Designing a BESS Container: A Comprehensive Guide to Battery Energy

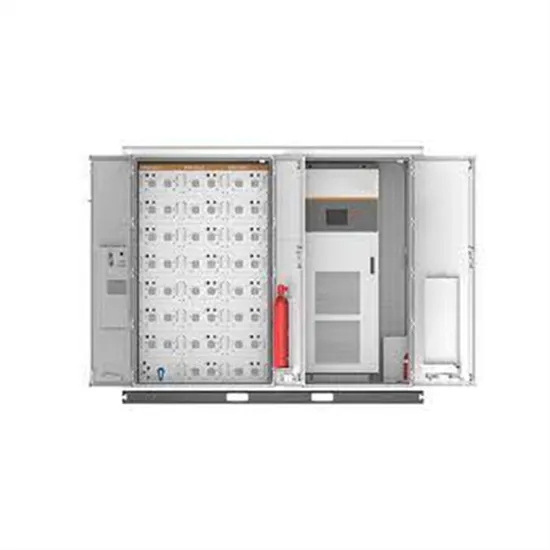

Apr 10, 2023 · The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system.

Energy storage systems in South Korea

Mar 6, 2025 · Domestic infrastructural support for large-scale utilization, improved safety due diligence, and quick adoption of new technologies are some of the concerns likely to heavily

Busan South Korea s energy storage battery industry

Busan, South Korea is set to become a hub for energy storage battery production with a significant investment from DN Automotive. The company plans to build a state-of-the-art

South Korea • Renewable energy • Hydrogen, Marine,

Apr 9, 2025 · The major South Korean wind turbine manufacturers are Doosan, Hanjin, Hyosung Wind Energy, Hyundai Heavy Industries, STX Corporation Windpower and Unison. Most of

Korea Energy Storage Power: Innovations, Challenges, and

Jan 13, 2022 · With Korea aiming to achieve 20% renewable energy by 2030, energy storage systems (ESS) have become the nation''s secret sauce for balancing solar spikes and wind

Huawei Busan Battery Energy Storage Project in South

The Gyeongsan Substation - Battery Energy Storage System is a 48,000kW lithium-ion battery energy storage projectlocated in Jillyang-eup,North Gyeongsang,South Korea. The rated

Design of Seoul Energy Storage Container Park: Powering

Dec 23, 2020 · Ever wondered how a mega-city like Seoul keeps its lights on while slashing carbon footprints? Meet the game-changer: the Seoul Energy Storage Container Park. This

Busan South Korea Container Energy Storage Equipment

Summary: As a leading container energy storage equipment manufacturer in Busan, South Korea, we explore how modular energy storage systems are transforming industries like renewable

Strategic Place for Global Logistics | Busan

The Hub of Marine Logistics in Northeast Asia As of 2024, Port of Busan, the world''s second-largest transshipment port and the seventh-largest container port, is the largest port in Korea

Wholesale Energy Storage Manufacturers in South Korea

Jun 7, 2025 · Busan, South Korea''s second-largest city, is strategically positioned as a port city, making it an ideal hub for energy storage manufacturers. Renowned for its advanced logistics

South Korea launches its largest energy storage bid to

Aug 18, 2025 · South Korea''s trade ministry announced Thursday it will invite bids from private companies to build and operate a large energy storage system (ESS) totaling 540 megawatts

Busan South Korea energy storage battery container

Municipal authorities in the South Korean port city of Busan have designed a flame-retardant and insulated container to ensure that lithium-ion batteries can be transported safely, considering

South korean energy storage station incident

"The South Korean government is already in the process of reviewing it regulations, but we strongly recommend that South Korean energy storage systems project developers invest

Supplier of energy storage explosion-proof container in

DP World has announced the first commercial use of its revolutionary BOXBAY high-bay storage system at their terminal in Pusan, South Korea. A contract was signed on 8th March between

South Korea • Renewable energy • Hydrogen, Marine,

Aug 6, 2024 · The major South Korean wind turbine manufacturers are Doosan, Hanjin, Hyosung Wind Energy, Hyundai Heavy Industries, STX Corporation Windpower and Unison. Most of

South korea s energy storage scale

South Korea had 6,848MW of capacity in 2022 and this is expected to rise to 36,454MW by 2030. Listed below are the five largest energy storage projects by capacity in South Korea, according

6 FAQs about [South Korea Busan MW energy storage container]

What is energy storage capacity in Korea?

k (IRENA,2018).06Grid Energy StorageIn KoreaSince 2018,the total capacity of all energy storage systems (ESS) connected to the Korean power sy tem has reached 1.6 GWand 4.8 GWh (NARS,2021). In terms of power capacity,40% of ESS are used for peak load reduction,36% in hybrid systems (i.e.,a combination of

Why is South Korea launching a 540mw battery energy storage tender?

South Korea is ramping up its battery energy storage deployment with a new 540MW tender to stabilize the grid and support renewable energy growth. Learn how this move strengthens both domestic resilience and global market leadership.

What is Gyeongsan substation – battery energy storage system?

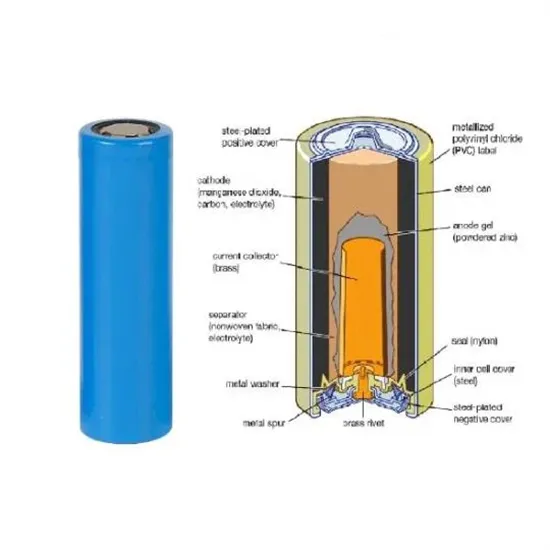

The Gyeongsan Substation – Battery Energy Storage System is a 48,000kW lithium-ion battery energy storage project located in Jillyang-eup, North Gyeongsang, South Korea. The rated storage capacity of the project is 12,000kWh. The electro-chemical battery storage project uses lithium-ion battery storage technology.

What is Ulsan substation energy storage system?

The Ulsan Substation Energy Storage System is a 32,000kW lithium-ion battery energy storage project located in Namgu, Ulsan, South Korea. The rated storage capacity of the project is 8,000kWh. The electro-chemical battery storage project uses lithium-ion battery storage technology. The project was announced in 2016 and will be commissioned in 2017.

What is Uiryeong substation – Bess?

The Uiryeong Substation – BESS is a 24,000kW lithium-ion battery energy storage project located in Daeui-Myoen, Uiryeong-Gun, South Gyeongsang, South Korea. The rated storage capacity of the project is 8,000kWh. The electro-chemical battery storage project uses lithium-ion battery storage technology.

What is Asia's largest battery energy storage system?

Billed as Asia’s largest battery energy storage system for grid stabilization purposes, the system has a power output of 978 MW and a storage capacity of 889 MWh. The ceremony marking the completion of construction was held on Thursday, September 27, at the 154 kV Bubuk Substation in Miryang.

Update Information

- Energy storage power supply companies in Busan South Korea

- South Korea Busan Hydropower Fourth Bureau Energy Storage Project

- Busan South Korea energy storage supercapacitor price

- Busan South Korea energy storage equipment new energy enterprise

- Lithium-ion energy storage battery in Busan South Korea

- What is the price of MW energy storage container in Kuala Lumpur

- Mw energy storage container how much

- Energy storage batteries imported from South Korea

- South Korea s cascade battery energy storage power station

- South Africa Container Energy Storage Station

- South Korea 5g communication base station battery energy storage system construction ESS system

- Container energy storage product base station

- Castrie container energy storage cabinet quotation

Solar Storage Container Market Growth

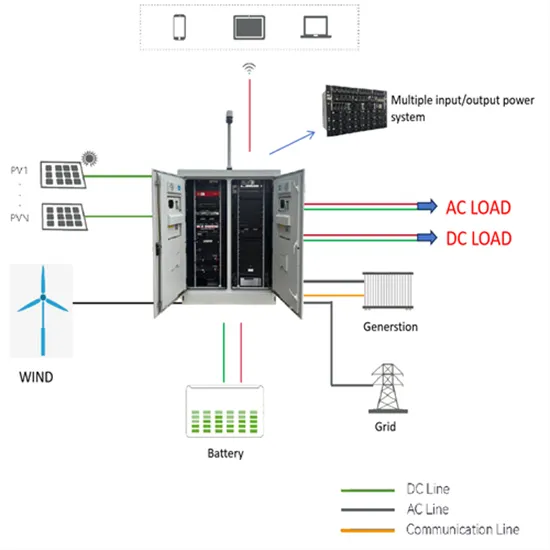

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

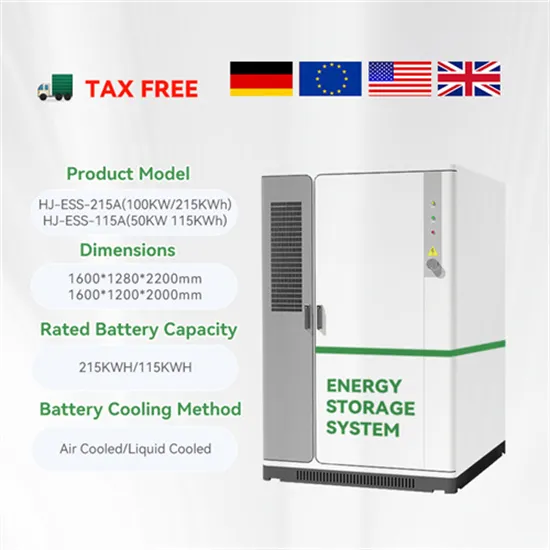

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.