Analysis of manufacturing processes of lithium batteries with

May 12, 2025 · In the new energy era, lithium batteries are the core power and energy storage unit, and their importance is self-evident. Among the many characteristics of lithium batteries,

Core Temperature Estimation for a Cylindrical Cell Battery

Sep 12, 2020 · Lithium ion (Li-ion) batteries in electric vehicle (EV) applications must operate within a narrow temperature range to ensure safety, performance and longevity. Hence,

Lumped-parameter temperature evolution model for cylindrical Li

Mar 1, 2021 · Integrating above achievements, two lumped TEMs for cylindrical li-ion batteries are constructed based on a second-order ECM. In Section 2, battery body is deemed as a

Performance assessment of a passive core cooling design for cylindrical

Mar 24, 2018 · Besides providing a proper temperature range for batteries to operate, thus improving their efficiency, lifespan, and safety, the BTM system also needs to be well designed

Optimal cell tab design and cooling strategy for cylindrical lithium

Apr 30, 2021 · In this work, a comprehensive electro-thermal model is developed for a cylindrical lithium-ion cell. The model is comprehensively parameterized and validated with experimental

Experimental estimation of core temperature and directional

May 1, 2025 · In this section, the battery core temperature for the cylindrical lithium-ion battery cell was estimated by using the thermal interrogation method. Because of this method is based on

Thermal Characterization of a Cylindrical Li-ion Battery Cell

Jul 31, 2025 · Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles,

Online Parameterization of Lumped Thermal Dynamics in Cylindrical

Castanier, Matthew P. "Online Parameterization of Lumped Thermal Dynamics in Cylindrical Lithium Ion Batteries for Core Temperature Estimation and Health Monitoring." IEEE

Design, Properties, and Manufacturing of Cylindrical Li

Jul 7, 2023 · This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design

Impact modeling of cylindrical lithium-ion battery cells: a

Oct 1, 2016 · In this study, a heterogeneous finite element model was developed in LS-DYNA to investigate lateral impact on 6P cylindrical lithium-ion battery cells

Size effect on the thermal and mechanical performance of cylindrical

Dec 1, 2024 · Abstract Increasing the size of cylindrical lithium-ion batteries (LIBs) to achieve higher energy densities and faster charging represents one effective tactics in nowadays

Lithium battery cylindrical model, cylindrical

Aug 1, 2025 · Unlike soft packs and square lithium batteries, cylindrical lithium batteries have the longest development time, higher standardization, more

A Structure of Cylindrical Lithium-ion Batteries

Jul 14, 2016 · Cylindrical Lithium-ion Batteries have been used in many electronic devices. The electrochemical cell of the batteries consists of a layer of positive electrode, a layer of negative

Internal Short Circuit Analysis of Cylindrical Lithium-Ion Cells

Mar 16, 2021 · Abstract Battery failures are obvious after being subject to abuse conditions however predicting these failures in advance is crucial when using test and validation

Large Cylindrical Battery Expand Ten Times More

May 22, 2025 · The fact that the volume change of large cylindrical battery far exceeds that of small cylindrical battery, with a difference exceeding tenfold.

Improving the cooling performance of cylindrical lithium-ion battery

Jun 5, 2023 · Developing a high-performance battery thermal management system (BTMS) to keep the temperature of lithium-ion battery (LIB) in a suitable range has be

Structural analysis and experimental characterization of cylindrical

Dec 20, 2014 · We report on modeling mechanical response of cylindrical lithium-ion battery cells that are commonly used in automotive applications when subjected to

Investigating thermal dynamics in cylindrical Li-ion batteries

4 days ago · Thermal dynamics in cylindrical Li-ion batteries, governed by electrochemical heat generation, are critical to performance and safety in high-power applications such as electric

Core collapse in cylindrical Li-ion batteries

Cylindrical lithium-ion batteries are manufactured with a jelly roll structure of tightly wound electrode layers separated by separators. Core collapse occurs when multiple layers adjacent

Lithium battery cylindrical model, cylindrical

Aug 1, 2025 · 1. What is a cylindrical lithium battery? 1. Definition of cylindrical battery Cylindrical lithium batteries are divided into lithium iron phosphate,

Lumped-Mass Model-Based State of Charge and Core

Oct 10, 2024 · Reliable estimation of the state of charge (SoC) and core temperature (CoT) of battery cells is paramount for formulating efficient energy and thermal managemen

Core collapse in cylindrical Li-ion batteries

Core collapse occurs when multiple layers adjacent to the core of the jelly roll deform inward. This paper reviews the experimental and stress modeling analysis studies of core collapse initiation

Design, Properties, and Manufacturing of Cylindrical Li

Jul 7, 2023 · In the last 3 years, cylindrical cells have gained strong relevance and popularity among automotive manufacturers, mainly driven by innovative cell designs, such as the Tesla

Development and evaluation of in-situ instrumentation for cylindrical

Apr 1, 2018 · However, in most use cases, especially in automotive applications, battery modules contain an array of tightly packed lithium-ion cells to meet specific power and energy

Parameterization of Lumped Thermal Dynamics in Cylindrical Lithium

Lithium ion batteries should always be prevented from overheating and hence thermal monitoring is indispensable. Since only the surface temperature of the battery can be measured, a

Core collapse in cylindrical Li-ion batteries

Dec 15, 2024 · Cycle-dependent irreversible changes are critical for core collapse initiation. Cylindrical lithium-ion batteries are manufactured with a jelly roll structure of tightly wound

Cylindrical lithium ion battery manufacturing process

The cylindrical lithium ion battery is a battery structure in which a positive electrode, a negative electrode, and a separator are wound to form a cylindrical roll core structure and are sealed by

Online core temperature estimation method for lithium-ion batteries

Jan 30, 2025 · Online monitoring of the core temperature in Lithium-ion batteries (LIBs) is essential for effective thermal management and risk prevention. Throughout the lifecycle of

Comparative analysis of cylindrical lithium-ion battery

Aug 1, 2025 · With the widespread application of electric vehicles, energy storage systems, and portable electronic devices, lithium-ion batteries, particularly cylindrical cells, have become a

6 FAQs about [Cylindrical lithium battery core]

What is a cylindrical lithium ion battery?

Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles, and energy storage systems. They are characterized by their cylindrical shape, standardized sizes, and high energy density, making them versatile and suitable for various applications.

How do you identify a cylindrical lithium-ion battery?

For instance, “65” represents a height of 65mm. Fifth Digit: The fifth digit indicates the cylindrical shape of the cell. Typically, it’s “0” for cylindrical cells. By following this naming convention, we can easily identify the size and shape of cylindrical lithium-ion battery cells.

What is a cylinder Li-ion battery?

Cylindrical Li-ion battery cells consist of (i) a jelly roll, a wound composite consisting of a cathode, an anode, and two separators, and (ii) a cell housing consisting of a can and a cap . Current and heat transport between the jelly roll and the cell housing is traditionally conducted by contacting elements called tabs .

Why are cylindrical battery cells so popular?

In the last 3 years, cylindrical cells have gained strong relevance and popularity among automotive manufacturers, mainly driven by innovative cell designs, such as the Tesla tabless design. This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680).

What are the naming rules for lithium ion batteries?

The naming rules for cylindrical lithium-ion battery cells follows a standardized format based on the cell’s dimensions, and usually represented by a five-digit code, where each digit provides specific information about the cell’s dimensions. Here’s a breakdown of the representation: What does 18650 means?

What are battery cells?

Battery Cells—A Generic Overview. Copyright: 2023 by the authors. Licensee MDPI, Basel, Switzerland. 4.0/). Abstract: Battery cells are the main components of a battery system for electric vehicle batteries. Depending on the manufacturer, three different cell formats are used in the automotive sector (pouch, prismatic, and cylindrical).

Update Information

- 3 4v8000ma cylindrical lithium battery

- Lithium battery cylindrical technology

- Lithium battery cylindrical to nickel

- Professional cylindrical lithium battery of different models

- The best cylindrical lithium battery cell

- Lithium battery assembly cylindrical

- Azerbaijan cylindrical lithium battery model

- The smallest cylindrical rechargeable lithium battery

- Difference between Chilean lithium battery and cylindrical battery

- Marshall Islands cylindrical lithium battery 7260

- Lithuania s largest cylindrical lithium battery

- Asuncion cylindrical lithium battery custom manufacturer

- Mongolian cylindrical lithium battery is a battery

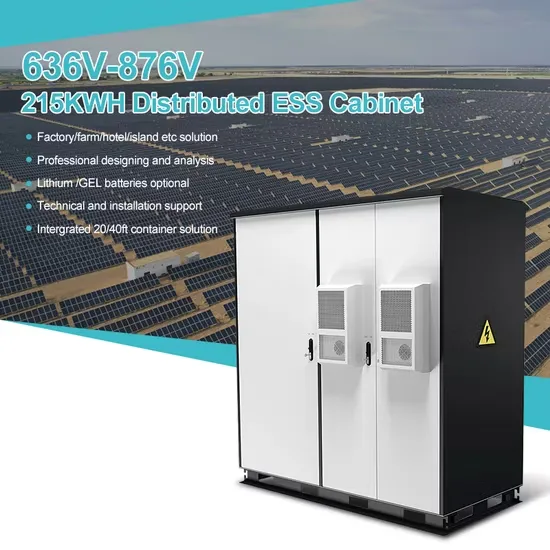

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.