Maintenance BestPractices & Intervals for Substation

Oct 24, 2017 · Maintenance BestPractices & Intervals for Substation Equipment Presented by: Paul Schlies, President/CEO Energis High Voltage Services, Inc.

Gas Detection for Battery Rooms

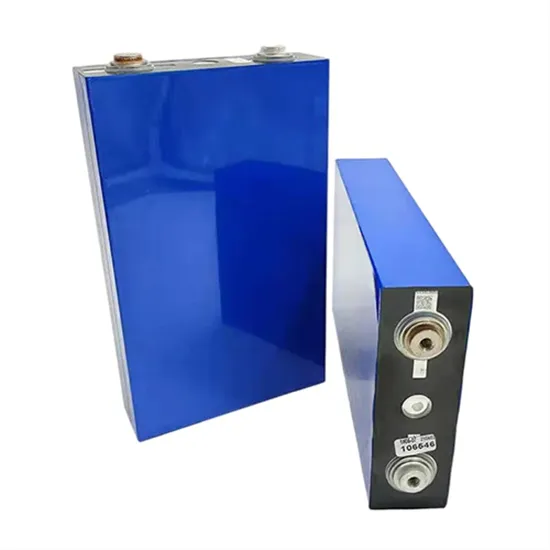

Nov 8, 2024 · The batteries used for battery backup and energy storage are typically either lead-acid, lithium-ion or hydrogen-based. Each battery type presents its own unique gas threats so

Batteries and Battery Chargers in Major Substations

Jun 6, 2024 · Design Criteria - Batteries Design philosophy to ensure sufficient capacity to make safe substation on loss of AC supply. In addition the ability to supply high current transient

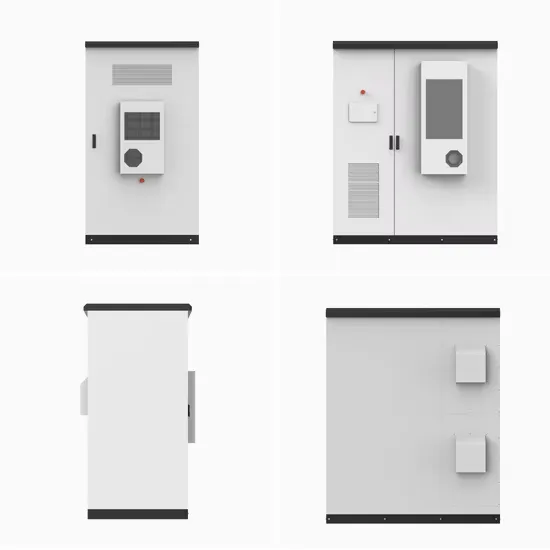

Turnkey Substation Control Centers

All units are pre-assembled, providing significant cost savings over field assembled methods. AC panelboards and AC distribution wiring DC panelboards and DC distribution wiring DC battery

Substation Battery Systems Present & Future

Apr 29, 2024 · The substation batteries for the DC system must be in operation 24/7 – 365 – NOT just for backup power, but also to provide the current needed for day-to-day switching operations

Substation Monitoring System to Troubleshoot Alarms

May 7, 2025 · The manufacturer installed a dataTaker DT80 Intelligent Data Logger in the substation''s control room cabinet which was then connected to sensors on the incoming main

BA300 Battery Monitoring and Alarm | GE Vernova

BA300 monitors the performance of the DC system, which is fundamental to safe, reliable and efficient substation operation. Constant surveillance of battery condition The BA300 provides

Auxiliary DC Control Power System Design for Substations

Feb 7, 2007 · at make up the auxiliary dc control system are required. Many references for stationary battery sys-tem design address only a specific battery technology, making it difficult

BA300 Battery Monitoring and Alarm | GE Vernova

BA300 monitors the performance of the DC system, which is fundamental to safe, reliable and efficient substation operation. Constant surveillance of battery condition. The BA300 provides

The optimal design of Soccer Robot Control System

Introduction The AC/DC integrated power supply of substation consists of the substation AC power supply, DC operational power supply, UPS and communication power supply, etc.

Understanding Substation Batteries: Types, Functions, and

Aug 19, 2025 · Discover the essential role of substation batteries in power systems. Learn about different types, their functions, and why robust battery backup systems are vital for ensuring

DC Battery Rack Grounding

Jul 18, 2017 · In my years as a substation electrician we never grounded battery racks. All substations I''m familiar with have ungrounded DC because a ground fault on either polarity will

What Are Substation Batteries Used For?

Substation batteries provide backup power for critical systems like protective relays, circuit breakers, and communication equipment during grid outages. They ensure grid stability,

Fundamentals of Modern Electrical Substations

Mar 16, 2023 · Part 1 of this course series is concentrated on demonstrating how modern power systems are arranged to accomplish all these goals; what place electrical substations have in

110V DC Substation Battery & Charger Panel

The 110V DC Substation Battery & Charger Panel is a robust power distribution solution designed for industrial and commercial applications. Constructed from durable metal (steel) with a glass

Applied Research on AC/DC Integrated Power Supply of

Oct 30, 2023 · It is equipped with the ATS for automatic transfer between the two AC incomer power supplies to ensure AC output distribution and long-term stable operation of AC/DC

What are the functions of the substation battery cabinet

What is a substation battery system? The primary role of the substation battery system is to provide a source of energy that is independent of the primary ac supply,so that in the event of

Auxiliary DC Control Power System Design for Substations

at make up the auxiliary dc control system are required. Many references for stationary battery sys-tem design address only a specific battery technology, making it difficult to compare

Substation Auxiliary Systems | SpringerLink

Jul 21, 2018 · Substation secondary equipment provides the interface to facilitate functional control, protection, and supervision of the primary plant and indeed the overall power system

Systems for supervision of substation batteries Sy

Aug 22, 2008 · In [5, 6] various devices for measuring the battery impedance as the criterion for supervision battery circuit connectivity are offered, but in [7] it is shown that the conventional

Online Monitoring System for Storage Battery in Substation

Apr 17, 2022 · As the dc power, the battery in substation is the key equipment for safe power supply. When ac power failure occurs in substation, the failure of the battery wi.

6 FAQs about [Substation AC battery cabinet alarm]

What is a substation alarm manager?

Substation Alarm Manager (SAM) was developed in order to provide power utilities with a simple way to show the current status and data within a substation. The SAM Substation Annunciator utilizes our extensive protocol library and allows for a wide variety of substation equipment to be monitored.

What is a substation battery monitoring system?

A substation battery monitoring system is a technological solution designed to oversee the performance and health of batteries within an electrical substation. It monitors and provides crucial data that aids in the management of these batteries, thus ensuring their optimum performance and prolonging their lifespan.

Why do substation batteries need a DC supply?

Many substation battery installations are not only required to provide a DC supply for protection and control equipment, but also to provide trip and close currents to breakers during trip conditions. BA300 monitoring the performance of the DC system is fundamental to the safe, reliable and efficient operation of the substation.

What are the benefits of a substation battery monitoring system?

One of the primary benefits of a substation battery monitoring system is its role in maintaining a continuous power supply. By identifying and reporting potential battery issues before they escalate into failures, these systems prevent unexpected power outages, ensuring the uninterrupted delivery of electricity to consumers.

What is ASE substation alarm manager?

ASE Substation Alarm Manager (SAM) provides power utilities with a simple way to display the current status and data within a substation. SAM Substation Annunciator utilizes our extensive protocol library and enables a wide variety of substation equipment to be monitored.

Where do batteries go in a substation?

In large substations, the batteries may be out in the middle of the floor with the pan protruding all the way around the battery rack. Erroneously, the measurements for the required working space about the batteries are many times taken from the terminals of the batteries.

Update Information

- Substation battery cabinet

- How to discharge the battery cabinet in the substation quickly

- Battery cabinet alarm

- Liechtenstein UPS dedicated battery cabinet

- Solar Storage Battery Cabinet Base Station

- Zambia Bay Battery Cabinet Project

- What type of battery is the energy storage cabinet battery called

- Is there a battery cabinet factory in Baghdad

- Which brand of battery cabinet is better in Abu Dhabi

- Telecom site lithium battery pack 12v battery cabinet

- China s top ten battery cabinet brands

- Battery cabinet continuous current

- Industrial Park Photovoltaic Energy Storage Battery Cabinet

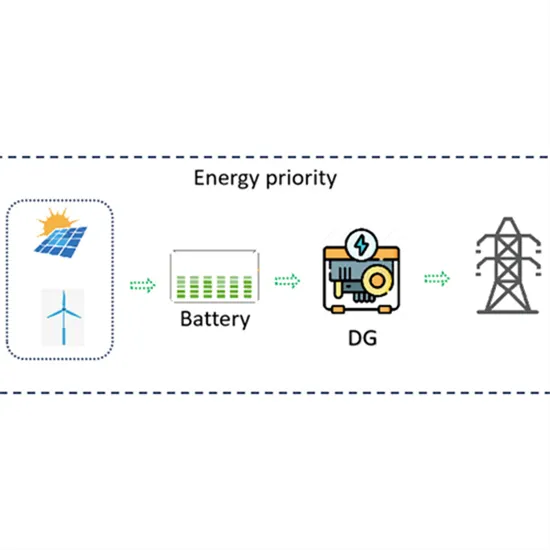

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.