Photovoltaic (PV) thin-films for solar cells

Jan 1, 2012 · The production of PV solar modules is dominated by crystalline silicon whereby silicon cells are connected together and laminated between a coverglass and a back-sheet to

Revolutionizing Solar Power: Unlocking the

Apr 8, 2024 · When comparing thin film cells with traditional crystalline silicon cells, several factors stand out: Efficiency: While crystalline silicon cells

Recent Advances in Flexible Solar Cells;

Feb 21, 2025 · In contrast to conventional PV technologies based on crystalline silicon (c-Si) solar cells (SCs), thin-film technologies rely on complex physical

Crystalline silicon thin films: A promising approach for

In this paper we review the achievements in the field of silicon crystalline thin film solar cells and correlate these with the different types of growth techniques and substrates.

Inventions, innovations, and new technologies: Flexible and

Sep 1, 2023 · Selected notable patents are listed at the end. The objective is to draw attention to the inventions, innovations, and new technologies that thin-film PV could impact, leading to a

Thin Film Vs. Crystalline Solar Panels

5 days ago · A photovoltaic material of a thin layer on top of a solid substrate, such as glass utilize to create thin film solar panels. The solar materials include cadmium telluride (CdTe), copper

Recent progress in silicon photovoltaic module recycling

Dec 1, 2022 · The rapid deployment of solar photovoltaic (PV) technology around the world brings the ineluctable problem of disposing of and recycling decommissioned solar photovoltaic

Thin Film Photovoltaics Global Market Report 2025-2035:

Mar 17, 2025 · Today, the thin film PV market is primarily dominated by First Solar, which has successfully scaled cadmium telluride (CdTe) technology to compete effectively with crystalline

Thin Films in Solar Technology | SpringerLink

Thin film solar cells utilize ultra-thin layers of photovoltaic materials deposited onto substrates, such as glass or flexible plastic. Unlike conventional crystalline silicon cells, which require thick

A model to analyze strategic products for photovoltaic silicon thin

Feb 1, 2011 · Solar cells can be categorized into two main groups: wafer-type (single crystalline or multi-crystalline) and thin film (a-Si, Cd-Te and CIGS). The former are made from wafers cut

Polycrystalline silicon on glass thin-film solar cells: A

Dec 1, 2013 · The crystalline silicon on glass (CSG) solar cell technology is one of the closest among thin-film technologies to the most successful crystalline silicon (c-Si) wafer-based

Emerging innovations in solar photovoltaic (PV)

This review explores briefly conventional light-absorbing materials, including silicon (amorphous silicon and crystalline silicon), cadmium telluride (CdTe), cadmium sulphide (CdS), hybrid PV

Pilot production of thin-film crystalline silicon on glass

May 24, 2002 · Photovoltaic modules using crystalline silicon on glass technology combine the low manufacturing cost of thin films with the established strengths of crystallin

Recent advances and remaining challenges in thin-film silicon

Sep 1, 2015 · We address material and device developments, including (i) improved plasma deposition processes to achieve high-quality dense absorber materials; (ii) absorber layers

Highly Oriented Crystalline Silicon Film for

Jun 23, 2025 · Stanford researchers have patented a low cost, textured crystalline silicon (c-Si) photovoltaic film fabricated via scalable, ion beam assisted

Polycrystalline silicon thin-film solar cells: Status and perspectives

Dec 1, 2013 · The present article gives a summary of recent technological and scientific developments in the field of polycrystalline silicon (poly-Si) thin-film solar cells on foreign

Advances in crystalline silicon solar cell technology for

Jul 22, 2010 · Crystalline silicon photovoltaic (PV) cells are used in the largest quantity of all types of solar cells on the market, representing about 90% of the world total PV cell production in 2008.

Kibing Solar-Make sunlight more efficient

Aug 31, 2022 · The report pointed out that photovoltaic glass, as an indispensable material for photovoltaic modules, has been widely used in both crystalline silicon and thin-film modules.

Electrodeposition of crystalline silicon films from silicon

Dec 18, 2019 · The photovoltaics market has been dominated by crystalline silicon solar cells despite the high cost of the silicon wafers. Here Zou et al. develop a one-step

Solar Cells on Multicrystalline Silicon Thin Films Converted

Sep 2, 2024 · 1 Introduction Crystalline silicon is needed in large and ever-increasing amounts, in particular for photovoltaic (PV) energy conversion. Efficient thin-film absorbers, for example,

Very thin film crystalline silicon solar cells on glass substrate

The performances of thin-film poly-Si solar cells with a thickness of less than 5 /spl mu/m on a glass substrate have been investigated. The cell of glass/back

Advancements in photovoltaic technology: A comprehensive

Apr 1, 2025 · This review provides a comprehensive analysis of recent advancements in PV technology and presents forward-looking insights into future trends. Beginning with a historical

Encapsulation Advancements Extend Life of Thin-Film

Sep 30, 2013 · Thin-film solar cells made from semiconductors such as copper, indium, gallium, and selenium (known as "CIGS") have several advantages over traditional crystalline silicon

What are thin-film solar cells? description, and types

Sep 26, 2019 · Thin-film solar cells are the second generation of solar cells. These cells are built by depositing one or more thin layers or thin film (TF) of photovoltaic material on a substrate,

Photovoltaic device innovation for a solar future

Jul 21, 2023 · PV device performance depends on the coupling of optical absorption, carrier transport, and interface control, fundamentals shared with a wide range of semiconductor

The research progress on recycling and resource utilization

Jun 15, 2024 · With the rapid development of photovoltaic technology, its evolutionary journey primarily encompasses three generations of technology: the first generation being crystalline

Next Generation Crystalline Silicon on Glass Modules Final

Thin-film Crystalline Silicon on Glass (CSG) is a new photovoltaic (PV) technology that uses a very thin layer of a silicon material to fabricate solar cells supported by a cheap transparent

Review of Efficiency of Thin Film Amorphous Silicon

Jun 25, 2023 · ABSTRACT: Amorphous silicon (a-Si) is the non-crystalline form of silicon used for solar cells and thin-film transistors in LCDs ed as semiconductor material for a-Si solar

Building The World''s Thinnest Crystalline Silicon Solar Panel

Tokyo, Japan (SPX) Oct 21, 2010 - DuPont Kabushiki Kaisha and Fujipream Corporation have successfully developed a new thin crystalline silicon (c-Si) glass-glass photovoltaic module

Second-Generation Photovoltaics: Thin-Film Technologies

Jun 13, 2023 · The thin-film technologies are a direct answer to the monopoly of silicon materials in the PV market. With the silicon manufacturing processes being refined as art, the

Flexible silicon solar cells with high power-to-weight ratios

Jan 31, 2024 · A study reports a combination of processing, optimization and low-damage deposition methods for the production of silicon heterojunction solar cells

Crystalline Silicon Photovoltaic Glass Market Transformation

May 21, 2025 · Crystalline Silicon Photovoltaic Glass Market size was valued at USD 3.45 Billion in 2024 and is forecasted to grow at a CAGR of 7.

Crystalline Silicon Photovoltaic Cells and Modules from

Sep 25, 2024 · 102 Crystalline Silicon Photovoltaic Products From the People''s Republic of China and Taiwan: Continuation of Antidumping and Countervailing Duty Orders on China and the

6 FAQs about [Crystalline silicon thin film glass photovoltaic innovation products]

What is thin-film crystalline silicon on glass (CSG)?

Thin-film Crystalline Silicon on Glass (CSG) is a new photovoltaic (PV) technology that uses a very thin layer of a silicon material to fabricate solar cells supported by a cheap transparent glass substrate.

What is crystalline silicon photovoltaics?

Crystalline silicon photovoltaics is the most widely used photovoltaic technology. Crystalline silicon photovoltaics are modules built using crystalline silicon solar cells (c-Si). These have high efficiency, making crystalline silicon photovoltaics an interesting technology where space is at a premium.

Is thin film PV Manufacturing a viable alternative to crystalline-Si?

Thin film PV manufacturing could be initiated rapidly, even in the developing world and emerging PV markets. In most cases, there is not competing crystalline-Si manufacturing. The feedstocks and supply chains for these technologies can be easier to supply in many regions.

Can thin-film silicon absorbers save energy compared to full-silicon-wafer technology?

Alternatively, thin-film multicrystalline (mc) silicon on glass can help to save both energy and material consumption compared to full-silicon-wafer technologies. Competitive PV conversion efficiencies can be expected on thin-film silicon absorbers (10 – 15 µm) using a photonic-crystal light-trapping structure.

Do amorphous silicon-based thin film solar cells outperform conventional monocrystalline solar?

Amorphous silicon-based thin film solar cells with a band gap of 1.8 eV outperform conventional traditional monocrystalline silicon PV by more than 20–25% under water .

Can thin-film solar cells lead to a net-zero carbon future?

Selected notable patents are listed at the end. The objective is to draw attention to the inventions, innovations, and new technologies that thin-film PV could impact, leading to a net-zero carbon future. Thin film solar cells shared some common origins with crystalline Si for space power in the 1950s .

Update Information

- Kuwait New Energy Photovoltaic Power Generation Glass Crystalline Silicon

- Albania crystalline silicon photovoltaic module prices

- How much does a square meter of photovoltaic glass semi-finished products cost

- Phosphorus silicon glass layer photovoltaic

- N-type 580wp crystalline silicon photovoltaic module price

- Bulgarian thin film photovoltaic module glass

- Advantages and disadvantages of crystalline silicon photovoltaic curtain wall

- Dominica crystalline silicon photovoltaic panel manufacturer

- Comoros crystalline silicon photovoltaic panel prices

- Photovoltaic glass component companies

- Photovoltaic curtain wall glass supplier

- Does photovoltaic glass have any content

- Georgia Photovoltaic Glass Processing Plant

Solar Storage Container Market Growth

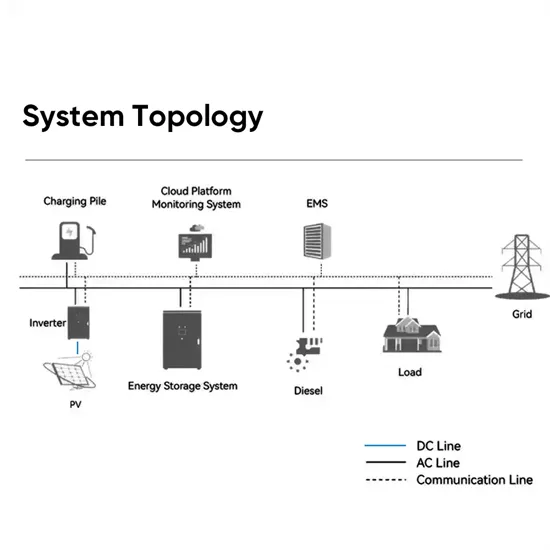

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.