Understanding Battery Internal Resistance Testing: A

Nov 27, 2024 · To test DC resistance, a DC electronic load tester equipped with battery internal resistance measurement capabilities is required. These testers are designed to apply a

A measurement method for determination of dc internal resistance

Feb 1, 2010 · Abstract Internal resistance is an importance parameter determining the power performance of a battery or supercapacitor. An 8.5 Ah Li-ion battery and a 350 F

What is Battery Internal Resistance?

Feb 1, 2025 · Battery internal resistance is the opposition to the flow of current within a battery, caused by its chemical composition, electrode materials, and design. High internal resistance

Internal Ohmic Measurement vs. Capacity Testing – 4 Key

Dec 18, 2024 · Internal ohmic measurement provides insight into the battery''s internal condition and resistance, while capacity testing assesses its ability to store and deliver energy.

Precision Battery Test Racks for Cell Capacity & Internal Resistance

Jul 5, 2025 · Optimize your battery testing with precision test racks for accurate cell capacity and internal resistance measurement. Ensure reliable performance and quality!

Microsoft Word

Apr 30, 2012 · DataSafe® HX Front Terminal Battery Cabinets are shipped partially assembled, internally pre-wired and come standard with a circuit breaker for over current protection. Each

How to calculate the internal resistance of the battery

What is battery internal resistance? Battery internal resistance is a crucial parameter that determines the performance and efficiency of a battery. It is the measure of opposition to the

Battery Internal Resistance Test: A Crucial Tool In Battery

Jun 28, 2023 · The principle of DC internal resistance testing is to calculate the DC internal resistance of a battery by applying a high current (charging or discharging) to the battery or

AC Discharge Internal Resistance Measurement

Dec 26, 2022 · Abstract: This article introduces battery online monitoring and condition evaluation, analyzes battery internal resistance and its influencing

How to calculate the internal resistance of the battery

The DC load test is a simple and widely used method for measuring battery internal resistance. It involves applying a known load to the battery and measuring the voltage drop across the

EOL Test Cabinet for Battery Capacity, Internal Resistance,

Ensure the reliability of your batteries with our EOL Test Cabinet, designed for comprehensive testing of battery capacity, internal resistance, and insulation performance.

Four common methods for detecting internal resistance in battery

You can choose functions such as internal resistance testing, voltage testing, and capacity estimation for the battery according to your own situation. For example, some professional

DC internal resistance during charge: Analysis and study on

Nov 20, 2013 · DC internal resistance (IR) is considered one of the most important parameters of a battery, as it is used to evaluate the battery''s power performance, energy efficiency, aging

DC internal resistance test(BTS)

Nov 14, 2024 · DCIR test is the DC internal resistance test, which refers to the ratio of the battery voltage change to the corresponding discharge current change under working conditions.

化学电源内阻测量及状态监测策略分析研究

Apr 1, 2024 · These advancements are expected to significantly enhance the accuracy of the internal resistance measurement in chemical power systems,

6 FAQs about [Battery cabinet DC internal resistance test system]

How to measure internal resistance of a battery?

One can mention the IEC 61960 standard or PNGV (Partnership for a New Generation of Vehicles) procedure for example. Measurement methods for the internal resistance of batteries can be divided up into two categories: DC (Direct Current) techniques and AC (Alternating Current) techniques.

What is internal resistance testing?

Internal resistance testing is carried out at each process after battery cells are filled with electrolyte and their assembly completed (charge/discharge testing, aging testing, shipping inspections, etc.). There are two methods for measuring internal resistance: the AC method (AC-IR) and the DC method (DC-IR).

Which battery testers are used in internal resistance testing?

Hioki’s battery testers are working at battery manufacturers around the world. The following models are used in internal resistance testing in battery cell production processes. *1: Available to convert the 4-terminal pair measurement of BT4560 to 4-terminal measurement with the conversion plug. *3: Special specification of 0.01 Hz to 10 kHz.

How do you measure DC resistance in a battery?

According to IEC61960, t he DC resistance can be measured as follows: A DC current step is applied to measure the change in the cell’s voltage. Battery resistance is defined as the change in voltage over the change in current when a discharge current of 0.2C is applied for 10s followed by a discharge current of 1C for 1s.

What is battery resistance?

Battery resistance is defined as the change in voltage over the change in current when a discharge current of 0.2C is applied for 10s followed by a discharge current of 1C for 1s. The DCIR is calculated by

Is ACIR a good method for evaluating batteries' internal resistance?

Nonetheless, it is a highly effective method of evaluating batteries’ internal resistance. Such an experiment is very easy to set up with BioLogic potentiostats and battery cyclers thanks to the ACIR (Alternating Current Internal Resistance) techniques included in EC-Lab and BT-Lab, BioLogic’s benchmark control and analysis software.

Update Information

- Iraq DC screen battery cabinet equipment

- Guinea-Bissau DC screen battery cabinet price

- Powerful supplier of DC panel battery cabinet

- DC screen battery cabinet installation

- Is the DC 212V battery cabinet normal

- New Energy Battery Cabinet Pre-charge Resistance

- GZDW DC battery cabinet battery is out of power

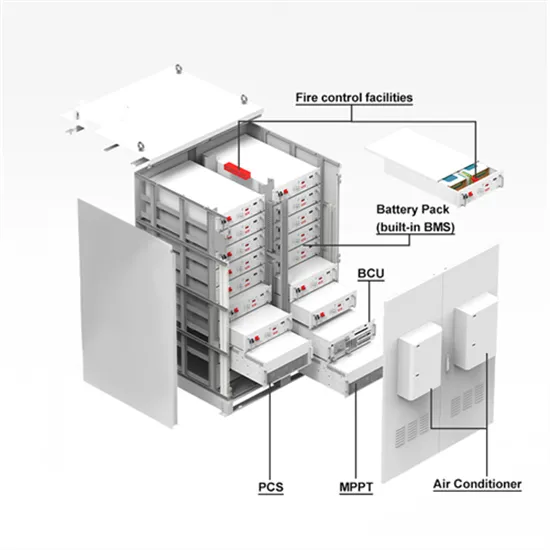

- Internal composition of new energy battery cabinet

- Minsk DC screen battery cabinet manufacturer direct sales

- Battery cabinet self-discharge test

- Selection of DC circuit breaker for UPS battery cabinet

- Site Energy Battery Cabinet Free Agent

- Fully automatic lithium battery station cabinet production line

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.