Comparing Technical Criteria of Various Lithium-Ion Battery

Nov 10, 2020 · In this paper, the three most common formats for lithium-ion batteries (pouch, cylindrical and prismatic) are compared in terms of 19 defined technical criteria

Cylindrical lithium batteries and square lithium batteries

Mar 17, 2024 · Cylindrical lithium batteries and square lithium batteries each have their own advantages, the choice of which is better depends mainly on the specific application scenarios

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · The story of cylindrical lithium-ion battery cells traces back to the 1990s, when researchers pioneered the development of rechargeable lithium

Cylindrical lithium battery classification and

May 17, 2023 · Cylindrical lithium batteries are divided into different systems of lithium iron phosphate,lithium cobaltate,lithium manganate,cobalt-manganese

Pouch vs. Prismatic vs. Cylindrical? Your Lithium Battery Cell

Jul 29, 2025 · What''s the difference between pouch, prismatic, and cylindrical cells in lithium batteries? Read our guide to find the right battery cell type for your system.

Comparison between cylindrical lithium battery and square lithium

1. Battery shape: The square size can be designed arbitrarily, while the cylindrical battery cannot be compared. 2. Multiplication characteristics: the process limit for welding multipole lug of

Analysis of manufacturing processes of lithium batteries with

May 12, 2025 · In terms of manufacturing process complexity, square lithium batteries have the most complex manufacturing process and relatively high costs due to their structural design

Complete List of Cylindrical Lithium Battery Models.

Compared with soft pack and square lithium batteries, cylindrical lithium batteries have the longest development time, higher standardization, more mature technology, high yield rate, and low cost.

Introduction of the Cylindrical Lithium Ion Battery

Apr 13, 2023 · Cylindrical lithium ion batteries are divided into different systems of lithium iron phosphate, lithium cobalt oxide, lithium manganate, cobalt-manganese hybrid, and ternary

Analysis of Cylindrical Lithium Battery Advantages and

1. Definition of cylindrical lithium battery Cylindrical lithium battery is a kind of lithium ion battery, its shape is cylindrical, so it is called cylindrical lithium battery. The structure of a typical

The difference between cylindrical lithium batteries and square lithium

Cylindrical lithium batteries are divided into three different systems: lithium iron phosphate, lithium cobalt oxide, lithium manganese oxide, cobalt manganese mixture, and ternary materials.

Comparison of Square Lithium Battery, Cylindrical Lithium Battery

Apr 13, 2023 · Overall, no matter lithium prismatic battery, lithium cylindrical battery or pouch cell, the reason why at present they embrace the rapid development is that they are well

What are the structure and advantages and disadvantages of square

The structure of the prismatic battery is relatively simple, unlike the cylindrical battery, which uses high-strength stainless steel as the shell and has accessories such as explosion-proof safety

Prismatic Cells and Cylindrical Cells Compared

Feb 24, 2025 · There are three main varieties of lithium-ion batteries, namely prismatic, cylindrical, and pouch types. The first two battery types seem to be forging ahead of pouch

Comparatively Assessing different Shapes of Lithium-ion Battery

Jan 1, 2017 · Different shapes of lithium-ion batteries (LIB) are competing as energy storages for the automobile application. The shapes can be divided into cylindrical and prismatic, whereas

What Are Square Batteries and Their Characteristics?

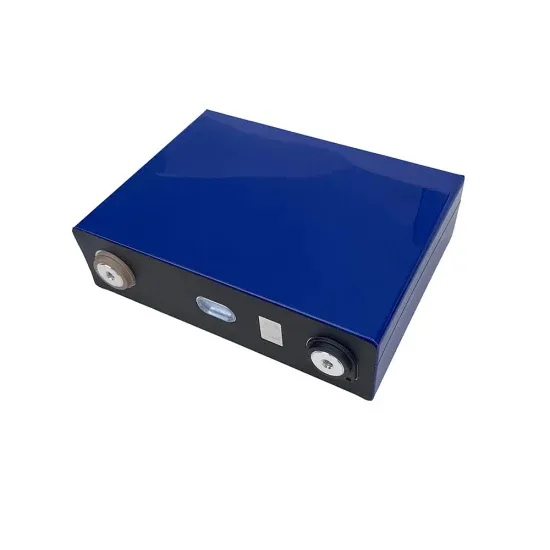

Apr 11, 2025 · Square batteries, also known as prismatic cells, are rectangular-shaped power sources with layered internal structures. Their flat design maximizes space efficiency, making

Square aluminum shell lithium-ion battery energy storage

Domestic power lithium battery manufacturers often use square aluminum shell lithium batteries with higher energy density because the structure of square lithium batteries is relatively

Update Information

- Cylindrical lithium battery and square

- Vilnius cylindrical lithium battery BESS

- Cylindrical lithium battery fixing

- Small square lithium battery

- Andorra City cylindrical lithium battery model

- Cylindrical secondary lithium battery charging method

- Cylindrical lithium battery assembly parts wholesale

- Georgia cylindrical lithium battery price

- The best cylindrical lithium battery cell

- Which type does a cylindrical lithium battery belong to

- Huawei cylindrical lithium battery model

- What is the capacity of a large cylindrical lithium battery

- Professional cylindrical lithium battery of different models

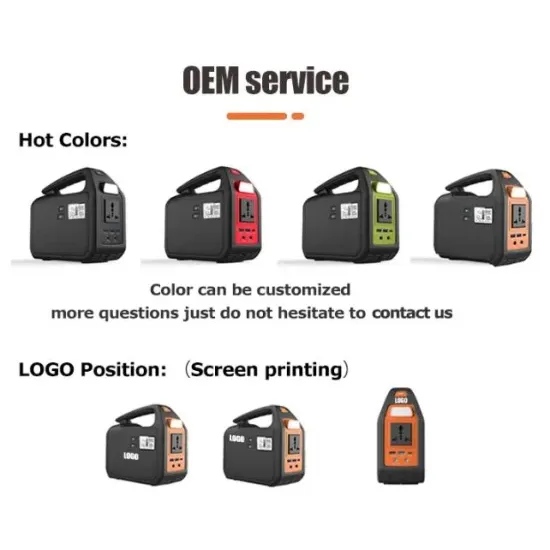

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.