Malaysian developer Gentari poised to start work on first

Mar 11, 2025 · Both BESS and solar farm will be DC-coupled and behind the inverter, allowing the flow of electricity to be smoothed and stored – and helping to alleviate any curtailment. The

(PDF) Construction and Evaluation of a Power

Jul 1, 2015 · [5] has mentioned [1] described inverter has a special type of power inverters that convert direct current (DC) electricity into alternating current

The Essential Guide: 7 Wiring Diagrams for Power Inverter

Jun 4, 2025 · A power inverter schematic diagram is a visual representation of the electrical components and their connections within a power inverter. It provides a comprehensive

Design, Construction and Implementation of 1KVA Inverter

Nov 28, 2024 · The construction of this project 1kVA, 220volts inverter at a 50Hz frequency was a gradual process from gathering of materials to testing of

Design and Construction of 1KW (1000VA) Power Inverter

The purpose of this project is to design and construct a 1000Watts (1KW) 220 Volts Inverter at a frequency of 50Hz. This device is constructed with locally sourced components and materials

design and construction of a dc to ac inverter system

design and construction of a dc to ac inverter system This project covers the design and construction of 2.5KVA inverter with the following stages – Power Supply unit, Inverting unit,

design and construction of a dc to ac inverter system

This project covers the design and construction of 2.5KVA inverter with the following stages – Power Supply unit, Inverting unit, Power transformer unit, triggering unit. The scope of this

Wellington Solar Farm » Projects » GCo Solar

Nov 29, 2023 · GCo Solar P/L were engaged by Sterling & Wilson to deliver the Electrical services component of a 200MWpDC Solar Farm in Wellington,

DC-to-AC Converters (Inverters): Design, Working &

Dec 28, 2019 · This report focuses on DC to AC power inverters, which aim to efficiently transform a DC power source to a high voltage AC source, similar to

Design And Construction Of A Solar Inverter

This work is on design and construction of a 12VDC to 220VAC solar power supply. Solar inverter converts the variable direct current (DC) output of a photovoltaic (PV) solar panel into a utilizy

Wellington Solar Farm » Projects » GCo Solar

Nov 29, 2023 · GCo was responsible for the Electrical MV, DC,PV, CCTV inground and above ground construction activities. The project includes 489,600 Bi Facial Panels and a single axis

6 FAQs about [Wellington DC inverter construction]

What is a DC to AC power inverter?

This report focuses on DC to AC power inverters, which aim to efficiently transform a DC power source to a high voltage AC source, similar to power that would be available at an electrical wall outlet.

How to invert low voltage DC power?

The method, in which the low voltage DC power is inverted, is completed in two steps. The first being the conversion of the low voltage DC power to a high voltage DC source, and the second step being the conversion of the high DC source to an AC waveform using pulse width modulation.

Do I need a DC to AC inverter?

If you’re using a device powered by a DC source (like a battery) and want to plug it into a wall outlet, you’ll need a DC-to-AC inverter. Air Travel: Aircraft often generate DC power, but the onboard electronics, lighting, and other systems typically run on AC power. Inverters are used to make this conversion.

How do inverters convert DC voltage to AC voltage?

Most inverters rely on resistors, capacitors, transistors, and other circuit devices for converting DC Voltage to AC Voltage. In alternating current, the current changes direction and flows forward and backward. The current whose direction changes periodically is called an alternating current (AC). It has non-zero frequency.

What is a DC to AC converter?

The electrical circuits that transform Direct current (DC) input into Alternating current (AC) output are known as DC-to-AC Converters or Inverters. They are used in power electronic applications where the power input pure 12V, 24V, 48V DC voltage that requires power conversion for an AC output with a certain frequency.

What is inverter design & construction?

INVERTER DESIGN AND CONSTRUCTION The inverter is a two operation modes device, the inverting and the charging modes. The inverting mode comprises of the oscillator, the driver, the output (MOSFET) section, the PWM section, low battery / overload protection circuit, and the transformer.

Update Information

- Does the inverter have a DC output

- 2Kw inverter can drive K watt DC equipment

- Communication base station inverter grid-connected construction project management

- Mechanical inverter DC 12V

- High Voltage DC Step-Down Inverter

- Inverter DC cabinet structure price

- DC AC boost inverter price

- Bulgaria 48V DC Inverter

- 5G communication base station inverter under construction in Luanda

- Inverter DC power supply

- 220v AC to 12v DC connected to inverter

- DC to three-phase AC inverter

- 100W DC Inverter

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

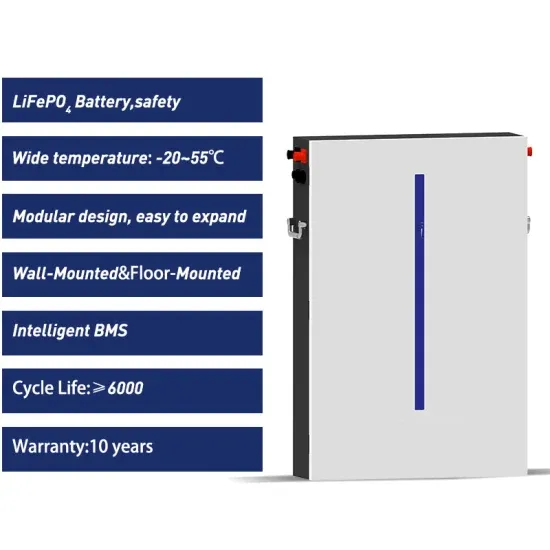

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.