What types of solar glass are there | NenPower

May 3, 2024 · 1. LOW-IRON GLASS Solar panels depend heavily on the properties of the glass that covers the photovoltaic (PV) cells. Low-iron glass stands out due to its unique attributes,

Glass Solar Panels: Tomorrow''s Energy System

Jan 6, 2023 · Glass solar panels can help reduce electricity bills. Learn how solar windows turn sunlight into renewable energy and if we should start investing in it.

Low Iron Solar Glass Market Size, Growth Statistics

The superior optical properties of low iron solar glass make it an essential component in photovoltaic modules, solar thermal collectors, and building-integrated photovoltaic systems.

Solar Glass: applications and comparison to Light-Trapping

Solar Glass is one of the crucial barriers of traditional solar panels protecting solar cells against harmful external factors, such as water, vapor, and dirt. For what type of solar panels is glass

VGC 3.2mm Mistlite ARC Tempered Middle-Iron

Jul 13, 2025 · What is Middle-Iron Pattern Glass? Middle-Iron Pattern Glass is a type of glass that is specifically designed for use in solar applications, such as

Jiangyin Shenglite new energy Co., Ltd.-Photovoltaic Tempered Glass

Jiangyin Shengliti New Energy Co., Ltd. is a manufacturer of solar photovoltaic glass. The main products are tempered glass of various sizes, anti-reflective glass, double-module sheet glass,

Solar Glass & Mirrors, Photovoltaics | Solar Energy

Iron Impurities: Most glass contains iron impurities in the form of iron salts within the silicon oxide that impair tthe transmission of light through the material. Sources for low iron glass include

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · Glass-glass encapsulation, low-iron tempered glass, and anti-reflective coatings improve light management, durability, and efficiency. Advances in glass compositions, including

Glass in Solar Panels: The Clear Key to Clean Energy

Apr 17, 2025 · The glass used on solar panels is designed to be super clear, with low iron content to reduce any greenish tint or fogginess. This means more sunlight gets through to the PV

What Kind of Glass is Used for Crystalline Silicon

Mar 26, 2020 · Solar photovoltaic glass is used as a surface encapsulation and protection material for solar panels which plays key role for the long-term use

VGC 3.2mm Mistlite ARC Tempered Middle-Iron

Jul 13, 2025 · VGC Middle-Iron Pattern Glass is a type of glass that is specifically designed for use in solar applications, such as solar panels or photovoltaic

Photovoltaic glass: the perfect fusion between

Aug 18, 2025 · Photovoltaic glass is transparent solar panels designed to replace conventional glass in buildings and structures. These panels are capable of

6 FAQs about [Iron content of photovoltaic tempered glass]

How much iron is in solar glass?

Therefore, strict requirements are imposed on the iron content in the silicon raw materials used for producing solar glass, with Fe2O3 content typically ranging from 140 to 150 ppm. According to reports, Germany was the first country to use transparent flat glass as a substrate for developing solar cells.

What is Solar Photovoltaic Glass?

This article explores the classification and applications of solar photovoltaic glass. Photovoltaic glass substrates used in solar cells typically include ultra-thin glass, surface-coated glass, and low-iron (extra-clear) glass.

What are the characteristics of glass for solar applications?

For solar applications the main attributes of glass are transmission, mechanical strength and specific weight. Transmission factors measure the ratio of energy of the transmitted to the incoming light for a specific glass and glass width. Ratio of the total energy from an AM1-5 source over whole solar spectrum from 300 - 2,500nm wavelength.

Does glass have iron impurities?

Iron Impurities: Most glass contains iron impurities in the form of iron salts within the silicon oxide that impair tthe transmission of light through the material. Sources for low iron glass include low iron sand and limestone. To produce low iron flass, furnaces must be designed to handle higher melting and refining temperatures.

Which materials are used in photovoltaic panels?

The remaining 20 –25% encompassed fiberglass (including reinforcement, insulation, and mineral wool fibers) and specialty glass manufacturing . Flat glass transparency, low-iron glass improves photovoltaic (PV) panel efficiency. This seg- emphasis on energy efficiency and sustainability. Refs. [35, 36].

Which type of glass is best for solar panels?

This type of glass is more transparent and can significantly enhance the amount of light reaching the photovoltaic cells, thus boosting the overall efficiency of the solar panel. Low-iron glass is especially beneficial in high-performance solar panels where maximizing light transmission is critical.

Update Information

- Athens Group Photovoltaic Tempered Glass

- Photovoltaic tempered glass equipment

- Photovoltaic glass factory tempered price

- What is photovoltaic tempered glass

- Does photovoltaic glass have any content

- Tempered glass photovoltaic sun room

- How much does a photovoltaic tempered glass cost

- Photovoltaic tempered glass transportation standards

- Photovoltaic glass installation in Dominican sun room

- EK Photovoltaic Glass Transportation

- Is double glass in photovoltaic modules conductive

- Huawei Photovoltaic Glass Conveyor Belt

- How much does Niger s energy-saving photovoltaic glass cost

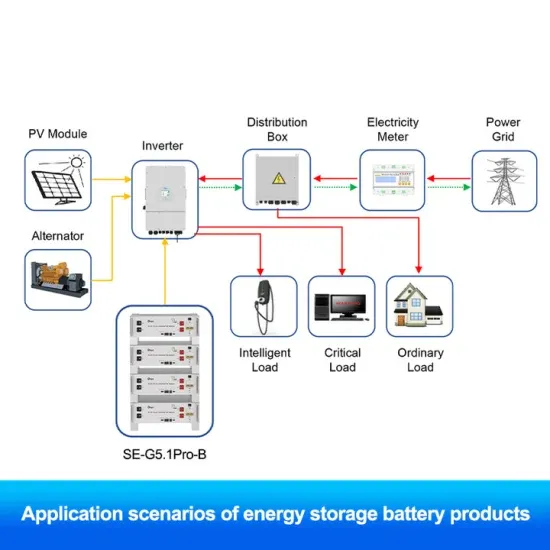

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

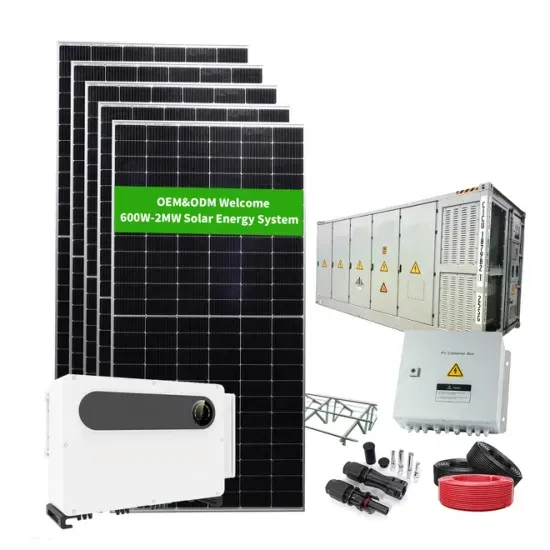

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.