SolarEdge System Design and the NEC

Nov 30, 2022 · Since the maximum number of power optimizers is limited to 50 or less the maximum safety voltage of the system is limited to approximately 50 Vdc (277/480 Vac

Inverter Battery Voltage: How Many Volts Are Needed For

Mar 27, 2025 · An inverter battery typically operates at 12V, 24V, or 48V. These voltages represent the nominal direct current (DC) needed for the inverter''s function. Selecting the

Battery Capacity For Inverter Calculator

Where: Inverter Load Power — Total wattage of connected devices Backup Time — Desired runtime during power outage Inverter Battery Voltage — System voltage (typically 12V, 24V, or

Calculate Battery Size For Any Size Inverter

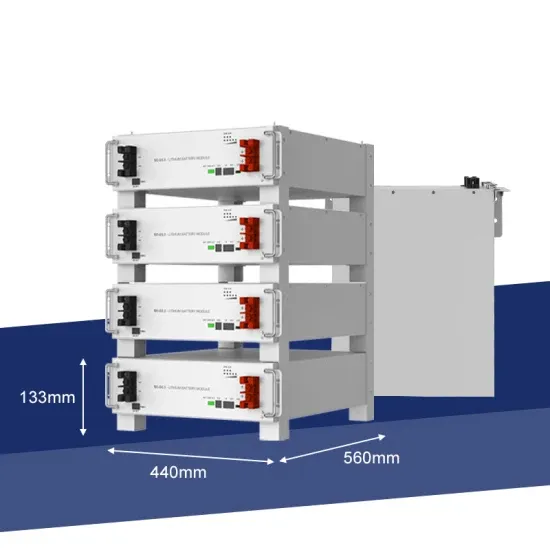

Mar 3, 2023 · Inverter capacity (W)*Runtime (hrs)/solar system voltage = Battery Size*1.15. Multiply the result by 2 for lead-acid type battery, for lithium battery

How to Know If Inverter Battery Fully Charged?

Aug 21, 2023 · For example, if the battery is fully charged, the voltage should be 11-13 V. If the voltmeter shows 13 volts, the battery is fully charged. If it reads

A Guide to Understanding Battery Specifications

Dec 18, 2008 · A battery is a device that converts chemical energy into electrical energy and vice versa. This summary provides an introduction to the terminology used to describe, classify,

A comprehensive guide to inverter voltage

Dec 18, 2024 · How to choose the inverter voltage? To select the best inverter for your application, it is important to match the inverter''s input and output voltage

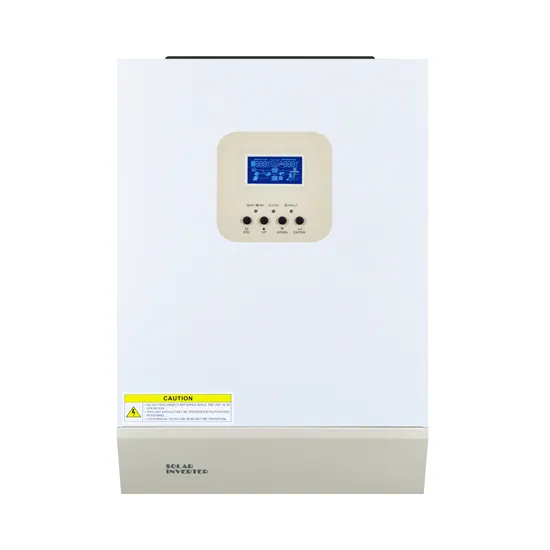

How to Easily Read the Parameters of Hybrid Inverters?

Jul 28, 2025 · In the world of renewable energy systems, the hybrid inverter stands as a central hub, orchestrating the intricate dance between solar power generation, battery storage, and

6. Controlling depth of discharge

Oct 23, 2024 · If the battery SoC falls below the SoC low-limit for more than 24 hours, it will be slow-charged (from an AC source) until the lower limit has been reached again. The dynamic

Exceeding Inverter Limits

Feb 2, 2020 · I''m looking to set up solar panels; the layout I am looking at will produce 264 Open Circuit Volts. My inverter specs read "250 Maximum PV Array Open Circuit Voltage" Would

Frequently Asked Questions about Inverters

Jan 10, 2024 · For a 12V inverter, the maximum input inverter voltage is typically around 16VDC. This safety margin provides a buffer to accommodate fluctuations in the power source and

Inverter DC ripple voltage specification

Mar 21, 2022 · This is presumably a major reason why Victron limit the ripple voltage at the inverter terminals, to avoid excessive heating of the input capacitors inside the inverter.

How to Select the Right Inverter and Battery for

Mar 14, 2025 · It is the total product of the maximum voltage and current that an inverter can feed without causing the inverter system to fail. The most

Inverter Peak Power vs Rated Power: What it is

Apr 21, 2025 · If the inverter''s maximum power is insufficient to meet this start-up demand, the unit may not start, even if the rated power is adequate. When

6 FAQs about [What is the maximum voltage of the inverter battery ]

What voltage should a 12V inverter run on?

The input voltage of the inverter should match the battery voltage. (For example 12v battery for 12v inverter, 24v battery for 24v inverter and 48v battery for 48v inverter Summary What Will An Inverter Run & For How Long?

How many volts does an inverter need?

For grid-tied systems, this is typically 220V or 230V in most countries. For off-grid systems, it might be 48V or 24V, depending on your battery configuration. Ensuring this rating matches your power system's output guarantees that your inverter will efficiently convert energy without risk of damage.

What is the input voltage of an inverter?

Understanding the inverter voltage is crucial for selecting the right equipment for your power system. Inverter voltage typically falls into three main categories: 12V, 24V, and 48V. These values signify the nominal direct current (DC) input voltage required for the inverter to function optimally. What is the rated input voltage of an inverter?

What is a maximum input voltage in a solar inverter?

The maximum input voltage defines the highest voltage the inverter can safely accept without causing damage. [Maximum input voltage] (Maximum input voltage in solar inverters) 2 indicates the upper voltage limit an inverter can handle. It’s crucial for ensuring long-term durability.

What is an example of a power inverter?

Common examples are refrigerators, air-conditioning units, and pumps. AC output voltage This value indicates to which utility voltages the inverter can connect. For inverters designed for residential use, the output voltage is 120 V or 240 V at 60 Hz for North America. It is 230 V at 50 Hz for many other countries.

What is maximum input voltage?

Maximum input voltage is the threshold that your inverter can handle without damage. This value is particularly important when integrating solar panels with varying output characteristics. If the solar array's voltage exceeds this limit, it can cause overheating, component failure, or even complete inverter damage.

Update Information

- What is the maximum watt inverter that can be used with a 12v 60A lithium battery

- What is the maximum voltage that a 48v inverter can connect to

- What is a voltage tracking PWM inverter

- What battery should I use for a 500w inverter

- What is the voltage of a semi-cylindrical lithium battery

- What kind of battery is in the inverter

- What is the price of dual voltage inverter

- What is the AC voltage of the inverter 220v

- Maximum voltage of photovoltaic inverter

- What does it mean to connect the inverter to a 12vdc battery

- What is the auxiliary power supply voltage of the inverter

- 24v lithium battery 300a with what size inverter

- 48v inverter maximum and minimum voltage

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.