How to Use DC to AC Inverter: Examples, Pinouts, and Specs

This circuit is a solar power management system that integrates a solar panel, battery, and inverter to provide a stable 12V DC and 220V AC output. It includes automatic transfer

How to Build a 12v to 230v Inverter Circuit: A Complete

A 12v to 230v inverter circuit is a device that converts 12 volt direct current (DC) power from a battery or other power source into 230 volt alternating current (AC) power, which is the

Inverter, Solar Inverter, Home Power Inverter | inverter

300 watt solar on grid inverter, grid tie inverter, pure sine wave output, converts 12V/24V DC to 120 AC, 48V DC to 230V AC is optional. Grid tie solar inverter with high performance MPPT

How to Build a 12v Inverter Circuit Diagram for Powering

Find the circuit diagram for a 12v inverter and learn how it can convert direct current (DC) to alternating current (AC) for various applications. Understand the components and connections

How to Calculate the Maximum Output Power of a Power Inverter

With home systems from batteries from 12V to 48V, the power inverter will always step up the voltage; thus, the current will be lower at the output of the inverter. With step up inverters, the

How to Build a 12v Inverter Circuit Diagram for Powering

A 12V inverter circuit is commonly used to convert 12V DC (direct current) power from a battery or another power source into 120V AC (alternating current) power. This allows you to power AC

Inverter Current Calculator, Formula, Inverter Calculation

5 days ago · Inverter Current Formula: Inverter current is the electric current drawn by an inverter to supply power to connected loads. The current depends on the power output required by the

Understanding Inverter Input And Output: What

3 days ago · The inverter output is the electrical power generated by the inverter from the process of converting the DC input source into alternating current

12 Volt DC Power Inverter: In-Depth Learning

Mar 31, 2025 · Output Sockets – Provides AC outlets for connecting electrical devices. Safety Features – Built-in overload protection, short-circuit protection,

6 FAQs about [12V inverter AC output]

What is a 12V inverter?

A 12V inverter is an electronic device that converts 12V direct current (DC) power from a battery into 120V alternating current (AC) power. This conversion is necessary when you want to power AC appliances or devices using a DC power source, such as a battery.

What is inverter output?

The inverter output is the electrical power generated by the inverter from the process of converting the DC input source into alternating current (AC).

Why should you use a 12V inverter circuit?

Using a 12V inverter circuit can be a cost-effective solution compared to other alternatives. It eliminates the need for expensive and bulky transformers, as well as the need for separate AC power sources. By utilizing a single 12V input, the circuit can provide AC power efficiently and economically.

What are the components of a 12 volt inverter circuit diagram?

The main components of a 12v inverter circuit diagram include a 12-volt DC power source, a power oscillator, a transformer, and a rectification circuit. The power oscillator generates the required AC waveform, which is then transformed by the transformer into a higher voltage suitable for powering various devices.

Can a 12V inverter be used in a car?

Yes, a 12V inverter circuit can be used in a car. It can be connected to the car’s 12V battery to provide AC power for various devices while on the go. This is especially useful for long road trips or camping trips when you need to power electronic devices that require AC power.

How to build a 12V inverter circuit?

Building a 12V inverter circuit requires a detailed understanding of the components and their connections. In order to create a well-functioning inverter, a circuit diagram is essential. The circuit diagram acts as a visual representation of how different components are connected to convert the 12V DC input into 220V AC output.

Update Information

- How much AC power does the inverter output

- 12v to 48v inverter output 220v

- Inverter rated AC output power

- How to achieve AC output of inverter

- AC inverter 12v to 220v 5KW

- 220v AC to 12v DC connected to inverter

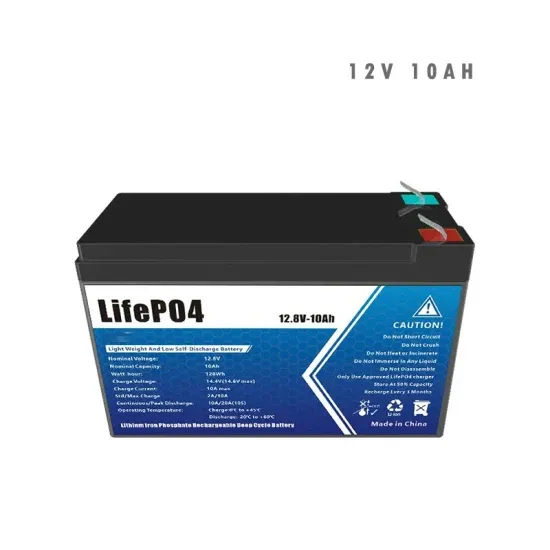

- Inverter 12v lithium iron phosphate battery assembly

- What is the maximum watt inverter that can be used with a 12v 60A lithium battery

- Inverter output AC24V

- Inverter output 20khz sine wave

- Norway Bergen lead-acid lithium battery universal 12v inverter

- AC DC dual-purpose inverter

- Acdc AC DC inverter

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.