Insights into the Encapsulation Process of Photovoltaic

Aug 14, 2024 · As determined by GC-MS, Silane MPMA is added into this EVA formulation to promote the adhesion between EVA and glass. The amount of silane in the EVA before

Introduction to the use of EVA in glass

Dec 15, 2022 · For this test a laminate is made with glass – EVA and a backsheet material that brings additional stiffness in the test. This backsheet material can

A review of anti-reflection and self-cleaning coatings on photovoltaic

Mar 15, 2020 · The components of a solar panel are, from top to bottom; cover glass, EVA, cells, EVA, and backsheet. Additionally, there is an aluminium metal frame constituting

EVA Sheet: An Important Constituent of a Solar Module;

Aug 1, 2022 · An EVA sheets helps cells float between the glass and back sheet. This arrangement softens shocks and vibrations and, thus, protects the solar cells and its circuits

Classification of Solar Encapsulants

Jun 11, 2023 · Thermoplastic polyolefin (TPO) as being an alternative to conventional EVA encapsulants, are especially engineered via addition of non-crosslinking or crosslinking

Difference between PVB and EVA

The difference between PVB film and EVA film 1. Application field EVA is mainly used for the encapsulation of crystalline silicon cells, and a small number of thin films are also used, mainly

Thermally conductive and electrically insulating EVA

Apr 29, 2008 · Abstract. A new way of improving the heat dissipating ability and PV efficiency of the solar cells by enhancing the ther-mal conductivity of the rear EVA layer was reported. The

Effectively and completely separating the waste crystalline

Jun 22, 2025 · The encapsulation film is typically made of ethylene vinyl acetate (EVA), a polymer material used to bond the interfaces between the solar cell, glass, and backsheet. During the

The causes and effects of degradation of encapsulant

Jan 1, 2018 · Among the elements, which constitute the Si-based PV modules, the encapsulant film constituted by ethylene vinyl acetate copolymer (EVA) has advantages as high

Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · 1. What is solar photovoltaic glass?Solar photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by

Using nanosecond laser pulses to debond the glass-EVA

Oct 1, 2024 · Pulsed laser debonding can be applied to silicon photovoltaic panel recycling. The active silicon cell of a solar photovoltaic (PV) panel is covered by an ethylenevinylacetate

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · This chapter examines the fundamental role of glass materials in photovoltaic (PV) technologies, emphasizing their structural, optical, and spectral conversion properties that

The Anatomy of a Solar Cell: Constructing PV

Sep 30, 2024 · The number of cells connected in series determines the voltage of the module, while the number of parallel cell strings determines the current.

What are Composition and Performance of EVA in Photovoltaic

Dec 10, 2024 · In the booming photovoltaic industry, EVA has attracted much attention as a key photovoltaic material. The so-called EVA is a copolymer of ethylene and vinyl acetate, in which

A comprehensive Review on interfacial delamination in photovoltaic

Jan 1, 2024 · The interfacial bonding with ionomer encapsulant gets facilitated through both hydrogen bonds (between the hydroxyl group over a glass or cell surface to the carboxyl group

Novel encapsulant architecture on the road to photovoltaic

Oct 15, 2018 · As the front EVA foil is the responsible for an effective blocking of the ion migration from the soda-lime glass to the PV cell surface [17], PID test will be performed on the LUV

6 FAQs about [Is there EVA between the photovoltaic cell and the glass ]

Why do solar cells use Eva films?

EVA films exhibit an excellent adhesive bonding to glass, cell, and back sheet. The system is as strong as the bonding of EVA films with other constituents of a solar module. EVA has excellent transparency. Thus, it helps to make optical transmission easy and doesn't block too much of the sunshine from reaching the solar cells.

Are Eva films good for solar panels?

Quality EVA films possess excellent durability. They defend the cells even in difficult weather circumstances, such as high temperature and high humidity. EVA films exhibit an excellent adhesive bonding to glass, cell, and back sheet. The system is as strong as the bonding of EVA films with other constituents of a solar module.

Does Eva film Bond to solar glass?

Under the right circumstances, EVA film will have excellent adhesive bonding to solar glass (NOT standard glass, solar glass has a rough surface). Also EVA bonds very well to the backsheet. EVA is known for its excellent transparency.

Which is better Eva or PVB encapsulation?

The experimental results of thin film photovoltaic module encapsulation indicate that the optical properties of PVB is better than EVA, the adhesion of PVB to photovoltaic cell is better than EVA, while the crosslinked EVA adhered more firmly to glass substrate. Content may be subject to copyright.

What is Eva in solar cells?

Solar cells are sensitive to moisture, oxygen and weather. EVA is a component in a solar module that prevents air and moisture from reaching solar cells and degrading it. If not protected, solar cells will degrade with time and lose their ability to produce energy. What are EVA films?

What is the difference between Eva and PVB chemistry?

Another important difference in the chemistry between EVA and PVB is the adhesion system. PVB is mainly getting its adhesion to glass via hydrogen bonds of the hydroxyl groups of the PVB-film to silanol groups of the glass.

Update Information

- Photovoltaic power generation of exterior wall glass

- Is photovoltaic glass semi-tempered

- U-shaped glass in Dahuang photovoltaic

- How much sunlight does photovoltaic glass need to generate electricity

- How thin is the thinnest photovoltaic glass

- Differences between photovoltaic glass panels in Aarhus Denmark

- How much does Liechtenstein s self-produced photovoltaic glass cost

- How much does a photovoltaic tempered glass cost

- Are the glass of double-glass photovoltaic panels divided into upper and lower parts

- Middle East double glass photovoltaic modules

- Mongolia 300W photovoltaic glass

- Is the glass of photovoltaic panels so brittle

- Panama environmentally friendly photovoltaic glass research and development

Solar Storage Container Market Growth

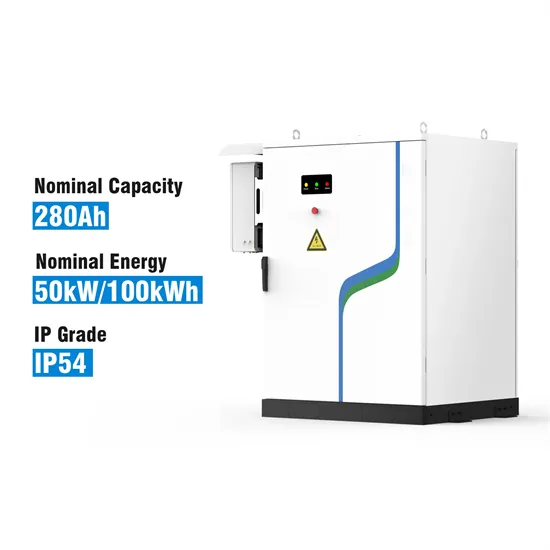

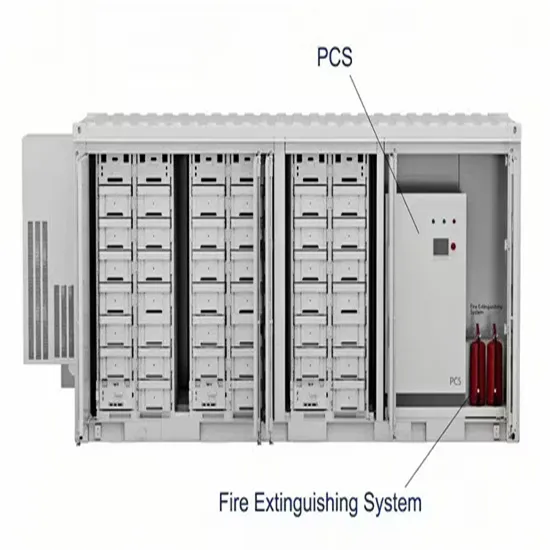

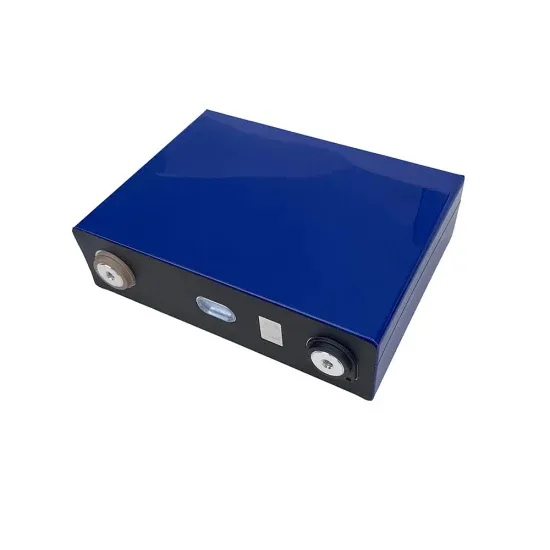

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.