliary materials are needed for photovoltaic

What auxiliary materials are needed for photovoltaic inverters Check your solar inverter''''s temperature. If it gets too hot, chill it. Solar fans can help. Solar fans cool the inverter by

Photovoltaic inverter secondary power supply

Why do solar inverters need auxiliary power supply? The control domain,consisting of microcontrollers,gathers information from all of the above to enable efficient and reliable power

Photovoltaic panel installation auxiliary materials

What are the UL requirements for a photovoltaic system? Photovoltaic panels and modules shall be listed and labeled in accordance with UL 1703. Inverters shall be listed and labeled in

Photovoltaic auxiliary material support procurement plan

Electrical Plans,including single-line electrical diagramsshowing utility interconnection and all devices comprising the PV system,including,but not limited to: PV arrays,combiner

What are the photovoltaic auxiliary material inverters

We distinguish three classes of PV materials: (i) ultrahigh-efficiency monocrystalline materials with efficiencies of >75% of the S-Q limit for the corresponding band gap: Si (homojunction and

Photovoltaic Module Auxiliary Materials Market

What are the primary demand drivers for photovoltaic module auxiliary materials across different global regions? The demand for photovoltaic (PV) module auxiliary materials—such as

Tips for choosing photovoltaic inverters – 150 POWER

Confirm what power inverters are suitable for installing in your photovoltaic power station The installation capacity of a general power station is calculated based on the land or roof usage

PV Auxiliary Materials: Cost Reduction and Benefits Increase

Jul 13, 2023 · According to statistics from Wood Mackenzie, global shipments of PV inverters have experienced rapid growth since 2016, increasing from 81.3GW to 225.4GW in 2021, with

TECHNICAL SPECIFICATIONS OF ON-GRID SOLAR PV

Feb 3, 2021 · The PV Module should be under the Indigenous / DCR (Domestic Content Requirement) category (Based on the specific requirement). The PV modules shall conform to

Inverter Transformers for Photovoltaic (PV) power plants:

Dec 22, 2022 · In this paper, the author describes the key parameters to be considered for the selection of inverter transformers, along with various recommendations based on lessons

What are the auxiliary materials for photovoltaic panels

These auxiliary materials not only directly affect the performance and lifespan of PV modules but also provide essential support in ensuring the stability and efficiency of PV

PHOTOVOLTAIC MODULE AUXILIARY MATERIAL LIST

Does the photovoltaic auxiliary material include an inverter Inverters used in photovoltaic applications are historically divided into two main categories: 1. Standalone inverters 2. Grid

Photovoltaic panels solar energy auxiliary materials

This review discusses the latest advancements in the field of novel materials for solar photovoltaic devices,including emerging technologies such as perovskite solar cells. It evaluates the

What are the solar energy auxiliary materials? | NenPower

Apr 20, 2024 · Key auxiliary materials include anti-reflective coatings, encapsulants for photovoltaic cells, mounting structures, and thermal management substances.3. Among these,

What are the types of photovoltaic support auxiliary materials

Encapsulant materials used in photovoltaic (PV) modules serve multiple purposes; it provides optical coupling of PV cells and protection against environmental stress.

What are the Best Practices & Considerations in

Apr 14, 2021 · For a Solar PV project – panels, inverters, structures, HT Panels, LT Panels & transformers make up about 90% of the material cost. Hence,

Tips for choosing photovoltaic inverters – 150 POWER

The number of MPPT channels in an inverter largely determines the power generation of a photovoltaic power station, and the number of input channels in an inverter often determines

PHOTOVOLTAIC MODULE AUXILIARY MATERIAL LIST

Inverters used in photovoltaic applications are historically divided into two main categories: 1. Standalone inverters 2. Grid-connected inverters Standalone inverters are for the applications

Photovoltaic auxiliary material inverter manufacturer

The solar inverter manufacturing industry is largely driven by an intensifying global focus on renewable energy. Within this sector,specialized companies thrive on producing solar inverters

Does the photovoltaic auxiliary material include an inverter

Does the photovoltaic auxiliary material include an inverter How Does a Solar Inverter Work? A solar inverter uses solid-state components to convert DC to AC electricity. Unlike older

Update Information

- What auxiliary materials are needed for photovoltaic inverters

- What are the string photovoltaic inverters

- What does igbt mean for photovoltaic inverters

- Photovoltaic panel auxiliary material manufacturers

- Prices of photovoltaic panels and auxiliary materials

- What is the current price of single crystal double glass photovoltaic panels

- What are battery modules and photovoltaic modules

- What are the wattages of photovoltaic panel sizes

- What is the auxiliary power supply voltage of the inverter

- What voltage is good for solar inverters

- What kind of vehicle is used to transport photovoltaic glass

- What are the advantages of flexible photovoltaic panels

- 470 What is the voltage of the photovoltaic panel

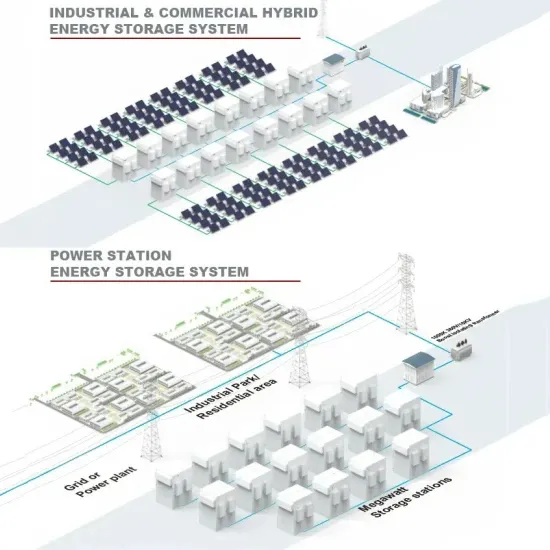

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.