The Crucial Role of a Battery Management System (BMS) in

Sep 18, 2024 · A Battery Management System (BMS) is a pivotal component in the effective operation and longevity of rechargeable batteries, particularly within lithium-ion systems like

What Is a Battery Management System (BMS)?

Aug 7, 2025 · A BMS is not a single function but rather an integrated suite of operations designed to oversee and control the health and safety of the battery pack. The core functions can be

What Is a Battery Management System (BMS)?

Aug 7, 2025 · A Battery Management System (BMS) is an essential component in modern battery-powered applications, responsible for monitoring, protecting, and optimizing the

What Is BMS in an Electric Vehicle (EV)?

Oct 20, 2023 · The system is incorporated in an EV powered with a large-capacity lithium ion battery, and plays an important role in extending the service life of the battery and ensuring

What Is the Role of a Battery Management System (BMS) in

Nov 6, 2024 · A Battery Management System (BMS) is essential for the safe and efficient operation of lithium-ion battery packs, particularly in applications such as electric vehicles and

What is the function of BMS in battery?

Nov 30, 2023 · We''re diving into a whole new world – the Battery Management System! If you''ve ever wondered how batteries perform at their best, or why they sometimes fail miserably, then

Why is a Battery Management System needed in

May 14, 2020 · This article is a part of EVreporter Learning series. We explore the following basic questions regarding the Battery Management System (BMS) –

What Is A BMS Battery Management System?

A Battery Management System (BMS) is an electronic control unit that monitors and manages rechargeable battery packs. It ensures safety by preventing overcharging, over-discharging,

Battery Management System (BMS) Detailed Explanation:

May 7, 2025 · BMS is like a 24-hour on duty ''battery doctor'', mainly responsible for completing six major tasks: Collect voltage, current, temperature and other data to ensure transparency of

Battery Management System (BMS) in Battery Energy

Sep 15, 2024 · Learn about the role of Battery Management Systems (BMS) in Battery Energy Storage Systems (BESS). Explore its key functions, architecture, and how it enhances safety,

What is a Battery Management System (BMS)? –

1 day ago · Battery management system (BMS) is technology dedicated to the oversight of a battery pack, which is an assembly of battery cells, electrically

What is a Battery Management System (BMS)? Key Functions

Jun 26, 2025 · A Battery Management System (BMS) is an electronic system that manages a rechargeable battery, such as one found in an electric vehicle or a large solar power station.

What is a Battery Management System? Complete Guide to BMS

Aug 3, 2025 · A Battery Management System (BMS) is an electronic control unit that monitors and manages rechargeable battery packs to ensure safe operation, optimal performance, and

What is Battery Management System (BMS)?

Dec 3, 2024 · A battery management system, or BMS for short, is an electrical system that regulates and maintains a battery''s performance. By regulating several factors, including

What Is a BMS and How Do Battery Management Systems

Dec 30, 2024 · What is a BMS? A battery management system (BMS) is an electronic system that manages the functioning of rechargeable batteries, which are the primary power source in

What is a BMS for Lithium Batteries?

Dec 8, 2023 · A Battery Management System (BMS) for lithium batteries is an electronic system that manages and monitors the performance, safety, and longevity of battery packs. By

6 FAQs about [What are the functions of battery BMS]

What is battery management system (BMS)?

Battery Management System (BMS) is the “intelligent manager” of modern battery packs, widely used in fields such as electric vehicles, energy storage stations, and consumer electronics.

How do battery management systems work?

Battery management system (BMS) is technology dedicated to the oversight of a battery pack, which is an assembly of battery cells, electrically organized in a row x column matrix configuration to enable delivery of targeted range of voltage and current for a duration of time against expected load scenarios.

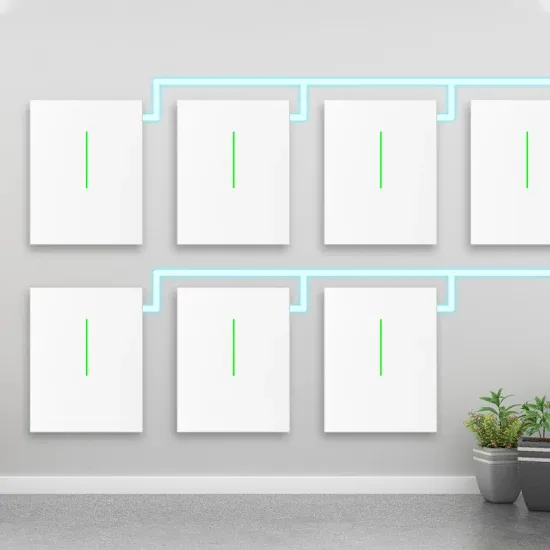

What are the different BMS architectures for a battery system?

Different battery systems call for different BMS architectures: Centralized: Single controller handles all cell data Distributed: Module-level sensors report to a central unit Modular: Smart modules manage subsets of the battery independently Sensors: Voltage, current, temperature Microcontroller (MCU): BMS “brain” for logic and data processing

Why are battery management systems important?

Safety represents the primary driver behind BMS requirements in most applications, as modern lithium-ion batteries store tremendous amounts of energy in compact packages. Beyond safety considerations, battery management systems provide significant performance benefits that justify their implementation.

Why is BMS technology important?

This sophisticated technology acts as the brain of modern battery systems, protecting against dangerous conditions like overcharging, overheating, and cell imbalances. From electric vehicles to renewable energy storage systems, BMS technology has become essential for safely harnessing the power of advanced battery chemistries.

How does a BMS protect a battery pack?

Monitoring battery pack current and cell or module voltages is the road to electrical protection. The electrical SOA of any battery cell is bound by current and voltage. Figure 1 illustrates a typical lithium-ion cell SOA, and a well-designed BMS will protect the pack by preventing operation outside the manufacturer’s cell ratings.

Update Information

- What does BMS mean in battery

- What is the approximate cost of a lead-acid battery BMS

- Specific functions of power battery BMS

- Main functions of BMS battery management system

- What are the functions of photovoltaic energy storage battery cabinets

- BMS battery optimization management

- Conakry lithium battery bms manufacturer

- What battery is best for a 12v2 kilowatt inverter

- What are the Freetown container energy storage battery manufacturers

- What is the voltage of a general energy storage battery

- What is the Ngerulmud EK energy storage battery

- What kind of batteries are usually replaced in battery cabinets

- What are the Nordic outdoor communication battery cabinet suppliers

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.