Experiment: Single-Phase Full-Bridge sinewave Inverter

Nov 7, 2023 · To overcome the disadvantages of the square-wave PWM, another modulation technique is used for controlling the full-bridge inverter. This method, which called the

Converting DC to AC: Basic Principles of Inverters

May 28, 2024 · Most modern inverters function as solid-state devices that require no moving parts to turn DC into AC power. This allows them to create a higher

10 Tips for Using a Power Inverter Correctly

Jan 24, 2020 · Power inverter that converts DC power to AC power provides a great convenience people''s lives, especially in home appliances, such as air conditioner, refrigerator, TV, VCR,

How to Connect Two Inverters in Parallel: A

Nov 9, 2024 · Connecting two inverters in parallel can significantly increase your power output, making it a popular choice for solar energy systems and backup

A Novel Filter Design for Output LC Filters of PWM

First-order passive L-type filters are normally used on the AC side of PWM inverters when the output AC current is the main control target. The main purpose the of L-type filter is to

(PDF) PV Inverters and Modulation Strategies: A

Mar 1, 2020 · This work presents a non‐isolated single‐phase voltage‐source inverter (VSI) topology using an autotransformer to provide an alternating

AC Motor Inverters: How They Work, Principles, And

May 19, 2025 · AC motor inverters utilize pulse width modulation (PWM) to create a variable voltage and frequency. In PWM, the inverter switches the power on and off rapidly, simulating

Complete Guide to Building a DC to AC Inverter Circuit: 12V

6 days ago · A DC to AC inverter circuit transforms 12V DC input into 220V AC output, enabling you to power standard household devices from battery sources. This comprehensive guide will

Commonly Used Types of Modulation Schemes in Inverters

The most popular modulation technique used in inverters is pulse width modulation (PWM) and the inverters that use this technique are called PWM inverters. PWM inverters eliminate lower

Inverter Basics: Classification and Applications

Jan 3, 2021 · What is an Inverter? In electrical applications, we often come across where one form of electrical energy needs to be converted into another form.

6 FAQs about [How to achieve AC output of inverter]

How do inverters convert DC to AC?

Conversion process: Inverters initially take DC power from sources like batteries or solar panels. They use power electronic devices called transistors to switch the DC voltage rapidly. This switching creates a pulsed output that imitates AC waveform.

Do I need an inverter?

Unless you have a basic system that offers a low-voltage DC power source, the inclusion of an inverter becomes essential. An inverter takes input from a DC (direct current) power supply and generates an AC (alternating current) output, typically at a voltage comparable to that of your standard mains supply.

How does an inverter control a motor?

An inverter uses this feature to freely control the speed and torque of a motor. This type of control, in which the frequency and voltage are freely set, is called pulse width modulation, or PWM. The inverter first converts the input AC power to DC power and again creates AC power from the converted DC power using PWM control.

Do I need a DC to AC inverter?

If you’re using a device powered by a DC source (like a battery) and want to plug it into a wall outlet, you’ll need a DC-to-AC inverter. Air Travel: Aircraft often generate DC power, but the onboard electronics, lighting, and other systems typically run on AC power. Inverters are used to make this conversion.

Are inverters generators?

Inverters are devices that transform direct current (DC) to alternating current (AC). They take power from the DC source and convert it to electrical power; they do not create any additional power and are therefore not generators. The input and output voltage and frequency are specific to each individual inverter and their designed task.

How does a DC inverter work?

The DC source provides the initial electrical power that the inverter converts into AC power. This source can come from batteries or a direct current supply. The efficiency of the inverter depends on the stability and capacity of this source. The inverter circuit is responsible for converting the direct current into alternating current.

Update Information

- How much AC power does the inverter output

- 12V inverter AC output

- Inverter rated AC output power

- How many inverter output voltages are there

- How many volts does the inverter output voltage

- How many communication base station inverter companies are there in Tajikistan

- Inverter AC coupling mode

- How many electrical appliances can a 2kw inverter replace

- How many buildings are there in Tokyo Communication Base Station Inverter

- How big an inverter should I use for a 12V 54AH

- How big an inverter should I use for 33kw

- How difficult is it to design a photovoltaic inverter PCB

- How high should the inverter of a communication base station be installed when connected to the grid

Solar Storage Container Market Growth

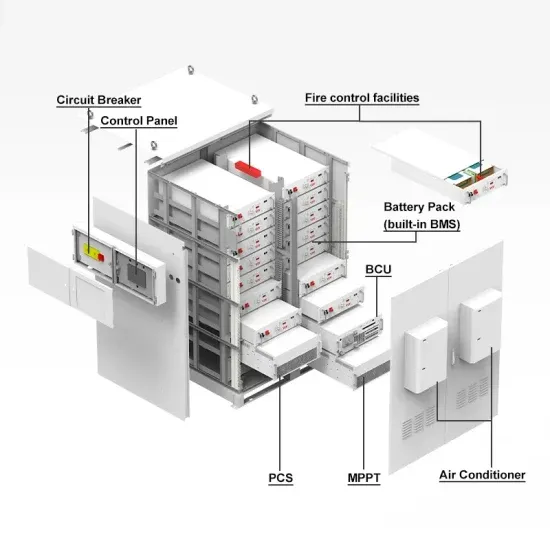

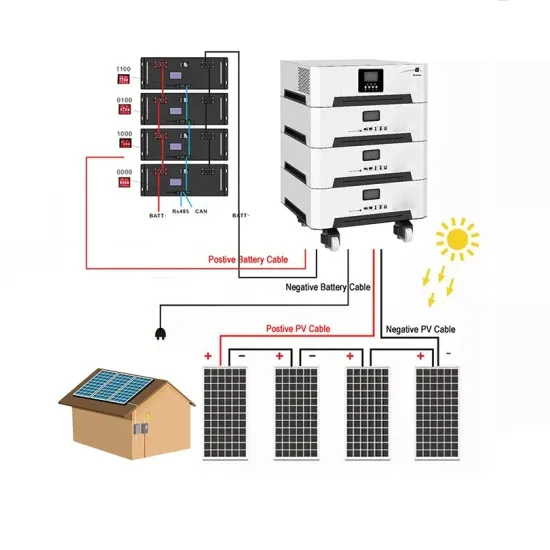

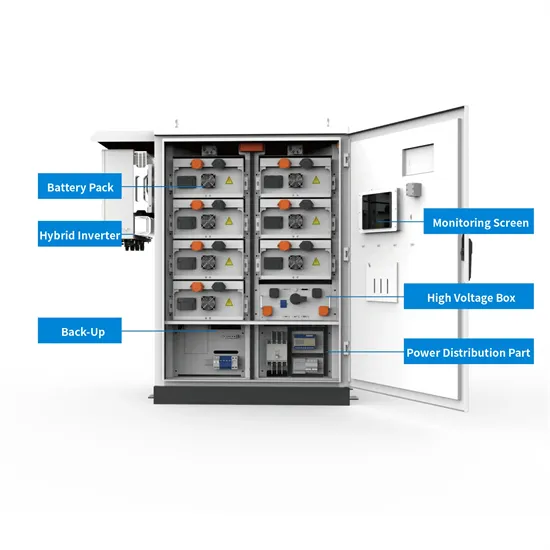

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.