Increasing Hydraulic Energy Storage Capacity: Flywheel-Accumulator

Nov 1, 2009 · The hydraulic flywheel accumulator is a novel energy storage device that has the potential to overcome major drawbacks of conventional energy storage methods for mobile

Flywheel Systems for Utility Scale Energy Storage

Apr 6, 2022 · An early unit from the project, an M25 with a power capacity of 6.25kW and 25kWh energy storage capacity flywheel, was temporarily sent to a site in Subic Bay Philippines by

Evaluating the Characteristics of Flywheel and Hydraulic Energy Storage

Hydraulic energy storage systems are also more cost-effective than flywheel energy storage systems due to their use of off-the-shelf components. They also have a higher energy storage

Flywheel energy storage—An upswing technology for energy

May 1, 2007 · Flywheel energy storage (FES) can have energy fed in the rotational mass of a flywheel, store it as kinetic energy, and release out upon demand. It is a significant and

Advancing renewable energy: Strategic modeling and

Nov 1, 2024 · Abstract This study introduces a hybrid energy storage system that combines advanced flywheel technology with hydrogen fuel cells and electrolyzers to address the

Strategies to improve the energy efficiency of hydraulic

Request PDF | On Mar 1, 2023, Xiaopeng Yan and others published Strategies to improve the energy efficiency of hydraulic power unit with flywheel energy storage system | Find, read and

A review of energy storage technologies in hydraulic wind

Jul 15, 2022 · This article mainly reviews the energy storage technology used in hydraulic wind power and summarizes the energy transmission and reuse principles of hydraulic

Strategies to improve the energy efficiency of hydraulic

To cope with this problem, this paper proposes an energy-recovery method based on a flywheel energy storage system (FESS) to reduce the installed power and improve the energy

Hybrid Vehicle Using Constant Pressure Hydraulic System with Flywheel

Jan 1, 2010 · Shimoyama et al. and Cronk et al. proposed an energy storage solution with a flywheel coupled to a variable displacement pump/motor shaft in a series hydraulic hybrid

Various Concepts on Variable Inertia Flywheel in Rotating

Jun 8, 2023 · Variable inertia flywheel is an innovative approach for storing energy in a rotating system. It may replace the constant inertia flywheel effectively from the conventional rotating

Prototype production and comparative analysis of high-speed flywheel

Nov 1, 2021 · A flywheel is a mechanical kinetic energy storage system; it can save energy from the systems when coupled to an electric machine or CVT [30]. Most of the time, driving an

Research on Magnetic Coupling Flywheel Energy

The flywheel energy storage device has no energy exchange with the vehicle. When the vehicle starts to brake, the magnetic ring begins to move to the right, and the driven shaft is gradually

The Status and Future of Flywheel Energy Storage

Jun 26, 2019 · Outline Flywheels, one of the earliest forms of energy storage, could play a significant role in the transformation of the electri-cal power system into one that is fully

Flywheel energy storage systems and their application with

Nov 18, 2021 · The rising demand for continuous and clean electricity supply using renewable energy sources, uninterrupted power supply to responsible consumers and an increas

Design optimization, construction, and testing of a hydraulic flywheel

Dec 1, 2021 · The hydraulic flywheel accumulator is a dual domain energy storage system that leverages complimentary characteristics of each domain. The system involves rotating a

Flywheel-Accumulator for Compact Hydraulic Energy

Apr 29, 2010 · A solution to bridge this gap is to improve the energy storage per unit mass of a hydraulic accumulator by storing energy as potential and rotating kinetic energy in a flywheel

A review of hydro-pneumatic and flywheel energy storage

摘要: This review will consider the state-of-the art in the storage of mechanical energy for hydraulic systems. It will begin by considering the traditional energy storage device, the hydro

Strategies to improve the energy efficiency of hydraulic power

Mar 1, 2023 · To cope with this problem, this paper proposes an energy-recovery method based on a flywheel energy storage system (FESS) to reduce the installed power and improve the

A Numerical and Experimental Study of Flywheel Energy Storage

It then explores various mobile hydraulic flywheel topologies and their control strategies when applied to a hydraulic hybrid truck. To understand and model the HFA this study presents an

Pumped Hydro-Energy Storage System

Pumped hydro energy storage system (PHES) is the only commercially proven large scale (> 100 MW) energy storage technology [163]. The fundamental principle of PHES is to store electric

A Study of Hydraulic Hybrid Vehicle Topologies with Flywheel Energy Storage

Nov 7, 2017 · This analysis reveals that energy loss behavior in the hydraulic pump/motors is dominating, that 3 hydraulic pump/motor topologies are more efficient due to their effect on

Energy recovery for hybrid hydraulic excavators: flywheel

May 1, 2021 · Abstract Hybridization is an effective method to reduce fuel consumption and emissions of toxic pollutants generated by hydraulic excavators (HEs). This paper first reviews

Role of Flywheel Batteries in Energy Storage System

Jun 4, 2022 · A flywheel stores mechanical energy that is converted to electrical energy by an electrical machine with a reciprocal power converter in flywheel-based energy storage systems.

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Energy storage flywheels are usually supported by active magnetic bearing (AMB) systems to avoid friction loss. Therefore, it can store energy at high efficiency over a long

Modeling, Optimization, and Detailed Design of a Hydraulic Flywheel

At both scales, the optimization results suggest that the hydraulic flywheel-accumulator offers at least an order of magnitude improvement over traditional static accumulator energy storage,

Comparison and Influence of Flywheels Energy Storage

Mar 31, 2022 · Increased renewable energy penetration in isolated power systems has a clear impact on the quality of system frequency. The flywheel energy storage system (FESS) is a

A review of hydro-pneumatic and flywheel energy storage for hydraulic

Aug 14, 2025 · This review will consider the state-of-the art in the storage of mechanical energy for hydraulic systems. It will begin by considering the traditional energy storage device, the

6 FAQs about [Flywheel energy storage hydraulic]

What is a flywheel energy storage system?

Flywheel energy storage systems have gained increased popularity as a method of environmentally friendly energy storage. Fly wheels store energy in mechanical rotational energy to be then converted into the required power form when required. power delivery system.

What is a flywheel/kinetic energy storage system (fess)?

Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently.

Can flywheel energy storage be commercially viable?

This project explored flywheel energy storage R&D to reach commercial viability for utility scale energy storage. This required advancing the design, manufacturing capability, system cost, storage capacity, efficiency, reliability, safety, and system level operation of flywheel energy storage technology.

How do fly wheels store energy?

Fly wheels store energy in mechanical rotational energy to be then converted into the required power form when required. Energy storage is a vital component of any power system, as the stored energy can be used to offset inconsistencies in the power delivery system.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

Are flywheel batteries a good option for solar energy storage?

However, the high cost of purchase and maintenance of solar batteries has been a major hindrance. Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power density and a low environmental footprint.

Update Information

- Flywheel system energy storage device composition

- Construction of flywheel energy storage project for communication base station in Tajikistan

- What is flywheel energy storage produced with

- What is the flywheel energy storage of Iceland s communication base stations like

- Flywheel energy storage photovoltaic battery for communication base station

- Huawei s flywheel energy storage business model

- Superconducting flywheel energy storage and flywheel rotor

- Afghanistan communication base station flywheel energy storage

- Sana flywheel energy storage device

- Key flywheel energy storage companies

- Flywheel Energy Storage Group Standard

- Lebanon communication base station flywheel energy storage equipment

- Hungarian power plant flywheel energy storage company

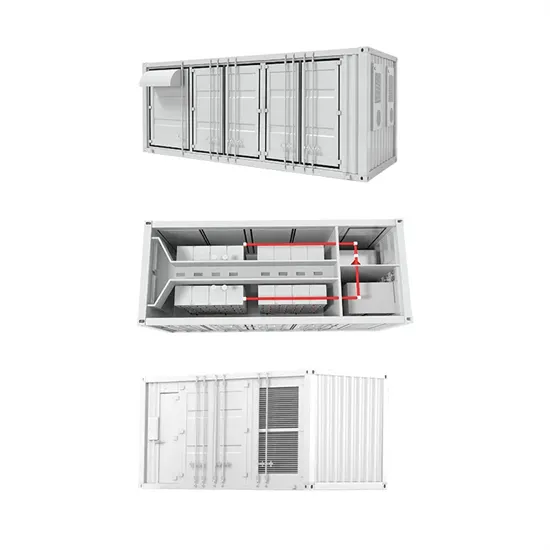

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.