Ensure Your Base Station Transmitter Complies with 5G

Dec 8, 2023 · Base stations must now pass new conformance tests to ensure they deliver on their promises. Performing conformance testing is an important part of the base station lifecycle,

UPS Battery Backup Time Calculator

Oct 3, 2024 · Understanding the backup time of a UPS (Uninterruptible Power Supply) is crucial for maintaining power to critical devices during a power outage. This measure helps in

How to Determine the Right Battery Capacity for Telecom Base Stations

Mar 10, 2025 · Power Consumption: Determine the base station''s load (in watts). Backup Duration: Identify the required backup time (hours). Battery Voltage: Select the correct voltage

Optimal configuration of 5G base station energy storage

Feb 1, 2022 · The high-energy consumption and high construction density of 5G base stations have greatly increased the demand for backup energy storage batteries. To maximize overall

Performance Analysis of VRLA Battery for DC Load at

Mar 5, 2022 · Abstract –The high level of power outage in Sukabumi-Cianjur area has influenced the operations of telecommunication industry in the vicinity. This has shortened the battery life

How to Calculate the Required Battery Capacity

Jan 14, 2025 · This article will provide a scientific method for calculating the required battery capacity and guide users on how to select the right power station based on actual electricity

Battery Sizing Considerations IEEE 2020

Mar 11, 2020 · The Battery''s Purpose Batteries provide DC power to the switchgear equipment during an outage. Best practice is to have individual batteries for each load/application.

Optimum sizing and configuration of electrical system for

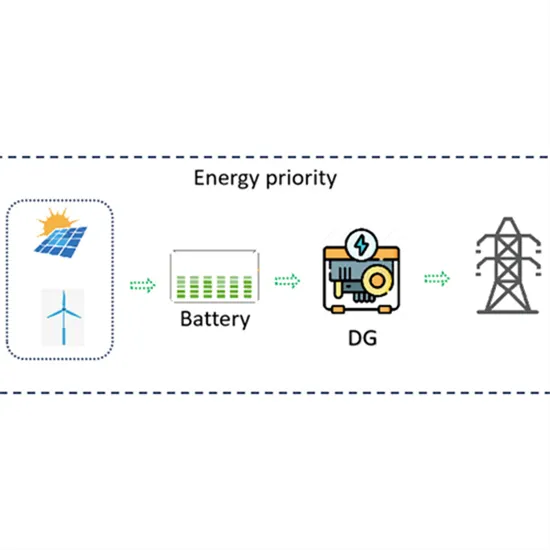

Jul 1, 2025 · Proposed a model for optimal sizing & resources dispatch for telecom base stations. The objective is to achieve 100% power availability while minimizing the cost. Results were

Battery Pack Calculator | Good Calculators

Here''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and maximum discharge

What Size Battery for Base Station? | We Group E-Site

When designing base station power systems, engineers face a critical dilemma: How do we balance battery capacity with operational realities? Recent GSMA data reveals that 23% of

Backup Battery Analysis and Allocation against Power

Jan 17, 2022 · Through exploiting the correlations between the battery working conditions and battery statuses, we build up a deep learning based model to estimate the remaining lifetime

Power consumption modeling of different base station types

Mar 3, 2011 · In this paper we developed such power models for macro and micro base stations relying on data sheets of several GSM and UMTS base stations with focus on component

How to Calculate the Right Battery Capacity for Your

Nov 3, 2023 · To find the energy consumption, multiply the power requirement by the desired runtime. Energy is measured in watt-hours (Wh) and is a key metric in determining battery

Onlin free battery calculator for any kind of battery

Battery calculator : calculation of battery pack capacity, c-rate, run-time, charge and discharge current Onlin free battery calculator for any kind of battery : lithium, Alkaline, LiPo, Li-ION,

Matching calculation method of 5g base station power supply

Jun 12, 2025 · One base station is configured with one operator''s three cells (1 BBU + 3 AAU). Assuming that the power consumption of 5g BBU is 350W and that of AAU is 1100W, relevant

base station energy storage battery capacity calculation rules

How to Calculate Battery kWh In conclusion, unraveling the complexities of Battery kWh calculation empowers individuals and industries to make informed decisions in the evolving

Explanatory note about power system configuration of BTS

Explanatory note about power system configuration of BTS The Base Transceiver Station (BTS) is a telecoms infrastructure to facilitate wireless communication between subscriber device and

6 FAQs about [How to calculate the battery power of base station]

How do you calculate battery capacity?

Formula: Capacity (Ah)=Power (W)×Backup Hours (h)/Battery Voltage (V) Example: If a base station consumes 500W and needs 4 hours of backup at 48V, the required capacity is: 500W×4h/48V=41.67Ah Choosing a battery with a slightly higher capacity ensures reliability under real-world conditions.

How do I choose a base station?

Key Factors: Power Consumption: Determine the base station’s load (in watts). Backup Duration: Identify the required backup time (hours). Battery Voltage: Select the correct voltage based on system design. Efficiency & Discharge Rate: Consider battery efficiency and discharge characteristics.

How to calculate a battery load?

Step 1: Collect the Total Connected Loads The first step is the determination of the total connected loads that the battery needs to supply. This is mostly particular to the battery application like UPS system or solar PV system. Step 2: Develop the Load Profile

How does a battery group work in a base station?

The equipment in base stations is usually supported by the utility grid, where the battery group is installed as the backup power. In case that the utility grid interrupts, the battery discharges to support the communication switching equipment during the period of the power outage.

How much energy can a portable power station store?

Voltage (V) denotes the electrical force, or potential difference, of the battery. Consider a power station with a battery capacity of 50Ah and a voltage of 12V. Using the calculator, the energy capacity would be: Thus, the portable power station can store up to 600 watt-hours of energy.

How is battery size determined?

Battery size is determined by considering factors such as the power demand of the system, desired battery runtime, efficiency of the battery technology, and any specific requirements or constraints of the application. It involves calculating the required energy capacity and selecting a battery with matching specifications.

Update Information

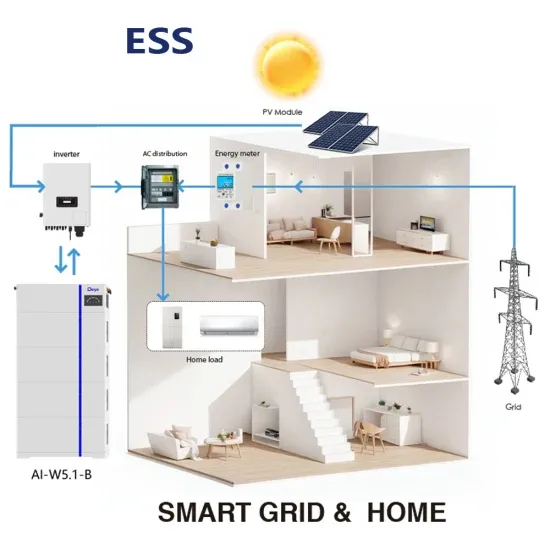

- How to use ESS power base station in battery cabinet display cabinet

- How to connect the bridge to the battery cabinet ESS power base station

- How to calculate the cost of building a base station power supply

- How much power does the battery energy storage system of a building communication base station generally have

- Battery power supply alarm for communication base station

- Nigeria 5g base station battery power supply store

- After the base station is set up how to put the power supply

- Sierra Leone 5g base station battery power supply

- Base station lead-acid battery base station power generation method

- Battery cabinet and distribution cabinet installation ESS power base station

- 5g base station energy storage battery power

- Battery replacement device ESS power base station container

- How many 5G base station photovoltaic power generation system sites are there in Brasilia

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.