Best 24v Trolling Motor Battery [Updated On: August 2025]

1 day ago · Top Recommendation: XZNY Compact 24V 100Ah Lithium Battery, 5000+ Cycles 24V Why We Recommend It: This battery boasts a 10-year lifespan, surpassing the others in

How to Choose the Right Inverter for Lithium Batteries?

Apr 11, 2025 · Lithium batteries require inverters with precise voltage compatibility (e.g., 12V, 24V, or 48V systems) and stable charging profiles. Unlike lead-acid batteries, lithium variants

What Size Inverter Do I Need for a 200AH Battery?

Dec 15, 2023 · To determine the appropriate inverter size for a 200AH battery, you need to consider the total wattage of the devices you plan to power. A general rule is to choose an

Buy Lithium Ion Inverter Battery At Best Price In

5 days ago · Buy UTL Lithium Ion inverter batteries at unbeatable price in India. It''s loaded with amazing features like fast charging, Zero maintenance, no

24V 314AH LiFePO4 Lithium Battery, Built-in Bluetooth 5.0 & 300A

Jun 3, 2025 · 24V 314AH LiFePO4 Lithium Battery, Built-in Bluetooth 5.0 & 300A BMS, Upgrade Aluminum Frame MAX 8038Wh Energy, 15000+ Deep Cycles Batterys, Perfect for Home

What Size Inverter Should I Use for My 24V, 206Ah Battery

May 21, 2025 · I have two 12V, 206Ah lithium iron phosphate batteries that I''ll connect in series, giving me a 24V, 206Ah setup. I''m considering either a 2000W or 3000W pure sine wave

What size fuse to use on my batteries? (24v system)

Nov 23, 2024 · My question is about fuse sizes on a 24v system. I have a pair of those WattCycle "300Ah" batteries in series. Besides the misnaming that Will uncovered, he notes the deficient

What size cables do I need

Apr 11, 2025 · Often the wire size is dependent not only on the rating of the device, but also the distance between the device and the batteries as voltage drop is the limiting factor. Devices

48V Inverter: The Ultimate Guide to Efficient and Scalable

May 19, 2025 · Unlock efficient power solutions with a 48V inverter—perfect for solar, off-grid, and backup systems. Learn how to choose the best one for your needs now!

Understanding Battery Capacity and Inverter Compatibility

Aug 20, 2024 · When pairing a 100 Ah lithium battery with a 1000 watt inverter, it is crucial to ensure compatibility to achieve optimal performance. Lithium batteries typically offer better

Best Trolling Motor Batteries For 24v [Updated On: August

1 day ago · For years, trolling motor batteries for 24V setups have often fallen short on durability and power stability, which is why I was excited to thoroughly test the latest options. After

24V 300Ah LiFePO4 Lithium Battery Box With Cells and BMS

Produce Name:24V 300Ah LiFePO4 Lithium Battery Box With Cells and BMS. Warranty:3 years. Material:Metal Product. Battery Type:Lithium lifepo4 Battery Pack. BMS:24V 8S 200A. BMS

BMS capacity vs fuse size

Apr 19, 2024 · Cruisers & Sailing Forums > Engineering & Systems > Lithium Power Systems BMS capacity vs fuse size « Cheap charger for "manual" emergency charging? Please read

Best internal BMS for 24V 300ah LiFePo4 battery

Apr 2, 2021 · Even my own systems, all use 300A Solid-State Contactor Based BMS'' but they will never exceed 200A draw unless it happens to be a momentary surge. 300A @ 24V is 7200W

What Size Inverter Can I Run Off a 100Ah Battery? A

Aug 13, 2024 · A 100Ah battery signifies its capacity to deliver 100 ampere-hours of current. This capacity influences how long an inverter can run appliances before needing a recharge.

6 FAQs about [24v lithium battery 300a with what size inverter]

How many lithium batteries do I need for a 3000 watt inverter?

The c-rate of lithium is 1. We can draw 100Ah x 1C = 100Amps. That is enough to power a 3,000 watt inverter without over-working the battery. You need to have 4 lithium batteries in series to power a 3,000 watt inverter. How many 100Ah batteries do I need for a 3000 watt inverter? You need 4 Lithium batteries in series to run a 3,000W inverter.

Which battery bank is best for a 24V 3000W inverter?

To keep your batteries operating safely and reliably, it is always recommended to go for a somewhat larger battery bank- generally, for lead-acid batteries 6 x 100Ah 24V battery Or 12 x 100Ah 12V battery is the smallest battery bank recommended for the 24V 3000W inverter.

What size inverter for a 200Ah battery?

To determine the appropriate inverter size for a 200Ah battery, consider the following: A 500VA inverter would be suitable, offering a balance between performance and battery life. For extended run times, consider larger inverters or additional batteries to meet higher power demands.

Which battery is best for a 1000 watt inverter?

Lead-acid batteries have a C-rate of 0.2C, while lithium (LiFePO4) batteries have a higher C-rate of 1C. 12V for inverters below 1000W. 24V for 1000-2000W inverters. 48V for 2000-4000W inverters. We need to satisfy two criteria before we can tell you what battery you need. These are:

Do lithium batteries work with inverters?

Lithium batteries typically offer better efficiency and longer life compared to lead-acid batteries. Inverter Efficiency: Lithium batteries generally work well with modern inverters, but checking the inverter’s efficiency rating is advisable. Efficiency impacts the actual power delivered to the devices.

Can a lithium battery run a 1000W inverter?

Battery Discharge Rate: Lithium batteries can handle high discharge rates, which aligns well with the power demands of a 1000W inverter. However, verify that the battery’s maximum discharge rate exceeds the inverter’s power draw. Temperature and Maintenance: Lithium batteries perform best within specific temperature ranges.

Update Information

- What size inverter should I use for a 150a lithium battery

- What is the charging voltage of a 24V lithium battery pack

- What size lithium battery is in the battery cabinet

- What is the maximum watt inverter that can be used with a 12v 60A lithium battery

- What is the appropriate size of battery inverter

- Burkina Faso off-grid lithium battery energy storage 20kw inverter

- Lithium battery power supply suitable for inverter

- How big an inverter should I use for a 12v 50A lithium battery

- Does the 60v inverter come with a lithium battery

- What is the price of Spanish cylindrical lithium battery

- Belgian square lithium battery size specifications

- What size inverter is suitable for 48 volts

- What is cp in lithium battery energy storage power station

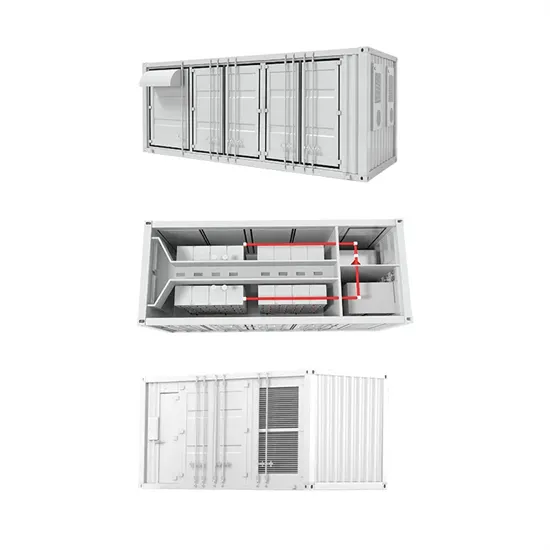

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.