Analysis of Cylindrical Lithium Battery Advantages and

1. Definition of cylindrical lithium battery Cylindrical lithium battery is a kind of lithium ion battery, its shape is cylindrical, so it is called cylindrical lithium battery. The structure of a typical

What is the relationship between voltage and capacity of 18650 li

Sep 26, 2019 · The lithium-ion battery voltage is 3.7V, the charge cut-off voltage is 4.2v, the lithium iron phosphate battery has a nominal voltage of 3.2V, the charge cut-off voltage is 3.6v,

A lumped-parameter electro-thermal model for cylindrical batteries

Jul 1, 2014 · Combining several existing lumped-parameter models, this paper presents an electro-thermal model for cylindrical batteries. The model consists of two

Lithium Battery Voltage Guide: Types, Charging

Jan 27, 2024 · Lithium battery voltage determines not only energy capacity but also affects charging requirements and device compatibility. This comprehensive guide explains key

Lithium battery cylindrical model, cylindrical

Aug 1, 2025 · At present, the cylinders are mainly steel-shell cylindrical lithium iron phosphate batteries, which are characterized by high capacity, high

Diffusion Induced Stresses in Cylindrical Lithium-Ion Batteries

Oct 17, 2012 · Cylindrical electrode, which is one of the mostly employed structures in real Li-ion batteries, has a helical structure which is coiled with multiple layers including copper current

What are cylindrical lithium batteries and their advantages?

Dec 11, 2023 · Compared with soft pack lithium batteries and square lithium batteries, cylindrical lithium batteries have the longest development time, higher standardization level, more mature

Cylindrical vs. Prismatic vs. Li-Po Battery: Key

Feb 29, 2024 · Curious about battery types? Learn how cylindrical, prismatic, and lithium polymer batteries stack up against each other. Make the best choice!

Everything You Need to Know About Cylindrical Batteries

Apr 24, 2025 · Cylindrical batteries can be categorized based on their filler materials into several types: lithium iron phosphate batteries, lithium cobalt oxide batteries, lithium manganese oxide

Experimental investigation on mechanical-electrochemical

Apr 15, 2024 · Mechanical-electrochemical coupling experiments were conducted to investigate the impact of mechanical abuse of cylindrical compression on battery capacity and

Cell geometry influences on the vibration performance of lithium

Feb 15, 2025 · Lithium-ion batteries are rechargeable energy storage systems in which lithium ions travel between negative and positive electrodes during charging and discharging [1]. In

[LiFePO4 Battery Types] Cylindrical vs. Prismatic

Oct 22, 2024 · LiFePO4 batteries, or lithium iron phosphate batteries, are increasingly recognized for their remarkable safety, longevity, and versatility.

Types of Cylindrical Lithium-ion Cell

Apr 13, 2023 · Ⅰ. Introduction of cylindrical lithium-ion cell Cylindrical lithium batteries are divided into lithium cobalt oxide, lithium manganate, and ternary materials. The three data system

Tesla Battery Voltage | Find Each Of The Battery

Aug 12, 2023 · Tending the battery for a Tesla car is very essential as it determine the range of distance it can run without charging. Knowing the right

Investigation of the electrical and thermal characteristics of

Sep 1, 2024 · These investigations mainly pertain to conventional cylindrical or pouch lithium-ion batteries, with limited attention given to the study of semi-solid-state LFP (Lithium Iron

6 FAQs about [What is the voltage of a semi-cylindrical lithium battery ]

What is a cylindrical lithium battery?

The cylindrical battery shell has high voltage resistance and will not cause swelling of square or soft-packaged batteries during use. The cylindrical lithium battery cell size is larger. When the current is discharged, the internal temperature of the winding core is relatively high.

What voltage does a lithium ion battery use?

The standard lithium battery voltage ranges between 3.2V to 4.2V depending on chemistry. Most common lithium-ion batteries operate at 3.7V nominal voltage, while lithium iron phosphate (LiFePO4) batteries use 3.2V per cell.

How many volts is a lithium polymer battery?

Single lithium polymer (Li-Po) cells typically have a nominal voltage of 3.7 volts. When the voltage of this type of cell is charged to 4.2 volts, it is considered fully charged. During the battery discharge process, when the voltage drops to 3.27 volts, the battery is considered fully discharged.

How does a lithium ion battery charge?

During charging, lithium-ion batteries exhibit distinct voltage characteristics that reflect their electrochemical processes. The charging cycle typically follows a constant current-constant voltage (CC-CV) protocol. Initially, the battery voltage rises steadily as current flows into the cell.

What is lithium battery chemistry?

Lithium Battery Chemistry: Different lithium battery chemistries have distinct voltage characteristics. For instance, LiFePO4 batteries typically have a lower nominal voltage (around 3.2 volts per cell) than Li-ion batteries (about 3.6 to 3.7 volts per cell).

What are the different types of lithium batteries?

Different types of lithium batteries have varying maximum charge voltages: Li-ion Batteries: Typically have a max charge voltage between 4.2 to 4.3 volts per cell. LiPo Batteries: Share a similar range with Li-ion batteries, ranging from 4.2 to 4.3 volts per cell.

Update Information

- What is the minimum voltage of the 6-series lithium battery pack in China and Europe

- What is the charging voltage of a 24V lithium battery pack

- What is the maximum watt inverter that can be used with a 12v 60A lithium battery

- What does lithium battery ESS mean

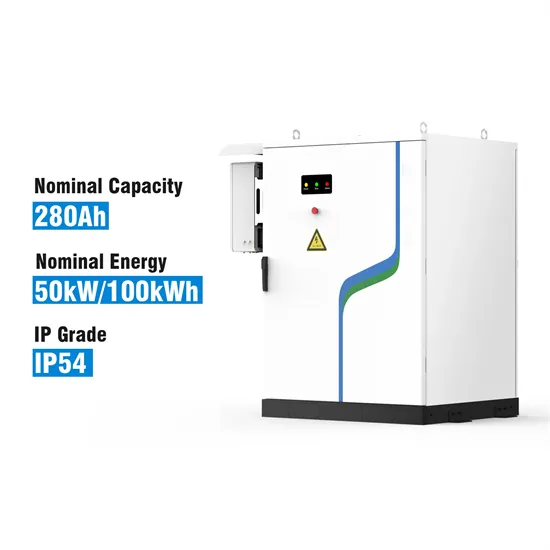

- What size lithium battery is in the battery cabinet

- 24v lithium battery 300a with what size inverter

- Lithium battery pack high voltage

- What is the capacity of a large cylindrical lithium battery

- Minimum voltage of lithium battery pack

- What is the maximum voltage of the inverter battery

- What is the voltage of a general energy storage battery

- Power tool lithium battery voltage and battery quantity

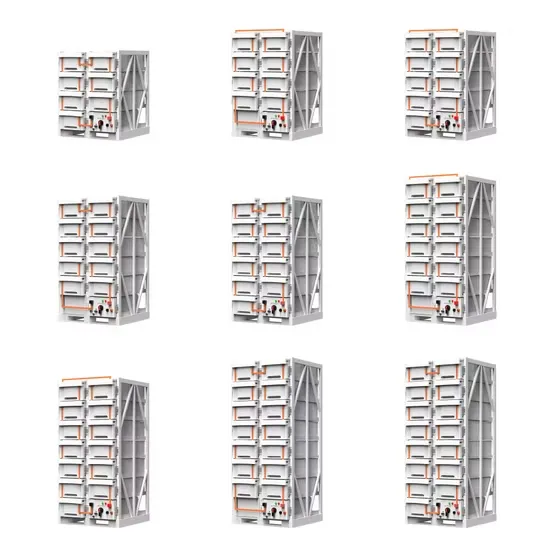

- What are the units of lithium battery container energy storage system

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.