2020_04_29_Infineon_Dual_Inverter_Whitepaper dd

Sep 2, 2020 · The dual inverter incorporates a Vehicle Management Unit (VMU), which monitors driver inputs such as key and start/stop switch, accelerator pedal position, brake pedal

Efficiency-Optimized High-Current Dual Active Bridge

Aug 6, 2019 · Efficiency-Optimized High-Current Dual Active Bridge Converter for Automotive Applications Florian Krismer, Student Member, IEEE, and Johann W. Kolar, Fellow, IEEE

Dual Voltage–Current Control to Provide Grid-Forming Inverters

Dec 7, 2021 · As the semiconductors used in power electronics are highly sensitive to overcurrents, this article proposes a dual voltage–current control that provides the grid-forming

Design and Implementation of Dual Voltage Source

Dec 27, 2017 · inverter. This in turn reduces the dc-link voltage requirement of the main inverter. Thus, the use of two separate inverters in the proposed DVSI scheme provides increased

SN74LVC2G04 Dual Inverter Gate datasheet (Rev

Jun 19, 2025 · 10 Power Supply Recommendations The power supply can be any voltage between the min and max supply voltage rating located in the Recommended Operating

RS2G14 Dual Schmitt-Trigger Inverter

Mar 26, 2024 · The RS2G14 device contains two inverter and performs the Boolean function Y= A̅ . The device functions as two independent inverters with Schmitt-trigger inputs, so the device

VEVOR MMA Welder, 205A 2-in-1 MMA Lift TIG Stick

Mar 6, 2025 · 2-in-1 MMA Welder: This 205A MMA welder supports MMA/Stick welding and Lift TIG modes, ideal for home DIY, garage workshops, and car repairs. PLEASE NOTE: The TIG

EV Traction Motor Power Inverter Control Reference

Aug 25, 2022 · This reference design is a high-voltage inverter solution implemented for hybrid electric vehicle and electric vehicle traction control systems. It includes efficient system

Inverter Transformers for Photovoltaic (PV) power plants:

Dec 22, 2022 · In this paper, the author describes the key parameters to be considered for the selection of inverter transformers, along with various recommendations based on lessons

DUAL VOLTAGE SOURCE INVERTER USING HYBRID

Jun 7, 2023 · A 300-W experimental prototype is tested at 25-35-V input voltage, 155 V peak output voltages, and 50 kHz. Zhu et al.[9] propose a single-phase boost inverter with reduced

Understanding Split Phase Inverters: A Complete Guide

Mar 17, 2025 · The former gives you dual voltage outputs (120V and 240V). This means they can handle both low and high power needs; single phase inverters only give one voltage, limiting

DUAL VOLTAGE SOURCE INVERTER USING HYBRID

Jun 7, 2023 · Aghazadeh et al.[2] proposed a dual two-level voltage-source inverter (DTL VSI) to integrate two dc sources into the MIACDC power architecture of fully integrated power and

A Novel Dual-Input Split-Source Multilevel Inverter With

Nov 9, 2024 · A Novel Dual-Input Split-Source Multilevel Inverter With Single-Stage-Integrated Dynamic Voltage-Boosting Feature for Hybrid Energy Storage in Transportation Systems |

3.5kW, 10kW or 20kW Inverter: Recommendations for

A HWOO 3.5kW inverter is suitable for smaller homes or those with lower energy consumption, while a 10kW inverter is ideal for medium-sized households. For larger homes or those with

Dual‐Boost Inverter Without Leakage Current

Nov 13, 2024 · The output AC side voltage of traditional full-bridge inverter is lower than the input DC side voltage, which is limited in low-voltage power generation. The conventional boost

Solar Inverter TOP

Sep 9, 2021 · The output of the boost converter is an elevated and regulated DC voltage. Isolated, precision voltage sensors are placed on this node feeding back to control/MCU to modulate

6 FAQs about [Dual voltage inverter recommendation]

How does a dual inverter work?

The dual inverter incorporates a Vehicle Management Unit (VMU), which monitors driver inputs such as key and start/stop switch, accelerator pedal position, brake pedal position, steering angle, drive mode selector along with other vehicle status information communicated over CAN bus.

What are the efficiencies of the proposed inverter?

The efficiencies of the proposed inverter and those in previous works have been shown in Table 7. In this comparison, it should be considered that the proposed inverter is a single-stage, high voltage gain, microcontroller-based inverter which takes advantage from machine intelligence in its protection procedure.

What are the advantages of a power inverter?

These inverters have notable features such as being short-circuit risk-free, not requiring connection to the AC grid for stable output voltage, minimizing voltage and current stress, having higher voltage gain, continuous input current, and excellent power-sharing capabilities.

Can a dual inverter drive a single six-phase motor?

The two independent inverter three-phase outputs could optionally be used to drive a single six-phase motor or paralleled for a single higher power three-phase motor drive. The dual inverter control logic is supplied by a 12V supply, while the 3-phase bridge is connected to the 48V battery by means of cable lugs.

What is a dual-source inverter?

This paper is an attempt to provide a dual-source inverter, an intelligent inverter topology that links two isolated DC sources to a single three-phase output through single-stage conversion. The converter is designed to be utilized in hybrid photovoltaic fuel cell systems, among other renewable energy applications.

What is a dual-input dual-output inverter?

Reference 14 describes a dual-input dual-output inverter with nine switches, allowing each source to supply a separate load. In the topology presented in Ref. 15, the input sources cannot have random voltage or current levels. Two dual-input single-output three-phase inverters are discussed in Refs. 1, 2.

Update Information

- What does dual voltage inverter mean

- Is dual voltage inverter good

- Intelligent universal dual voltage 24v220v inverter

- What is the price of dual voltage inverter

- Energy storage elements of voltage inverter

- Working function of high voltage inverter

- Inverter generator adjusts voltage

- Inverter capacitor ripple voltage

- Photovoltaic high voltage inverter

- Processing high voltage inverter

- Three-phase voltage type pwm inverter design

- The role of variable voltage inverter

- Ecuador Inverter DC Voltage Wholesale

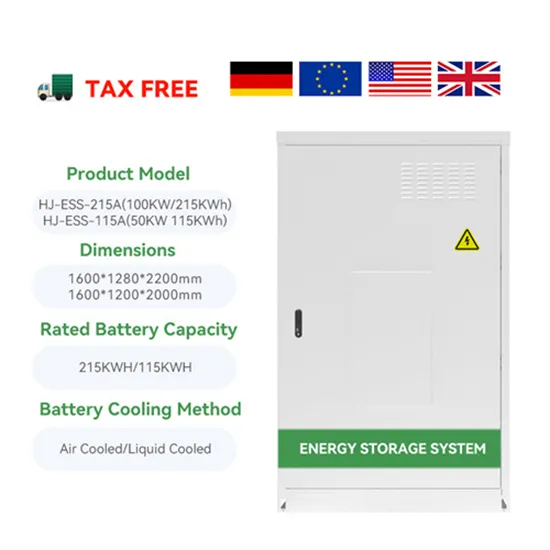

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.