The Lithium Battery Assembly Process and Advantages

Considering the growing demand for electric vehicles and stationary energy storage systems, lithium batteries are rapidly becoming an essential part of modern life. lithium battery assembly

How to Build a 12V Lithium-Ion Battery Pack: A

Jan 19, 2025 · Building a 12V lithium-ion battery pack is an essential skill for electronics enthusiasts and DIYers alike. Whether you want to power a small robot or create a portable

Specification parameters of the 12V lithium-ion battery. Assembly

Jul 12, 2025 · Specification Parameters of the 12V Lithium-ion Battery: A Comprehensive Guide for Optimal Performance When selecting a 12V lithium-ion battery for your

12v energy storage lithium battery assembly

Jun 18, 2023 · Lithium-ion batteries have become a go-to option for energy storage in solar systems, but technology has advanced, a new winner in the race for energy storage solutions

Lithium Battery Production & Application Video Library

Aug 16, 2025 · high-quality lithium battery product videos in industrial and lab settings, showcasing assembly, applications, and technical insights for electronics and energy storage

Building 12V Battery Packs with 18650 Cells: A Guide

Jun 8, 2024 · Ensure balanced charging and consider using protective cases for safety and longevity. Building 12V Battery Packs with 18650 Cells: A Step-by-Step Guide Creating a 12V

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · Assembling a lithium battery pack is a critical skill for anyone working with modern energy storage systems. Whether you''re powering an electric vehicle, a renewable energy

12V 200Ah Lifepo4 Battery Assembly For Off

Jul 22, 2025 · A solar battery is a device that is charged with energy from Solar panels. Batteries can store the electricity generated in the daytime. 12V 200Ah

11 Leading China Lithium Battery Manufacturers

Aug 18, 2025 · DEFORD batteries deliver 500-1,000 charge cycles for lithium-ion chemistry and 2,000-3,000 cycles for LiFePO4 variants, with both maintaining 70-80% capacity at end-of-life.

How to make a 12 volt lithium-ion battery pack?

Nov 14, 2024 · Building a 12V lithium-ion battery pack can be a rewarding DIY project, providing you with a reliable power source for various applications. To

How to Make a 12V 100Ah Lithium Battery?

Jun 19, 2025 · Lithium-ion batteries, particularly the 12V 100Ah lithium battery, have become a cornerstone in modern energy storage solutions due to their efficiency, lightweight design, and

Building a 12v 60Ah Battery Pack – Step by Step!

Jun 19, 2025 · The Daly K-Series Smart BMS is a powerful and intelligent Battery Management System designed for lithium iron phosphate (LiFePO₄) and lithium-ion batteries. It supports 3S

How to Build a Lithium Ion Battery Pack? A Step by Step

Apr 9, 2025 · Below is a list of materials and tools that need to be prepared in how to build a lithium ion battery pack that is efficient and safe. Select the appropriate battery cells, such as

How to Build a 12V-48V 230Ah LiFePO4 Battery Pack for DIY

Apr 10, 2025 · Building a 12V-48V 230Ah LiFePO4 battery pack involves connecting 8 Grade A 3.2V cells in series/parallel configurations. These cells are ideal for boats, RVs, and solar

Full Tutorial of DIY A 12V 50Ah LiFePO4 Battery

Aug 15, 2025 · If you need a small voltage and capacity of LiFePO4 battery pack, the 12V 50Ah one is worth a try. Here is the tutorial on the 12V 50Ah LiFePO4

Li-ion cell manufacturing: A look at processes

Jun 10, 2021 · The production of the lithium-ion battery cell consists of three main stages: electrode manufacturing, cell assembly, and cell finishing. Each of

12V Battery Pack 18650, From Assembly to Application

Apsenx 12V 18650 battery packs, built to military-grade standards, offer global users a safer, more efficient, and smarter energy storage solution. Contact us today for your customized power

6 FAQs about [12v energy storage lithium battery assembly]

What materials do I need to build a 12V lithium battery pack?

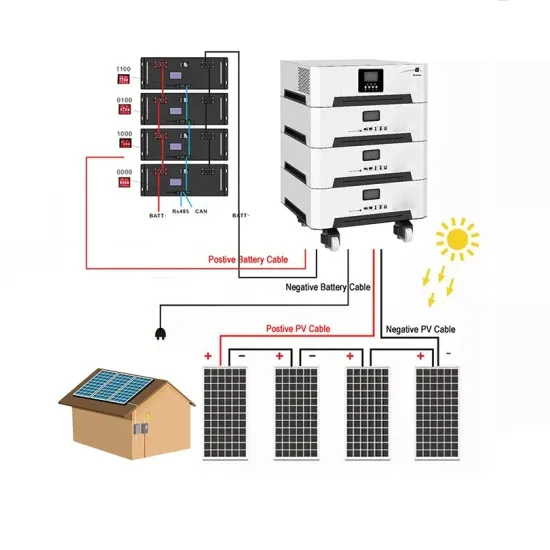

To build a 12V lithium battery pack, you will need the following materials: Wholesale lithium golf cart batteries with 10-year life? Check here. Lithium-Ion Cells: Commonly used cells include 18650 or LiFePO4 cells. Battery Management System (BMS): This device monitors and manages the charging and discharging of the battery.

How do I assemble a 12V battery pack?

Assembling your battery pack involves several steps: Determine Configuration: For a 12V pack, connect cells in series. Typically, you will need four cells in series if using LiFePO4 (3.2V per cell) or three cells if using standard lithium-ion cells (3.7V per cell).

What is lithium ion battery assembly?

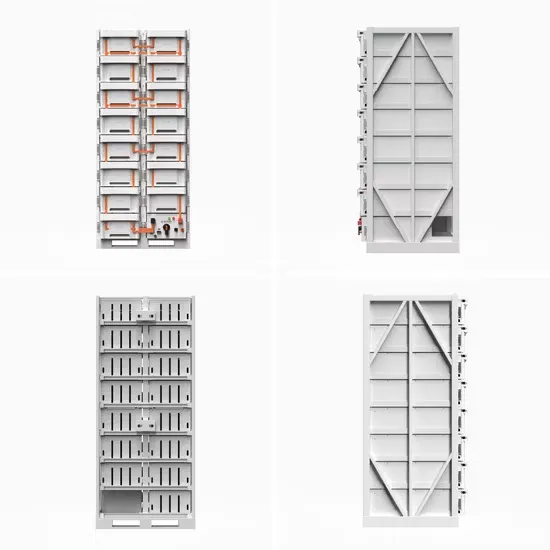

Lithium-Ion Battery Assembly: Involves stacking layers of anodes, cathodes, and separators. Assembly techniques include winding for cylindrical cells and stacking for prismatic cells. Requires careful handling of liquid electrolytes during assembly. Lithium Polymer Battery Assembly:

What is a lithium ion battery?

Composition: Lithium-ion batteries (Li-ion) use lithium compounds as electrolytes, allowing ions to move between the anode and cathode during charging and discharging. Structure: Typically cylindrical or prismatic, manufacturers widely use them in consumer electronics, electric vehicles, and energy storage systems.

What is battery assembly?

Battery assembly is the process of assembling parts to create a functioning battery. This involves combining essential components like cells and connectors. Using the right tools and following precise steps is necessary to ensure the battery works properly.

What is a lithium battery management system (BMS)?

The cells within a lithium battery pack are typically arranged in series or parallel configurations to achieve the desired voltage and capacity. Additionally, a Battery Management System (BMS) is often integrated to monitor and ensure the safe operation of the battery pack.

Update Information

- Liberia Energy Storage Lithium Battery Assembly Company

- New Zealand high voltage energy storage lithium battery assembly

- Lithium iron phosphate single 12v energy storage battery

- 12V household energy storage lithium battery

- Norway energy storage lithium battery assembly plant

- Dubai Energy Storage Lithium Battery

- Lithium battery site cabinet energy storage liquid cooling

- 500V lithium battery energy storage system

- Photovoltaic energy storage lithium battery in Manchester UK

- Kyrgyzstan ups energy storage lithium battery manufacturer

- Laayoune lithium battery energy storage cabinet 215KWh

- Grid Energy Storage Lithium Battery

- Jamaica energy storage lithium battery cell

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.