10 kVA – 120 kVA Threephase Online UPS Uninterruptible Power Supply

Aug 13, 2025 · 10 kVA – 120 kVA Three-Phase Online UPS Three-phase Online UPS with 10 kVA – 120 kVA capacity are professional power solutions designed for the critical energy needs of

UPS sizing for Control Systems: Key Considerations for

When it comes to control systems, choosing the right Uninterruptible Power Supply (UPS) is crucial for ensuring uninterrupted operation and safeguarding sensitive equipment. The size of

What Is UPS in PLC?

Jan 13, 2024 · Programmable Logic Controllers (PLCs) play a crucial role in industrial automation, managing and controlling manufacturing processes with precision. To ensure the uninterrupted

Manual Uninterruptible Power Supply (Capacitive)

Dec 9, 2024 · The CU8110-0120 is a capacitive uninterruptible power supply (UPS) based on double-layer capacitors (EDLC) with a maximum energy of 0.9 Wh and a maximum power

How to Size an Industrial UPS System for PLC Backup

Jun 26, 2025 · To size an industrial UPS system for PLC (Programmable Logic Controller) backup applications, follow these concrete steps: 1. Determine Load Requirements. a. List All Devices.

Siemens 6ep1935-6MD11 PLC Uninterruptible Power Supply UPS

Jun 13, 2025 · The Siemens 6EP1935-6MD11 PLC Uninterruptible Power Supply (UPS) Systems are designed to provide reliable power protection for industrial automation and control systems.

Bulletin 1609 Next Generation Industrial UPS

Sep 26, 2017 · Features and Benefits The 1609 family of Industrial Uninterruptible Power Supplies is designed for industrial applications – with features required for remote control and operation

不斷電系統 (UPS) 市場規模:按類型、容量、應用和

Mar 20, 2024 · 不斷電系統 (UPS) 市場規模:按類型、容量、應用和最終用戶分類 - 區域展望、競爭策略和細分市場預測(截至 2033 年) Uninterruptible Power Supply (UPS) Market Size-

SANTAK PLC controlling sYstem uninterruptible power supply

High reliability architecture: Output transformer vacuum impregnation treatment, redundant power supply and fan, passed 100% factory aging test. Isolation transformer standard configuration:

How to calculate the required ups load capacity?

Oct 19, 2023 · That is to say, one only runs the uninterruptible power supply system around 80% of the capacity to support the load calculated. For example, if the total required capacity/load is

6 FAQs about [PLC uninterruptible power supply capacity]

How do I calculate the capacity of an uninterruptible power supply (UPS)?

Calculating the capacity of an Uninterruptible Power Supply (UPS) involves multiple considerations, including load power, backup time, efficiency, and load characteristics. This guide provides a detailed breakdown to help you select the right UPS for your needs. Start by calculating the total power requirements of all connected devices.

What is an uninterruptible power supply (UPS)?

Uninterruptible power supplies are far more present in industrial automation systems than many realize. Any control panel with a well-designed power protection framework will include an uninterruptible power supply (UPS) as its key component.

Which control panel has an uninterruptible power supply (UPS)?

Any control panel with a well-designed power protection framework will include an uninterruptible power supply (UPS) as its key component. Server rooms, industrial PCs, mobile applications (stacker cranes, AMR's), and others may also include a UPS.

What is a PLC power supply?

The power supply in a PLC system converts high-voltage alternating current (AC), commonly 120V or 240V AC, into a stable, lower-voltage direct current (DC), typically 24V DC, that the PLC and its components require to operate.

Should you use uninterruptible power supplies (UPS) as a countermeasure?

In particular, in places such as factories and data centers where an interruption in the power supply can have a significant impact, it is necessary to use Uninterruptible Power Supplies (UPS) as a countermeasure. However, risk management in the unlikely event that the UPS itself fails can be a blind spot.

Can a PLC power supply power a field device?

The PLC power supply unit powers only the CPU and communication modules. Sensors, actuators, and other field devices require separate power sources. Field devices may use 24V DC, 48V DC, or even 120V AC, depending on the application. To ensure proper operation, always verify the power supply specifications for both PLC and field devices.

Update Information

- Maldives large capacity uninterruptible power supply

- Small capacity UPS uninterruptible power supply

- ASEAN EK Uninterruptible Power Supply Equipment

- Price of UPS uninterruptible power supply in Rwanda

- Yemen Uninterruptible Power Supply Purchasing Company

- Uninterruptible power supply properties and co-location of communication base stations

- Asuncion backup uninterruptible power supply

- Uninterruptible power supply without built-in battery

- Brazil processing UPS uninterruptible power supply wholesaler

- Lobamba Uninterruptible Power Supply

- Redundant Power Supply and Uninterruptible Power Supply

- What is the maximum power of the UPS uninterruptible power supply in the computer room

- Imported UPS uninterruptible power supply

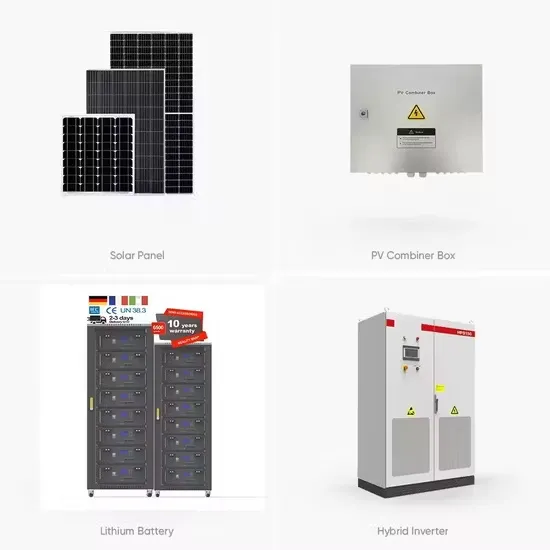

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.