What Is A Pure Sine Wave Inverter? | Definition,

Jan 27, 2025 · A Pure Sine Wave Inverter is a critical component in the world of power conversion, known for delivering clean and stable electrical energy.

What is Inverter Clipping and How to Avoid It?

Feb 17, 2025 · Clipping is a current-limiting protection mechanism that prevents the inverter and battery from being overloaded. Batteries can discharge more power than the inverter can

What Is Inverter Clipping in Solar Power Systems?

Jul 16, 2025 · Learn what inverter clipping means in solar power systems, why it occurs, and how oversizing your solar array affects energy harvest and efficiency.

What Are The Advantages And Disadvantages Of A Pure Sine Wave Inverter

Jan 27, 2025 · Discover the advantages and disadvantages of a pure sine wave inverter, including smooth power delivery, efficiency, compatibility with sensitive electronics, and more. Learn

Inverter clipping: How to maximize solar project value

Sep 11, 2024 · Inverter clipping refers to the phenomenon where an inverter discards excess power when the power produced by solar panels exceeds the inverter''s processing capability.

800VA Pure Sine Wave Inverter''s Reference Design (Rev

Jan 10, 2025 · The pure Sine Wave inverter has various applications because of its key advantages such as operation with very low harmonic distortion and clean power like utility

⚡ What is a Pure Sine Wave Inverter and Why Does it Matter?

Jun 10, 2025 · Electricity that comes from the power grid is in the form of a sine wave—a smooth, repeating wave that maintains a consistent frequency (usually 50 or 60 Hz). A pure sine wave

Sizing an Inverter for a Solar Power System

Mar 31, 2023 · Therefore, it is important to carefully match the inverter''s input voltage to the battery bank voltage to ensure reliable and efficient operation of

Pure Sine Wave Inverter: Clean Power Guide 2025

Apr 21, 2025 · A pure sine wave inverter is a critical component in delivering stable and high-quality electrical power to sensitive electronic equipment. In this comprehensive guide, we''ll

AN-CM-374 Sine Wave Based Inverter

Nov 27, 2024 · SLG47004 This app note describes how the AnalogPAK SLG47004 can be used as the core of a sine wave-based inverter useful for automotive and renewable energies

SN74AUP1G14: Sine wave (or clipped) to square wave for

Apr 5, 2023 · There are a few different ways to approach your solution, but my recommendation would be to use an unbuffered inverter to convert your sine wave to a square wave, likely with

Inverter Saturation or "Clipping" – PV Performance Modeling

Inverter saturation, commonly referred to as "clipping", occurs when the DC power from the PV array exceeds the maximum input level for the inverter. In response to this condition, the

Quantifying the impact of inverter clipping on photovoltaic

May 1, 2024 · Clipping occurs when the inverter''s AC size is smaller than the overall modules'' DC capacity and leads to the conversion of only part of the PV-generated DC energy into AC. This

What REALLY requires a pure sine inverter?

Apr 29, 2020 · A pure sine wave inverter uses more power at idle and much more post processing of the digital pulses in order to deliver the smooth and clean AC wave form. Circuit designers

Worried about clipping? Don''t be

Feb 9, 2014 · In practice, clipping results in the top of the daily AC output sine wave being flattened off as shown in the image above. PV system designers can avoid clipping by sizing

Redefining Inverter Clipping and Solar Efficiency

Jun 18, 2024 · Meaning, that the inverter will only convert DC to AC power until its saturation level, and this saturation of the inverter is termed as "clipping",

What Causes Clipping of An Amplifier Output Signal?

Dec 29, 2024 · Content Menu Understanding Clipping >> Types of Clipping Causes of Clipping >> 1. Overdriven Amplifier >> 2. Inadequate Power Supply >> 3. High Input Signal Levels >> 4.

800VA Pure Sine Wave Inverter''s Reference Design

Apr 1, 2023 · The pure Sine Wave inverter has various applications because of its key advantages such as operation with very low harmonic distortion and clean power like utility-supplied

Distortion, Clipping, and Square Waves

The "overheating piston" action that people claim occurs with a square wave simply does not happen in reality, at least not to any degree more than other big signal peaks; and again in

How to measure a clipped and non-clipped sinewave

Jun 14, 2009 · Hi all, In my inverter project, I am generating a sine wave 230V with PWM using a full bridge of MOSFETs. The feedback is to be measured with an ADC built in the MCU. I need

What is Solar Inverter Clipping?

Apr 27, 2020 · Solar inverter clipping occurs when a solar inverter reaches its peak output. Even if additional power is available from the solar panels, the inverter will disallow any further input

Understanding Clipped Sine Wave Oscillators in the

Sep 27, 2023 · Clipped sine wave oscillators play a crucial role in the field of electronics components, specifically within the frequency components sector. This article aims to explore

6 FAQs about [Sine wave clipping occurs in the inverter]

What is inverter clipping?

Inverter clipping, or “inverter saturation,” occurs when DC power from a PV array exceeds an inverter’s maximum input rating. The inverter may adjust the DC voltage to reduce input power, increasing voltage and reducing DC current. Alternatively, the inverter may restrict or throttle the inverter’s AC output.

Why do inverters clip?

The inverter may adjust the DC voltage to reduce input power, increasing voltage and reducing DC current. Alternatively, the inverter may restrict or throttle the inverter’s AC output. Inverter clipping is typically seen in PV systems that have high — for example, greater than 1.4:1 — DC/AC ratios. Why does it matter?

What is a clipped sinewave CMOS inverter?

The above circuit is a clipped sinewave CMOS inverter that converts a clipped sinewave waveform to a CMOS waveform. The CMOS inverter selection must be rated for the frequency of operation, and this circuit can work up to 100 MHz with proper selection.

What is a sine wave inverter?

Honda developed the Microprocessor-controlled Sine Wave Inverter in 1998, which allows the supply of electricity with a waveform clean enough to power ordinary electric appliances, according to the load. Honda continues to pursue the ideal safe-and-secure generator, addressing every issue that arises while meeting changing requirements with the times.

Does inverter clipping affect solar system performance?

Contractors — more specifically, system designers — across all segments of the solar industry will at some point evaluate the impact of inverter clipping on their system’s generation capacity and performance.

What is inverter saturation?

Inverter saturation, commonly referred to as “clipping”, occurs when the DC power from the PV array exceeds the maximum input level for the inverter. In response to this condition, the inverter typically adjusts DC voltage to reduce the DC power. This is done by increasing voltage above the MPP voltage, thus reducing DC current.

Update Information

- Kuwait sine wave inverter device

- Pure sine wave inverter 24v low power

- France Lyon pure sine wave inverter supply

- Price quote for pure sine wave inverter in Zurich Switzerland

- Sine wave or inverter

- Sine wave inverter characteristics

- Producing inverter sine wave

- Branded industrial frequency pure sine wave inverter

- Russia St Petersburg pure sine wave inverter manufacturer

- Inverter sine wave selection

- Using IGBT to produce sine wave inverter

- Tskhinvali sine wave inverter company

- Cabinet type sine wave inverter

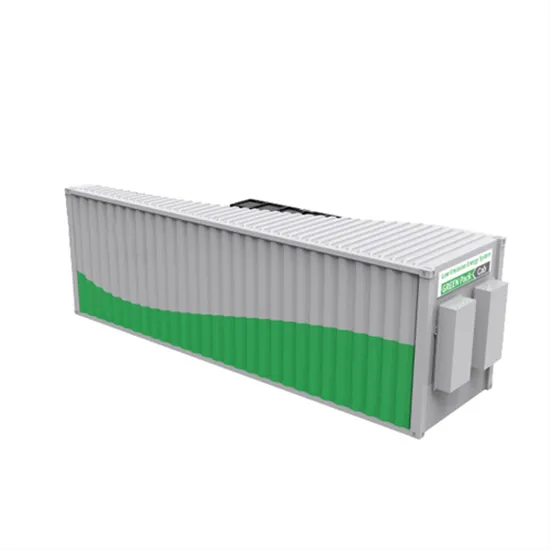

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

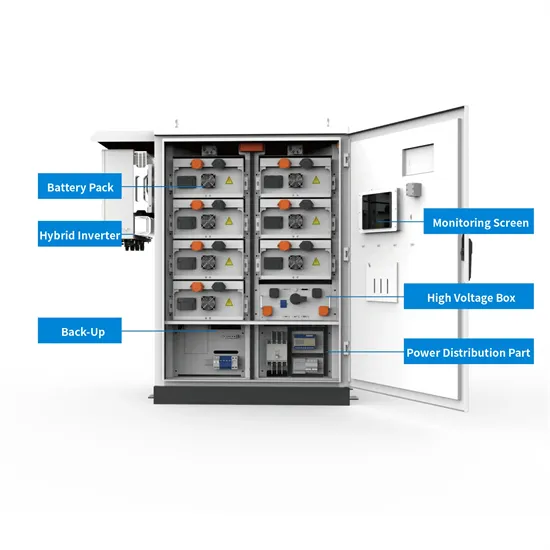

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.