A review of self-cleaning technology to reduce dust and ice

Feb 1, 2022 · It is proposed that the superhydrophobic coating on the glass surface is an effective self-cleaning technology to solve the icing and dust problems faced by photovoltaic power

Synergistic optimization analysis of droplet cleaning

Jul 1, 2025 · Our research optimizes the self-cleaning technology of photovoltaic module. Research results are expected to further improve the cleaning efficiency and water saving

A review of automatic solar photovoltaic panels cleaning and

Mar 8, 2024 · On the other hand, the methods for cleaning solar photovoltaic panels can significantly improve the effectiveness of power generation and also rise the toughness of

太阳能光伏玻璃亲水或疏水表面的自洁机理及规律,Chemical

Oct 7, 2022 · Self-cleaning mechanisms and laws of hydrophilic or hydrophobic surfaces of solar photovoltaic glass Dust accumulation on solar photovoltaic (PV) glass greatly reduces its

An active self-cleaning surface system for photovoltaic

Sep 21, 2020 · The cover glass is the first interface for the PV modules to interact with the incident photons. It is important to keep this interface clean to ensure the maximum solar power

Soiling, Cleaning, and Abrasion: The Results of the Five-Year

2 days ago · External contamination ("soiling") of the incident surface is a major limiting factor for solar technologies. A 5-year field glass coupon study was conducted to better understand

Photovoltaic glass cleaning methods: an overview | Request

Jan 1, 2016 · For a good efficiency of the system during operation, at bottom, photovoltaic panel surface must be kept clean and so it can be absorb more effective solar radiation. The surface

Photovoltaic glass cleaning methods: An overview

Nov 15, 2016 · The cleaning method of photovoltaic panels such as natural method, electrostatic method, mechanical method and self-cleaning nanofilm method has been discussed in detail

What Is Photovoltaic Smart Glass? | First Glass

Aug 21, 2024 · Transparent Photovoltaic Smart Glass converts ultraviolet and infrared to electricity while transmitting visible light into building interiors,

Droplet cleaning method and water consumption analysis for

Mar 15, 2022 · The results showed that droplet dust removal cleaning method has a broad prospect. Only 0.0383 L/m 2 water is needed to clean the superhydrophobic photovoltaic

Solar PV cleaning techniques contribute to Sustainable

Nov 1, 2022 · The efficiency and power output of photovoltaic (PV) panels are vital to the solar PV plant. Apart from overheating, and natural shading, some geograp

Soiling, cleaning, and abrasion: The results of the 5-year photovoltaic

Sep 15, 2024 · External contamination ("soiling") of the incident surface is a major limiting factor for solar technologies. A 5-year field glass coupon study was conducted to better understand

Droplet cleaning method and water consumption analysis for

Mar 15, 2022 · Established a model for predicting the water consumption of droplet cleaning method based on droplet radius. The mass of dust removed by a droplet has a regression

A novel solar panel cleaning mechanism to improve

May 1, 2022 · Low cost and low-maintenance solar panels cleaning system. Abstract First generation Photovoltaic (PV) systems need regular washing to avoid efficiency degradation.

A transparent superhydrophobic film with excellent self-cleaning

Oct 1, 2023 · Therefore, periodic cleaning of PV glass surfaces is essential to prevent contaminant accumulation. Currently, regular manual cleaning or machine cleaning is still the primary

Laser-induced texturing: A sustainable approach to self-cleaning

Feb 1, 2025 · As per detailed thorough research we did not find any review article related to laser texturing for self-cleaning of solar glass. Sefcondly, the found literature remains limited for the

A review of anti-reflection and self-cleaning coatings on photovoltaic

Mar 15, 2020 · Decreasing sunlight also causes a decrease in electrical power output. Thus, to overcome these problems, photovoltaic solar cells and cover glass are coated with anti

Highly transparent, superhydrophobic, and durable

Jul 20, 2024 · Therefore, the use of coated glass to encapsulate photovoltaic cells resulted in a significant increase in photovoltaic conversion efficiency, and the cell performance remained

Cleaning Method of JA Solar Photovoltaic Modules'' Glass

Mar 27, 2025 · This manual is a detailed description for cleaning the anti-reflection coated glass (referred to as ARC-glass) and the normal tempered glass (referred to as Tempered glass) of

Solar Panel Cleaning Guide: Do''s and Don''ts for

Aug 14, 2024 · Description: Maximize solar panel efficiency with expert cleaning tips. Learn what to do and avoid for increased energy output, longevity, and

How to Clean Photovoltaic Panels ?

Dec 23, 2024 · To ensure photovoltaic (PV) panels produce energy efficiently, they must be cleaned regularly. Dirt, dust, bird droppings, and other contaminants that accumulate on the

A state-of-the-art review on the multifunctional self-cleaning

May 1, 2022 · The solar photocatalytic glass surfaces were identified as green elements in encapsulated glass-to-glass photovoltaic modules and are found to exhibit substantial self

Photovoltaic glass cleaning methods: an overview | 4th IET Clean

Jan 1, 2016 · Thus, there must be the alternative to cleaning photovoltaic glass to reduce dust deposition and enhance photovoltaic efficiency. The cleaning method of photovoltaic panels

Solar PV Panel Cleaning Methods: A Comparative Study

Dec 17, 2024 · In this paper a novel design is presented for the first ever human portable robotic cleaning system for photovoltaic panels, which can clean and maneuver on the glass surface

6 FAQs about [Photovoltaic glass cleaning]

What happens if a photovoltaic glass surface is dust laden?

In this state, the movement speed of the dust laden droplets decreases, and small secondary droplets often separate from the trailing edge. These micro droplets, due to their small size, tend to remain on the photovoltaic glass surface, negatively affecting the thorough cleaning of dust.

Does photovoltaic module have a self-cleaning technology?

Our research optimizes the self-cleaning technology of photovoltaic module. Research results are expected to further improve the cleaning efficiency and water saving advantages of the droplet cleaning method. Current research primarily focuses on the single droplet cleaning.

Can photovoltaic self-cleaning systems save water?

In addition, a volume-regulated cleaning strategy has been developed to maximize water conservation while maintaining high cleaning performance in arid environments. These findings provide actionable guidelines for designing the next generation of water-saving photovoltaic self-cleaning systems.

Do PV modules need to be cleaned regularly?

Accordingly, soiling requires mitigation by frequent cleaning. However, regular cleaning of PV modules can damage glass surfaces and commonly used anti-reflective coatings (ARCs), which typically enable 2–3% or even higher increases in the power output.

Can droplet cleaning efficiency be optimized on superhydrophobic PV glass?

While conventional cleaning methods require amounts of water, the application of droplets cleaning technology on superhydrophobic surfaces offers a more sustainable solution. Our study presents an investigation into the optimization of droplet cleaning efficiency on superhydrophobic PV glass by regulating droplet volume.

How do you paint a photovoltaic panel?

The process is as follows: 1) Clean the surface of the photovoltaic panel with a neutral cleaner and rinse off any residual cleaner with water, allowing the panel to air dry naturally. 2) Apply the coating to the photovoltaic panel using a spraying machine, adjusting the speed and spraying volume as necessary.

Update Information

- Single-glass photovoltaic panel glass thickness

- Grenada double glass photovoltaic modules

- Photovoltaic glass is currently profitable

- Personal work in photovoltaic glass

- Tuvalu photovoltaic conductive glass manufacturer

- Photovoltaic glass separation and sorting equipment

- Is there EVA between the photovoltaic cell and the glass

- Rooftop photovoltaic component glass

- Photovoltaic Glass Greenhouse Ecological Park

- Does photovoltaic glass emit radiation

- Photovoltaic glass 1 1 mm

- Photovoltaic glass 900x400

- Helsinki photovoltaic panel glass

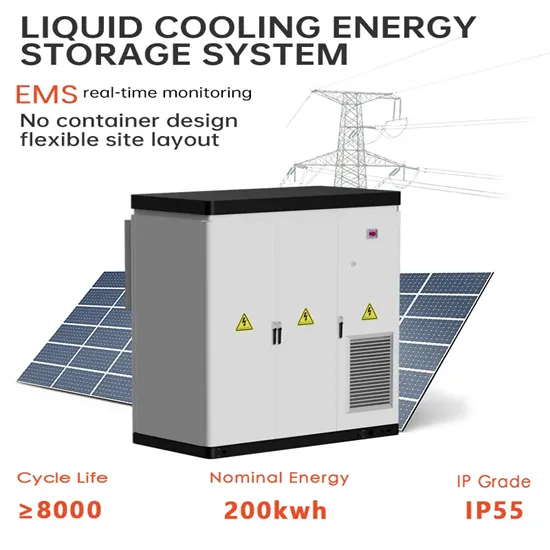

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.