Chad Lithium Iron Phosphate Batteries Market (2025-2031

The Chad lithium iron phosphate (LiFePO4) batteries market is influenced by the growing demand for high safety, long-life, and stable batteries. LiFePO4 batteries are used in various

Chad Phosphorus Chemical Lithium Battery Project

A new composite lithium-ion battery anode made of black phosphorus-graphite particles (black) coated with a polyaniline (blue) could enable high-capacity, fast-charging batteries.

Battery Comparison: NiMH vs Li-ion vs LiFePO4 – Which Battery

Apr 22, 2025 · Whether you''re powering a smartphone, a remote-control toy, or an electric vehicle, the type of battery inside can significantly impact efficiency, lifespan, and safety. In this

Lithium iron phosphate or lithium ion battery, which decays fast

The design of the lithium iron phosphate battery pack is different. It is not the same as the ternary lithium ion battery pack. The single cell is installed in a separate installation mode, which also

Chad Lithium Iron Phosphate Battery Market (2025-2031)

Market Forecast By Voltage Range (3.2 KV, 3.2"12 KV, 12"20 KV, Above 20 KV), By Application (Electric Vehicles, Energy Storage Systems, Industrial Equipment, Telecommunications), By

5 facts about LFP chemistry for electric vehicle

Sep 22, 2022 · Lithium iron phosphate batteries first came to light in 1996, so it''s not surprising this battery chemistry is already present in the electric vehicle

What kind of power batteries are available for lithium iron phosphate

The cathode materials of lithium batteries mainly include lithium cobalt oxide, lithium manganate, lithium nickelate, ternary materials, lithium iron phosphate, and so on.

Ternary lithium batteries (NCM) VS lithium iron

Nov 19, 2020 · 6. In terms of cycle life, lithium iron phosphate batteries are better than ternary lithium batteries. The theoretical life of ternary lithium batteries is

LiFePO4 VS. Li-ion VS. Li-Po Battery Complete

Mar 18, 2024 · Among the many battery options on the market today, three stand out: lithium iron phosphate (LiFePO4), lithium ion (Li-Ion) and lithium polymer

Ternary lithium battery or lithium iron phosphate battery

Dec 23, 2021 · At present, there are two mainstream battery technology routes for new energy vehicles, lithium iron phosphate batteries and ternary lithium batteries. To this end, we take

Effect of fast charging on degradation and safety

Jan 1, 2025 · Lithium iron phosphate (LiFePO4, or LFP) is a pivotal cathode material in state-of-the-art EV batteries due to the merits of high thermal stability, long cycle lifetime, and high

Past and Present of LiFePO4: From Fundamental Research to

Jan 10, 2019 · In this overview, we go over the past and present of lithium iron phosphate (LFP) as a successful case of technology transfer from the research bench to commercialization. The

Investigation on Over-charging Characteristics of

Jan 23, 2025 · The over-charging experiments conducted on three brands of lithium iron phosphate batteries have demonstrated that serious damages with a swelling end, an opening

Lithium Iron Phosphate Battery Pack with Built-in Chad | Ubuy

Shop online for high-quality 100ah, 150ah, and 200ah lithium iron phosphate (LiFePO4) battery packs with built-in BMS at Ubuy Chad. Perfect for golf carts, campers, and solar energy

Chad 100kWh Energy Storage System – GSL Energy''s Advanced Lithium

Apr 28, 2025 · In Chad, we successfully installed a 100kWh energy storage system for a local customer. The system consists of 20 5kWh wall-mounted lithium iron phosphate batteries,

LiFePO4 Battery Technology for 12V Energy Storage

Mar 20, 2025 · Explore the benefits of Lithium Iron Phosphate (LiFePO4) battery technology for 12V energy storage. Learn how these batteries offer long lifespan, efficiency, and safety for

Complete Guide to LiFePO4 Battery Charging

Jul 23, 2025 · The positive electrode material of lithium iron phosphate batteries is generally called lithium iron phosphate, and the negative electrode material is

Lithium iron phosphate battery decays over a few years

Do lithium iron phosphate based battery cells degrade during fast charging? To investigate the cycle life capabilities of lithium iron phosphate based battery cells during fast charging,cycle

6 FAQs about [Which lithium iron phosphate battery pack in Chad decays faster]

What are lithium iron phosphate batteries?

In the current energy industry, lithium iron phosphate batteries are becoming more and more popular. These Li-ion cells boast remarkable efficiency, state-of-the-art technology and many other advantages that have been proven to deliver unprecedented power levels for applications.

Is lithium iron phosphate a successful case of Technology Transfer?

In this overview, we go over the past and present of lithium iron phosphate (LFP) as a successful case of technology transfer from the research bench to commercialization. The evolution of LFP technologies provides valuable guidelines for further improvement of LFP batteries and the rational design of next-generation batteries.

What is the difference between lithium iron phosphate and ternary lithium batteries?

Although lithium iron phosphate batteries are resistant to high temperatures, ternary lithium batteries have better low-temperature resistance and are the main technical route for manufacturing low-temperature lithium batteries. At minus 20°C, ternary lithium batteries can release 70.14% of their capacity.

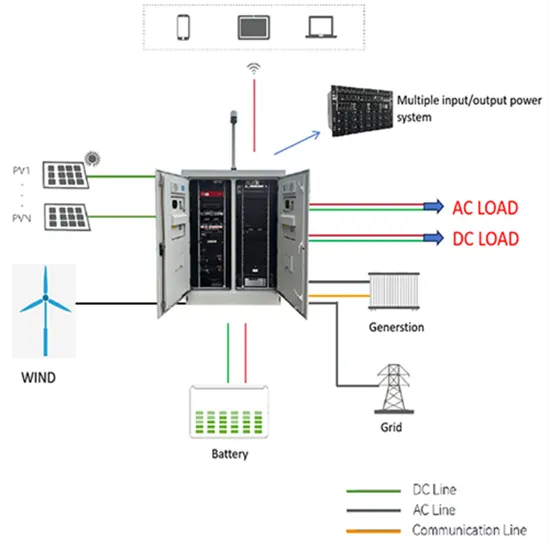

What is a lithium iron phosphate battery energy storage system?

The lithium iron phosphate battery energy storage system consists of a lithium iron phosphate battery pack, a battery management system (Battery Management System, BMS), a converter device (rectifier, inverter), a central monitoring system, and a transformer.

What are the advantages of lithium iron phosphate battery?

Lithium iron phosphate battery has a series of unique advantages such as high working voltage, high energy density, long cycle life, green environmental protection, etc., and supports stepless expansion, and can store large-scale electric energy after forming an energy storage system.

Why is lithium iron phosphate (LFP) important?

The evolution of LFP technologies provides valuable guidelines for further improvement of LFP batteries and the rational design of next-generation batteries. As an emerging industry, lithium iron phosphate (LiFePO 4, LFP) has been widely used in commercial electric vehicles (EVs) and energy storage systems for the smart grid, especially in China.

Update Information

- Lithium iron phosphate battery pack product introduction

- 144v lithium iron phosphate battery pack

- 12V 3-channel 4-channel lithium iron phosphate battery pack

- Cook Islands lithium iron phosphate battery pack

- 41kw lithium iron phosphate battery pack

- Backup energy storage lithium iron phosphate battery pack

- 500ha lithium iron phosphate battery pack price

- Production of lithium iron phosphate battery pack

- El Salvador lithium iron phosphate battery pack

- Rechargeable lithium iron phosphate battery pack

- Which Congo lithium battery pack is better

- Lithium iron phosphate single 12v energy storage battery

- 8 groups of lithium iron phosphate battery packs connected in series

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.