How to Maintain Backup Power Supply for Telecommunications Base Stations?

Battery Maintenance: If the backup power system includes batteries, perform regular maintenance tasks such as checking electrolyte levels (for flooded lead-acid batteries), cleaning terminals,

Maintenance of communication base station power supply

This article discusses how to improve the power supply safety of the power supply system of communication base stations, reduce the failure rate of the power supply system of

Communication base station battery maintenance equipment

Mar 12, 2019 · The recording and processing requirements of the base station battery test data, the accumulation of these data, can create a complete battery file, providing a credible basis

Testing and Checking of GMDSS Batteries Required by SOLAS

Nov 7, 2023 · During the commissioning phase, this checklist provides a safe, consistent method for the initial inspection, checkout, testing, & data

Maintaining connectivity with load-bank tested backup batteries

Apr 12, 2024 · A load bank is a piece of electrical test equipment capable of testing power sources by simulating loads. Frequently used to check generator performance, load banks can also

Base Station Components | Radio Comms Warehouse

The NOVA range of power supplies is the most extensive by far. Each unit has been developed over the years incorporating value added features such as metering and adjustable voltage.

How to Troubleshoot the Power Supply Unit (PSU) of a Dell

Jul 24, 2025 · Learn how to identify if the power supply unit of a Dell desktop is working. Find steps to troubleshoot issues with power supply units and running a self-test diagnostic on the

Backup Battery Analysis and Allocation against Power

Jun 1, 2018 · Through exploiting the correlations between the battery working conditions and battery statuses, we build up a deep learning based model to estimate the remaining lifetime

Base Station Power Supply | We Group E-Site

The Silent Backbone of Modern Connectivity Have you ever wondered what keeps your 5G signals flowing during a storm? Behind every seamless video call lies a base station power

Main Causes of Shortened Battery Lifespan in Base Stations

Battery packs are a crucial part of the base station''s DC uninterruptible power supply, with investments comparable to those in switch power supply equipment. Most mobile base

Mobile base station site as a virtual power plant for grid

Mar 1, 2025 · Furthermore, it seeks to determine if the full activation time can meet the requirements of an FFR product. The system consists of a live mobile base station site with a

Daily maintenance and management of base station power supply

This post was last edited by jameswangsynnex on 2015-3-3 20:00 Batteries are an important part of the base station power system. The stability of their operation is directly related to the

Base station battery discharge test method

Notable discharge testing methods include load bank testing,capacity testing,partial discharge,and charge/discharge cycle testing. The first one is load bank testing. It is the most comprehensive

Maintenance Points for Telecom Base Station Batteries

(8) Battery capacity testing and discharge testing should be performed regularly. ① A verification discharge test should be done every year, discharging 30% to 40% of the rated capacity. ②It

Base station battery charging and discharging test

Among all the tests, the discharge test (also known as load test or capacity test) is the only test that can accurately measure the true capacity of a battery system and in turn determine the

Optimal configuration of 5G base station energy storage

Feb 1, 2022 · The high-energy consumption and high construction density of 5G base stations have greatly increased the demand for backup energy storage batteries. To maximize overall

What is the purpose of batteries at telecom base

Feb 10, 2025 · Among the many types of batteries, why can lead-acid batteries become the first choice for telecom base stations? This is mainly due to its

Power Supply Testing | Keysight

Mar 1, 2024 · Power Supply Testing As regulated-power supply technology evolves, testing methods for design verification and product function require more sophisticated electronic

6 FAQs about [How to test the battery of base station power supply]

What is a battery capacity test?

Annual capacity test that measures the capacity of the battery in Ampere hours. The battery should be replaced if its capacity is less than 80% of the rated capacity. 3. General maintenance - measuring of the electrolyte level and the specific gravity. Let's consider each of them in detail. By this test we can ensure that:

What are the different types of battery test?

There are three types of tests: 1. Daily on load/off load test, which ensures that all connections are intact and the voltage on loaded batteries do not drop too quickly. 2. Annual capacity test that measures the capacity of the battery in Ampere hours. The battery should be replaced if its capacity is less than 80% of the rated capacity. 3.

What is battery testing?

Battery testing comprises measuring the voltage, capacity, & other parameters of the battery with the help of a multimeter or another equipment. You will be able to tell whether a battery is defective, weak, or needs to be changed based on the results of the tests performed on the battery. What is the purpose of Battery Testing?

How do you test a battery?

Battery testing in accordance with multiple standards, including IEC 62619. The initial stage is a visual inspection. Check the cell (or) battery. Examine it for signs of damage, such as leaks, cracks, rust, or swelling. You may also need to smell the rechargeable battery. A leaky cell usually smells appealing.

How long should a battery last after a capacity test?

After the capacity test, the measurement of the time a battery charges up to 100% should be done. Under SOLAS requirements this time should be less than 10 hours. The onboard batteries require no great maintenance. Just 2 parameters should be checked: the electrolyte level and the specific gravity of the electrolyte.

How to test GMDSS battery?

1. Disconnect the GMDSS station from the AC power supply by pressing the on/off button on the GMDSS panel (or in the radio room). Switch off all other power sources that charge the battery, if any. If the battery is being continuously charged, we will see no voltage drop. But by means of this test we intend to determine exactly the voltage drop.

Update Information

- How much is the Caracas BESS outdoor base station power supply

- How to configure the base station power supply

- How much does it cost to change the power supply of Damascus 5g base station

- How to calculate the base station power supply current

- How much does the power supply cost for a communication base station

- How much is the photovoltaic power generation power of the lead-acid battery of the Ottawa communication base station

- Battery power supply alarm for communication base station

- Sierra Leone 5g base station battery power supply

- How to connect the high frequency power supply of the base station

- Uninterruptible power supply battery for communication base station is small

- How to calculate the battery power of base station

- How much power does the battery energy storage system of a building communication base station generally have

- How many seats are there in the Belgrade communication base station uninterrupted power supply

Solar Storage Container Market Growth

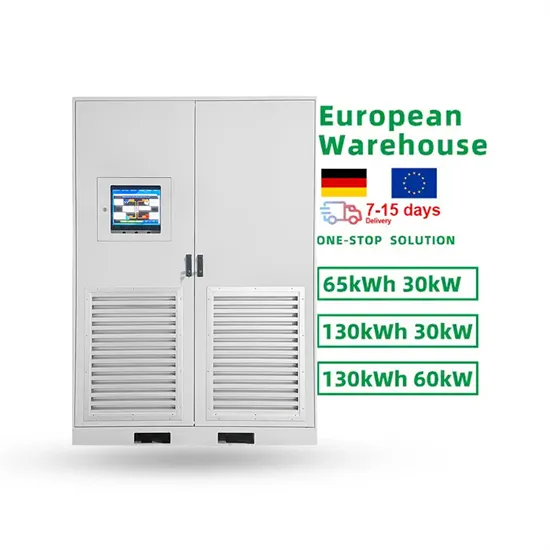

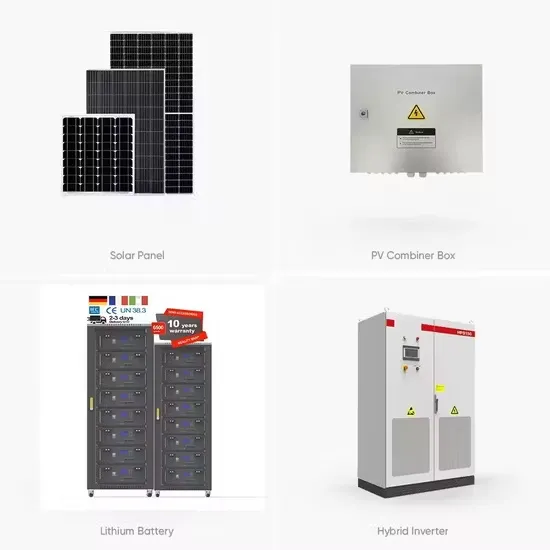

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.