ESS Battery Cell Performance Testing Cabinet

Brief Description The ESS Battery Cell Performance Testing Cabinet is a high-precision system designed to evaluate the electrical and thermal performance of energy storage system (ESS)

General overview on test standards for Li-ion batteries,

Nov 2, 2017 · This table covers test standards for Li-ion batteries. It is made in the European projects eCaiman, Spicy and Naiades. batterystandards

Stationary Battery String TestingUsing Infrared

Jan 10, 2023 · Introduction To understand how thermography as a predictive maintenance tool applies to testing of stationary battery applications, it is important to understand the overall

DFT-6102 Battery Conductance Tester Users Manual

Jul 22, 2022 · Chapter 1 Overview 1.1. Purpose The battery Conductance Tester adopts the most advanced AC discharge test method, which can accurately test en judge the advantages and

Battery Cabinet Testing Procedures | We Group E-Site

A 2023 DNV report revealed that battery cabinet testing procedures fail to detect 12% of thermal runaway risks in commercial installations. This gap directly correlates with the 27% year-on

Realistic Drive Cycle-Based Testing Methodology for Batteries

Dec 4, 2024 · This paper presents a battery testing methodology for integrated starter and generator applications in micro hybrid electric vehicles. Instead of requiring an actual vehicle

Battery Conductance & How to Apply It

Jun 5, 2021 · Battery conductance is measured by evaluating the voltage response to a small, select frequency AC current signal briefly impressed on the battery. The resultant conductance

How to Design a Simple and Highly Integrated Battery

Apr 1, 2023 · Right now, most battery testing manufacturers use separation solutions to design battery charging and discharging systems. This application report describes how to design an

Battery Conductance Testing Procedures and Maintenance

Nov 11, 2020 · Conductance based battery testing combined with a simple utility load test provides the technician the necessary information needed to optimize the financial investment

Conductance Testing for VRLA Batteries

Jan 6, 2021 · A: The original technology was developed by Motorola in the 1970s for testing automotive batteries. Today''s products are manufactured under license from Motorola, and

Recent Progress on the Air-Stable Battery Materials for Solid

In summary, the air stability of battery materials is a critical issue during the fabrication of solid-state batteries and can be enhanced using surface coating., and the exploration of novel

Conductance Testing as an Integral Element in Battery

Nov 11, 2020 · Conductance Testing Conductance measurements, sometimes called acceptance measurements, are performed by applying an AC voltage of a known frequency and amplitude

Reference Value Quick Tips Battery Conductance Training

May 17, 2021 · While a conductance test provides a reliable, eficient and efective method for evaluat-ing battery state-of-health, conductance data can not be directly correlated to a

Choosing the Right Lithium Ion Battery Cabinet: A Complete

May 1, 2025 · Ensure maximum safety and efficiency with this in-depth guide on selecting a lithium ion battery cabinet. Learn key features, regulations, and storage solutions to protect

6 FAQs about [Battery cabinet conduction sensitivity test]

What is a battery conductance test?

Without running extensive discharge tests, conductance can be used to rapidly and safely determine a functional battery’s state-of-health. Together with other battery information, conductance can also be used to detect cell defects, shorts, and open circuits which can cause early battery failure.

Do you need a battery conductance tester?

NFPA 110, 8.3.6.1 “Battery conductance testing shall be permitted in lieu of the testing of specific gravity when applicable or warranted.” With the battery conductance tester, personnel can save time and money with more accurate results, quickly identify battery health, and uncover potential problems before an actual emergency.

What is battery conductance?

It provides a direct relationship to battery power parameters. Battery conductance is measured by evaluating the voltage response to a small, select frequency AC current signal briefly impressed on the battery. The resultant conductance measurement provides pertinent battery information without the need of bringing the battery to full discharge.

What is a conductance test?

Conductance test measurements become a valuable tool to identify the point at which the battery is approaching its end of service life. There is no direct correlation between conductance and the available capacity from a battery; hence a coefficient does not exist. As remaining battery life decreases, so does the conductance.

Why is a battery conductance measurement important?

The resultant conductance measurement provides pertinent battery information without the need of bringing the battery to full discharge. As a battery discharges, its conductance and capacity are reduced with a simultaneous drop in power in a predictable manner due to the depletion of conductive active materials.

How do you determine a battery's conductance?

Initial conductance value for the most batteries can be provided by the battery manufacturer. If the batteries conductance value is not available it can be reasonably established by using the average of 20 to 30 measured conductance values provided they are the same type of battery, date code and state of charge.

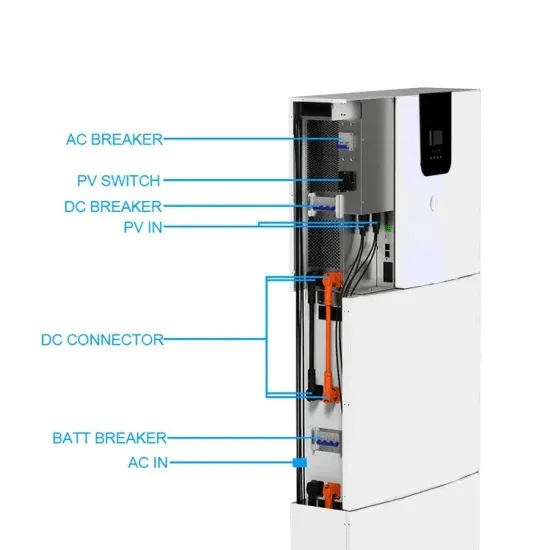

Update Information

- Battery cabinet self-discharge test

- Battery cabinet DC internal resistance test system

- Battery cabinet storage capacity test

- Lithium battery station cabinet reliability test items

- Civilian battery cabinet test

- How much current does the energy storage cabinet battery output

- Energy Storage Battery Cabinet Standard

- Battery cabinet market trend base station

- The middle line of the two battery cabinet batteries

- Substation AC battery cabinet alarm

- Is the battery in the energy storage cabinet very powerful

- Abuja outdoor communication battery cabinet

- New lithium battery energy storage cabinet equipment

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.