How To Make 12v DC to 220v AC Converter/Inverter Circuit

Sep 18, 2024 · Here, a simple voltage driven inverter circuit using power transistors as switching devices is build, which converts 12V DC signal to single phase 220V AC. The basic idea

12V DC to 220V AC Inverter Circuit & PCB |12V to 220V Inverter

Feb 12, 2024 · Here, a simple voltage driven inverter circuit using power transistors as switching devices is build, which converts 12V DC signal to single phase 220V AC. An inverter cannot

12v Inverter, 12v DC to 110v/220v AC Power Inverter | inverter

12V 300-watt power inverter for sale. The modified sine wave inverter delivers 600-watt peak power and converts 12V DC from battery or car lighter to AC 110V or 220V household power.

how to make a transformer, inverter 12v to 220v,

May 19, 2023 · Conclusion: Building a transformer-based inverter to convert 12V DC to a 220V AC power supply is a practical solution when you need to power

220v Ac To 12v Dc Converter Circuit

Dec 25, 2019 · The 220V AC to 12V DC Converter Circuit is a must-have for anyone looking for an easy and efficient way to convert AC voltages into DC voltages. Its low cost, versatility, and

On Grid Inverter, Grid Tie Inverter | inverter

1000W grid tie inverter price is reasonable, smart and compact, pure sine wave waveform output, APL functions, converts 12V/ 24V DC to 110V AC 50Hz/ 60Hz automatically, 48V DC to 220V

12V DC to 220V AC Inverter Circuit & PCB

Feb 2, 2025 · Inverter Circuit are very much helpful to produce high voltage using low voltage DC supply or Battery. DC-DC Converter circuit can also be used but it has certain voltage

6 FAQs about [220v AC to 12v DC connected to inverter]

Can an inverter convert 12V DC to 220V AC?

Building an inverter circuit that can convert 12V DC power to 220V AC power is a great way to have a portable power source for your electronics when mains power is not available.

What is a DC to AC inverter circuit?

A DC to AC inverter circuit transforms 12V DC input into 220V AC output, enabling you to power standard household devices from battery sources. This comprehensive guide will walk you through the theory, components, design considerations, and step-by-step construction of a reliable 12V to 220V inverter circuit.

What is a 220V to 12V DC power supply?

The 220v to 12v dc power supply is build to convert AC input to 12 volt DC output. The ac to dc converter project is useful for fixed DC applications like DC motors, pumps, Chargers and many other applications. Here we are going to discuss the what is a dc power supply and circuit for power supply for 12 volt output.

How do you connect a DC inverter to a power supply?

Explanation of the circuit diagram: DC Input: Connect the positive terminal of the +12V DC power supply to the input side of the inverter circuit. Fuse: Place a fuse in series with the input to protect the circuit from excessive current. Power Switch: Add a power switch to control the supply of power to the inverter.

How a 220V AC power source is converted into a DC power source?

All you need to know is that the 220V AC power source is converted into a DC power source with a stable output voltage. The actual conversion process is quite simple – first, the AC voltage is adjusted using a rectifier circuit and then regulated using a voltage regulator circuit.

How to convert 12V to 220V?

F = 1/ (1.38*R2*C1) The inverting signals from the oscillator are amplified by the Power MOSFETS T1 and T4. These amplified signals are given to the step-up transformer with its center tap connected to 12V DC. The turns ratio of the transformer must be 1:19 in order to convert 12V to 220V.

Update Information

- DC 110V to AC 220V inverter

- DC 24V to AC 220V inverter price

- AC inverter 12v to 220v 5KW

- 2120w photovoltaic panel connected to 12v inverter

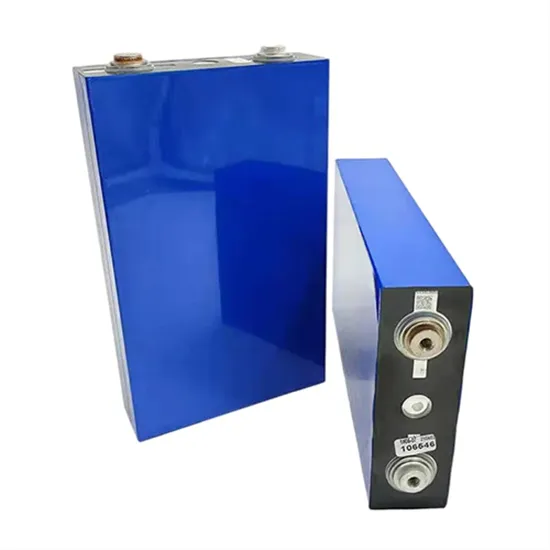

- LiFePO4 12V to 220V inverter

- Strong 12v to 220v inverter

- DC AC inverter bridge

- Looking for 36v DC to 220v inverter

- DC to AC inverter charging adapter

- Differences between AC inverter and DC inverter

- AC Inverter 220v

- DC motor generator connected to inverter

- Pure sine 12V to 220V inverter

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.