Li-ion cell manufacturing: A look at processes

Jun 10, 2021 · The production of the lithium-ion battery cell consists of three main stages: electrode manufacturing, cell assembly, and cell finishing. Each of

LITHIUM-ION BATTERY CELL PRODUCTION PROCESS

The production of the lithium-ion battery cell consists of three main process steps: electrode manufacturing, cell assembly and cell finishing. Electrode production and cell finishing are

Servo Cylinder Applications in Lithium Battery Production

The Indispensable Role of Precision in Lithium Battery Manufacturing Battery safety and security and long life depend upon information you can barely see. Making lithium-ion batteries is a

Cylindrical Lithium Battery Production Process | JCT Machinery

JCT Machinery : The production process of cylindrical lithium battery involves multiple key links, each of which must be operated precisely to ensure the stability, long life and high energy

Cylinder Cell Production Line Lithium Ion Battery

5 days ago · It is mainly used for cylinder lithium battery automatic puting of the bottom insulator, battery core detection, putting battery core in the cases,

Lithium-ion Cylindrical Cell Manufacturing Process

Jul 25, 2023 · In this article, we will describe the production process of lithium-ion cylindrical batteries in detail. 1. Lithium-ion Battery Material Preparation. The

Making Module Lithium Battery Cylinder Production Line

Aug 8, 2025 · Making Module Lithium Battery Cylinder Production Line, Find Details and Price about Soft Pack Battery Battery Tab Cutting from Making Module Lithium Battery Cylinder

Cylindrical Cell manufacturing line

Apr 11, 2025 · What is a Cylindrical Cell Manufacturing Line? A Cylindrical Cell Manufacturing Line is an advanced industrial setup designed to mass-produce cylindrical lithium-ion batteries.

Cylindrical lithium battery classification and

May 17, 2023 · Cylindrical lithium batteries are divided into different systems of lithium iron phosphate,lithium cobaltate,lithium manganate,cobalt-manganese

Cylindrical Lithium Battery Production Line: Fully Automated

The cylindrical lithium battery production line is designed for manufacturing 18650, 21700, and other models of cylindrical lithium-ion batteries. This production line covers the entire process

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · Currently, the manufacturing of LIBs still needs to go through slurry mixing, coating, drying, calendering, slitting, vacuum drying, jelly roll fabrication (stacking for pouch cells and

Making Module Lithium Battery Cylinder Production Line

Jul 3, 2025 · Making Module Lithium Battery Cylinder Production Line, Find Details and Price about Battery Assembly Line Automobile Assembly Line from Making Module Lithium Battery

Everything about Cylindrical Batteries, the Power

May 29, 2024 · LG Energy Solution began its research on lithium-ion batteries in 1992. It launched the development of lithium-ion batteries in 1996 and entered

Design, Properties, and Manufacturing of

Jun 3, 2023 · The wetting of the active materials in a lithium-ion battery cell after electrolyte filling is a time-critical process in the manufacturing of lithium-ion

Cylinder Cell Automatic Assembly Line Equipment for Lithium Ion Battery

Jul 29, 2025 · Cylinder Cell Automatic Assembly Line Equipment for Lithium Ion Battery Making, Find Details and Price about Battery Production Line Battery Making Machine from Cylinder

Li/Na Battery Production – Cylindrical Battery

6 days ago · Application: semi-auto, fully auto cylindrical cell battery production line, full set production solution supplier; Warranty: One Year warranty with

Gelon Lithium-Ion Battery 18650 21700 32700 Cylinder Cell Battery

Aug 12, 2025 · Lithium Battery Production Line with One-stop Service and Turn-key Project for Pouch Cell Cylinder Cell Coin Cell 10 years exporting experience for Li-ion battery materials

6 FAQs about [Lithium battery cylinder production]

How are lithium-ion battery cells produced?

The production of lithium-ion battery cells includes four links: Pole piece production, cell assembly, cell formation, and battery packaging. The process is shown in Figure 1. Every process in the cell production process is very important.

What is the production process of lithium ion battery?

The production of cylindrical wound 18650 battery (capacity 1400mA h) and winding type 383450 battery (capacity 750mA·h) . The production of lithium-ion battery cells includes four links: Pole piece production, cell assembly, cell formation, and battery packaging. The process is shown in Figure 1.

How a lithium ion battery is formed?

Lithium-ion batteries must be formed, tested, and sorted before leaving the factory. The formation of lithium-ion batteries has two main functions: (1) The active material in the battery is converted into a material with normal electrochemical action by means of the first charge.

What is battery manufacturing process?

Figure 1 introduces the current state-of-the-art battery manufacturing process, which includes three major parts: electrode preparation, cell assembly, and battery electrochemistry activation. First, the active material (AM), conductive additive, and binder are mixed to form a uniform slurry with the solvent.

Does micro-level manufacturing affect the energy density of EV batteries?

Besides the cell manufacturing, “macro”-level manufacturing from cell to battery system could affect the final energy density and the total cost, especially for the EV battery system. The energy density of the EV battery system increased from less than 100 to ∼200 Wh/kg during the past decade (Löbberding et al., 2020).

Are lithium-ion batteries a viable energy storage solution?

Lithium-ion batteries (LIBs) have become one of the main energy storage solutions in modern society. The application fields and market share of LIBs have increased rapidly and continue to show a steady rising trend. The research on LIB materials has scored tremendous achievements.

Update Information

- Large cylinder of lithium battery

- Fully automatic lithium battery station cabinet production line

- Amsterdam lithium battery cylinder

- Production of lithium battery pack types

- Maldives lithium battery production company

- Lithium battery station cabinet production station power supply

- Lithium battery pack production cost

- Lithium battery cell large single cylinder

- 12v lithium battery cylinder in Antwerp Belgium

- Production of lithium iron phosphate battery pack

- Lithium battery top seal cylinder

- Replacement of lithium iron phosphate battery cabinet units at site

- Tuvalu energy storage lithium battery pack customization

Solar Storage Container Market Growth

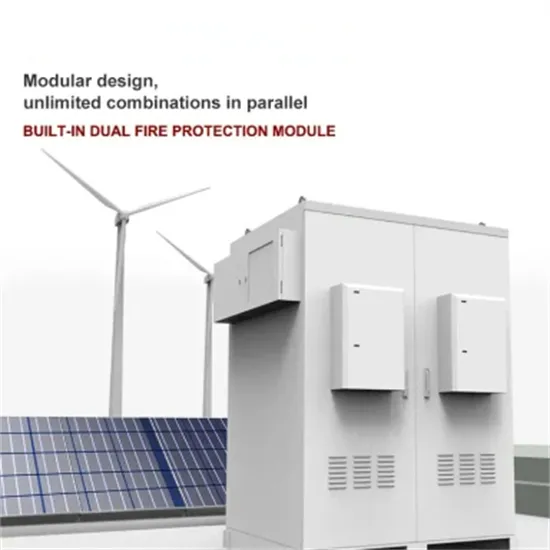

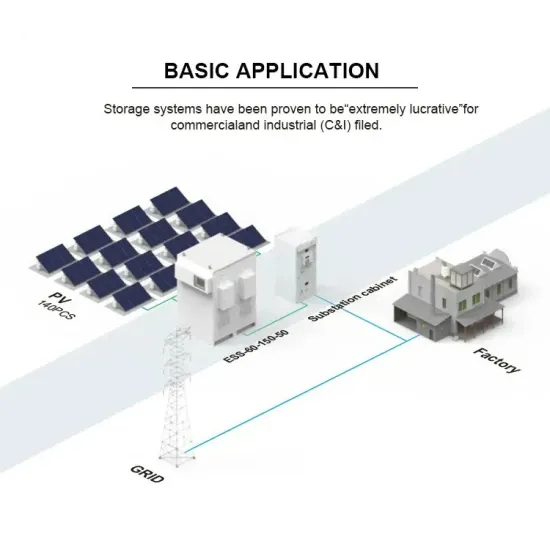

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.